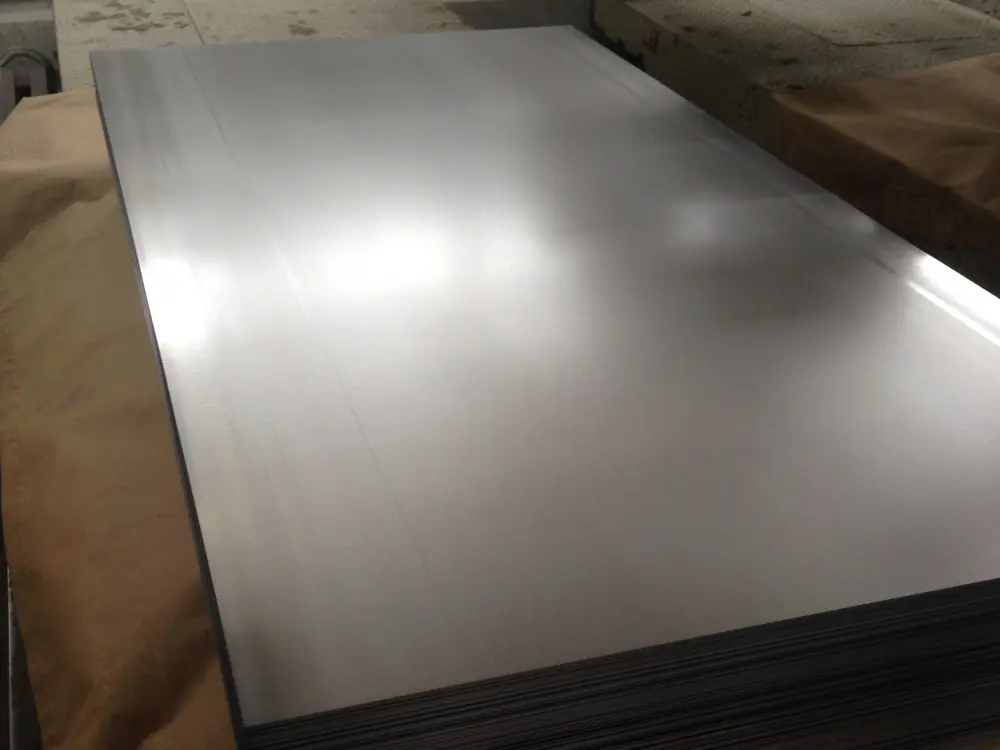

Various types of cold cold-rolled steel sheets with high thermal conductivity

Specification

Product name |

Cold Rolled Sheet |

Standard |

SPCC, SGCC, SGCD, FULL HARD, Q195, Q235, Q345,ST37, ST52 |

Width |

100-2000mm |

Thickness |

0.5-20mm |

Tolerance |

+/-2% |

Product Introduction

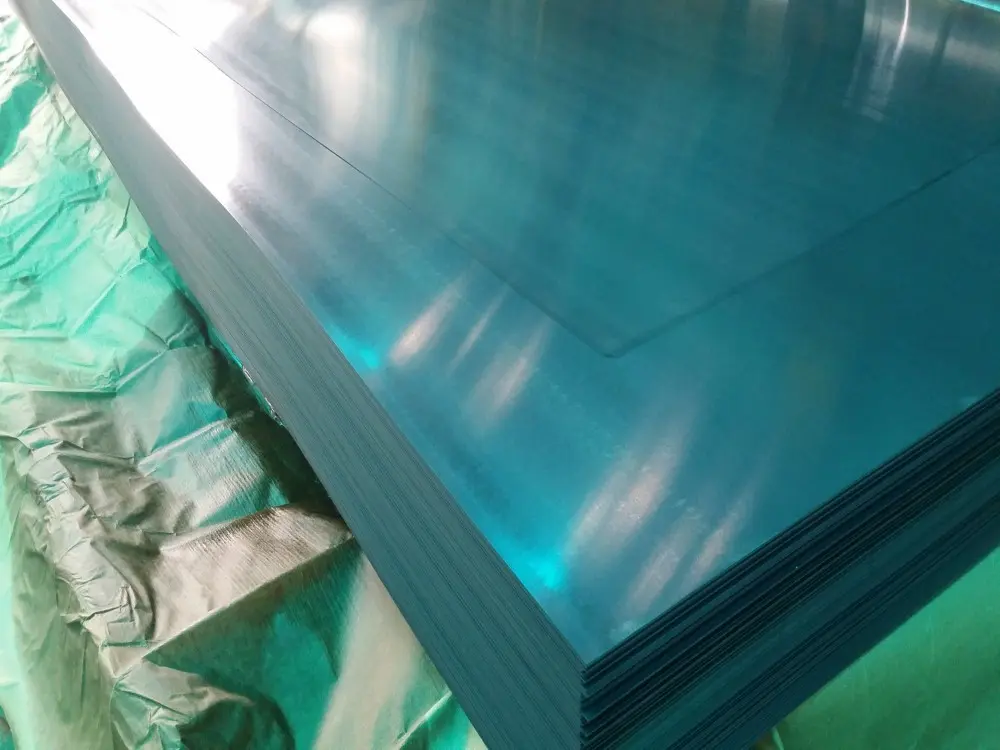

Advantages of cold rolled sheet

1. Better surface properties: Parts made of cold-rolled steel usually have a smooth and shiny surface without scale or rust. Therefore, make them useful when aesthetics are essential.

2. More Strength: They are generally stronger and harder than hot rolled steel (up to 20% stronger). This allows them to be used in high stress applications.

3. Greater precision: Because cold-rolled steel does not shrink when formed, more precise parts can be manufactured with consistent and accurate shapes.

4. Various surface treatments: It supports a wide range of surface treatments.

5.Wide application: Cold plates are usually made of high thermal conductivity materials (such as aluminum or copper), with complex liquid channels or microchannel designs inside, which can quickly conduct heat and improve heat dissipation efficiency.

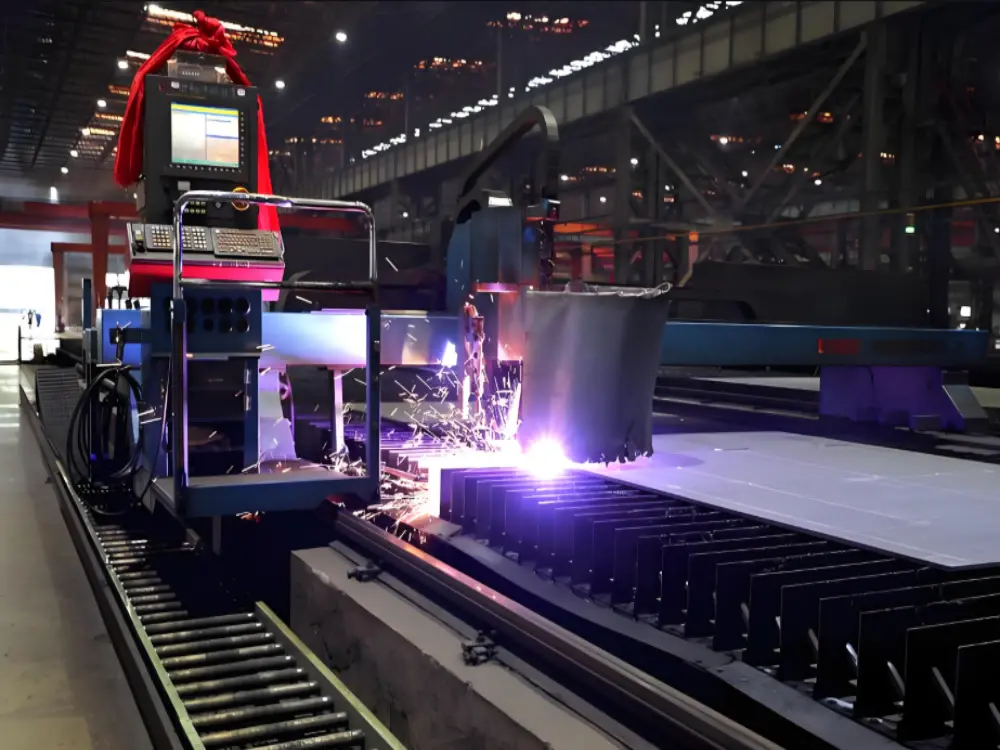

Application Cases

Furniture manufacturing

Fishing equipment

Roof grille

Laboratory table

Machinery manufacturing

Shipbuilding industry

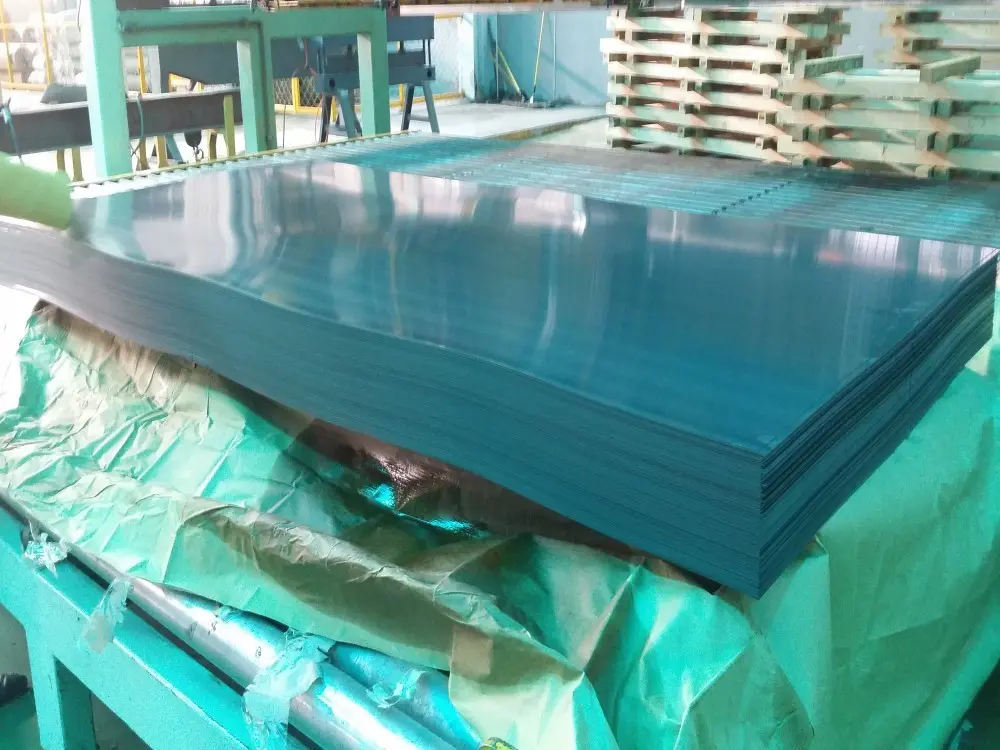

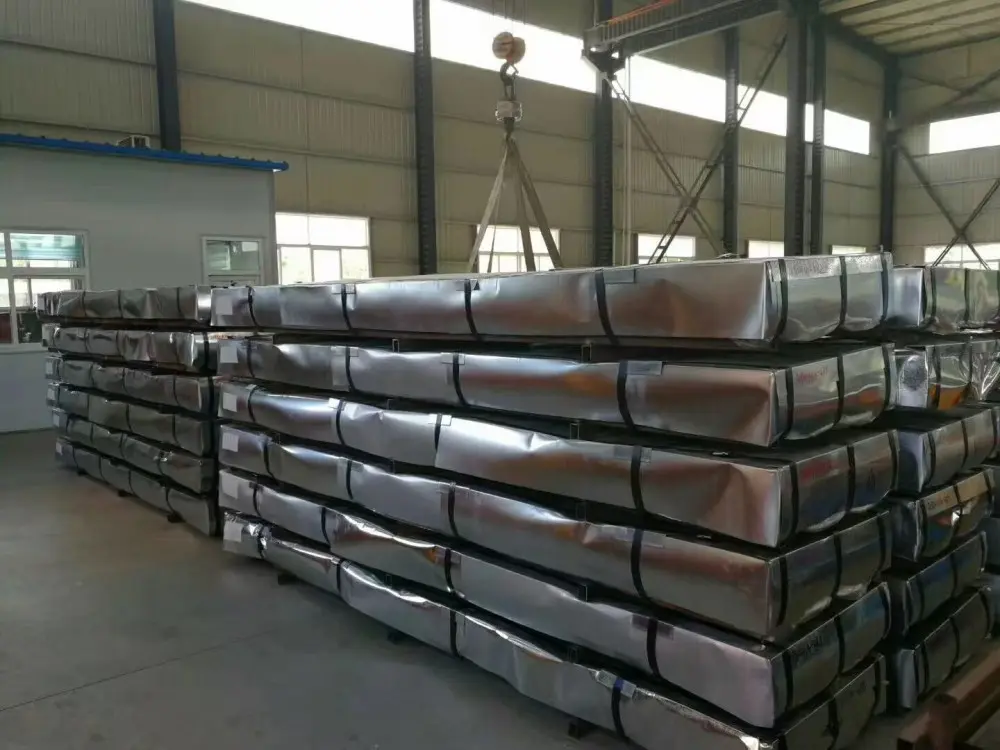

Package&Shipment

Packaging requirements :

Wooden box packaging : For cold plates, it is recommended to use strong wooden boxes for packaging. The crates should be made of good quality wood and of moderate thickness to ensure they can withstand stacking, loading and unloading and vibration and other external forces during transportation.

Moisture-proof and water-proof : Due to the high humidity in the Marine environment, packaging materials should be moisture-proof, especially for moisture-sensitive goods such as cold plates. Moisture-proof paper or plastic film can be laid inside the box to prevent the cold plates from getting wet.

Cushioning materials : Use bubble wrap, pearl cotton and other cushioning materials inside the wooden box to prevent the cold plates from being squeezed or collided during transportation.

Packing requirements :

Use transfer pallets : When loading cold plates, it is recommended to use loading pallets to ensure that the cartons are firmly supported so that the gas can flow smoothly in the cargo.

Package

Shipment