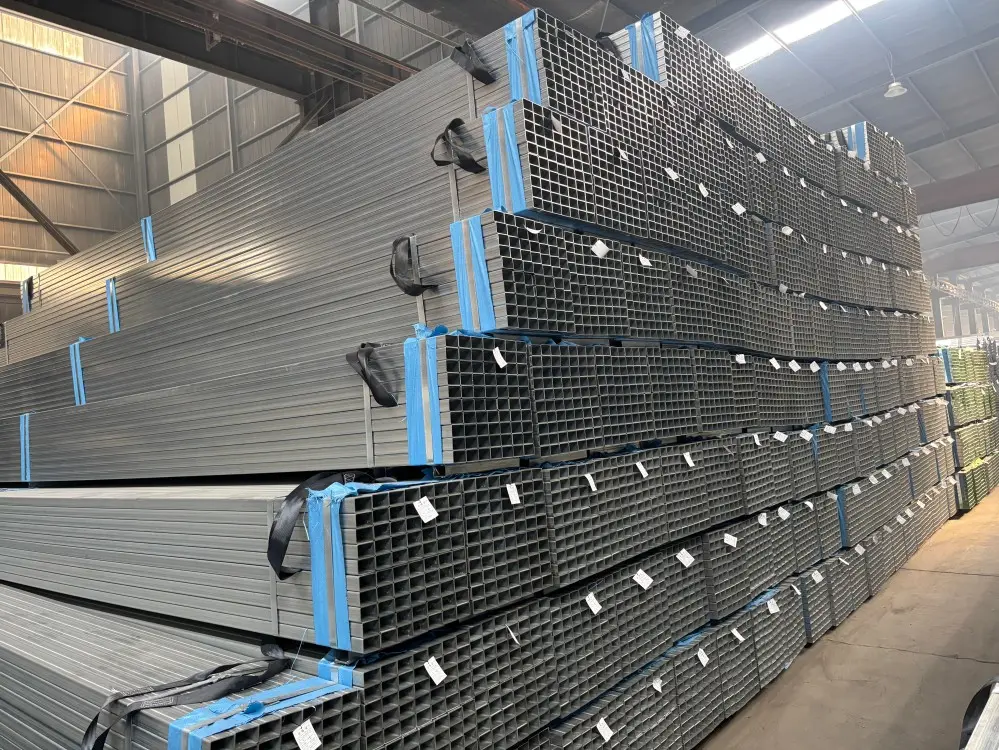

Tianjin Manufature Galvanized Rectangular Steel Pipes Chinese Supplier

Specification

Product name |

Galvanized Square Pipe |

Standard |

ASTM A53, BS1387, ISO65, EN10219, JIS, Q195, Q135 |

Length |

Standard 5.8m and 6m or as customer requirement |

Size |

From 10*10 to 400*400mm |

Thickness |

0.3-20mm |

Technical |

Pre Galvanized Square Pipe |

Zinc Coating |

30g |

Product Advantage

1. Corrosion Resistance

The zinc coating acts as a barrier against moisture, oxygen, and chemicals, significantly extending the pipe's lifespan compared to bare steel pipes.

Ideal for outdoor use (e.g., fencing, handrails) and water supply systems where rust prevention is critical.

2. Durability & Longevity

Can last 20-50 years (or more) depending on environmental conditions.

Resistant to physical damage (scratches, abrasions) due to the tough zinc layer.

3. Cost-Effective

More affordable than stainless steel or copper pipes while still offering good corrosion resistance.

Low maintenance costs (no frequent repainting/replacement needed).

Inspection

Method for detecting hot-dip galvanized layer:

1. Thickness & Coating Measurement

Tools Needed:

Ultrasonic Thickness Gauge – Measures remaining wall thickness.

2. Leak & Pressure Testing

Hydrostatic Test (for Plumbing/Gas Pipes)

Fill the pipe with water.

Pressurize to 1.5× working pressure (e.g., 100 psi for a 65 psi system).

Hold for 15–30 mins – Check for pressure drops or leaks.

Air Pressure Test (for Gas Lines)

Use soapy water on joints to detect bubbles (indicates leaks).

Packing &Shipping

Packaging Methods for Galvanized Pipes

Bundle Packaging (Most Common for Pipes ≤ 6m Length)

Steel Strapping – Pipes are tightly bundled using steel or PP/PET straps (2–4 straps per bundle).

Corner Protectors – Added at pipe ends to prevent strap damage to the zinc coating.

Waterproof Wrapping – Optional plastic film or kraft paper for moisture protection.

Weight Limit per Bundle: Typically 2–5 tons (depends on pipe diameter & logistics).