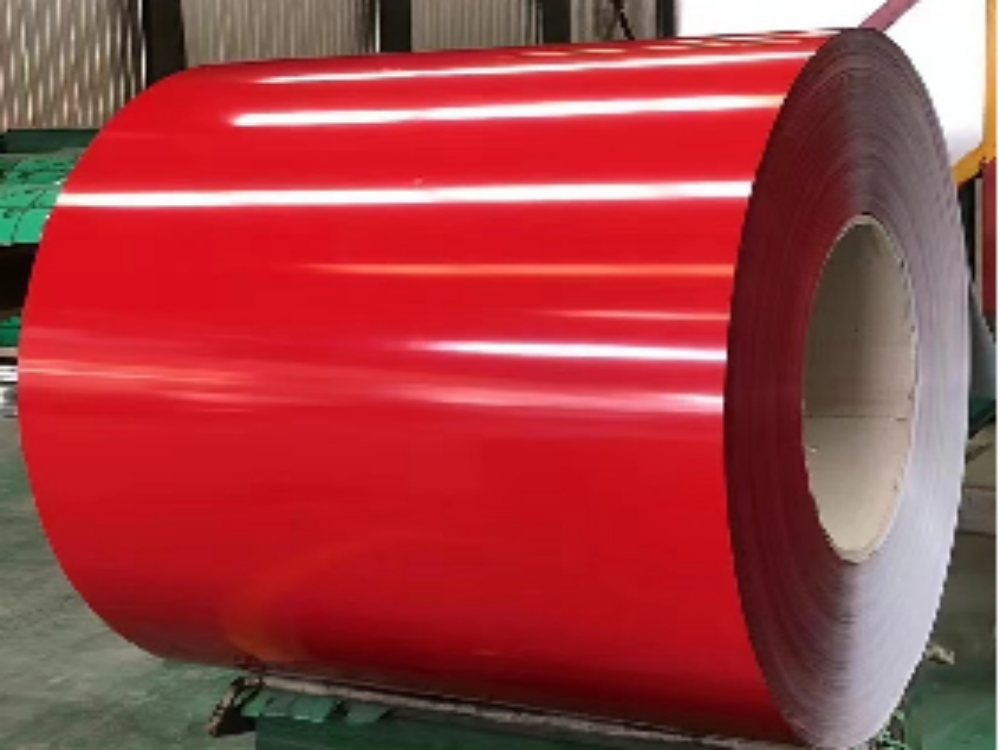

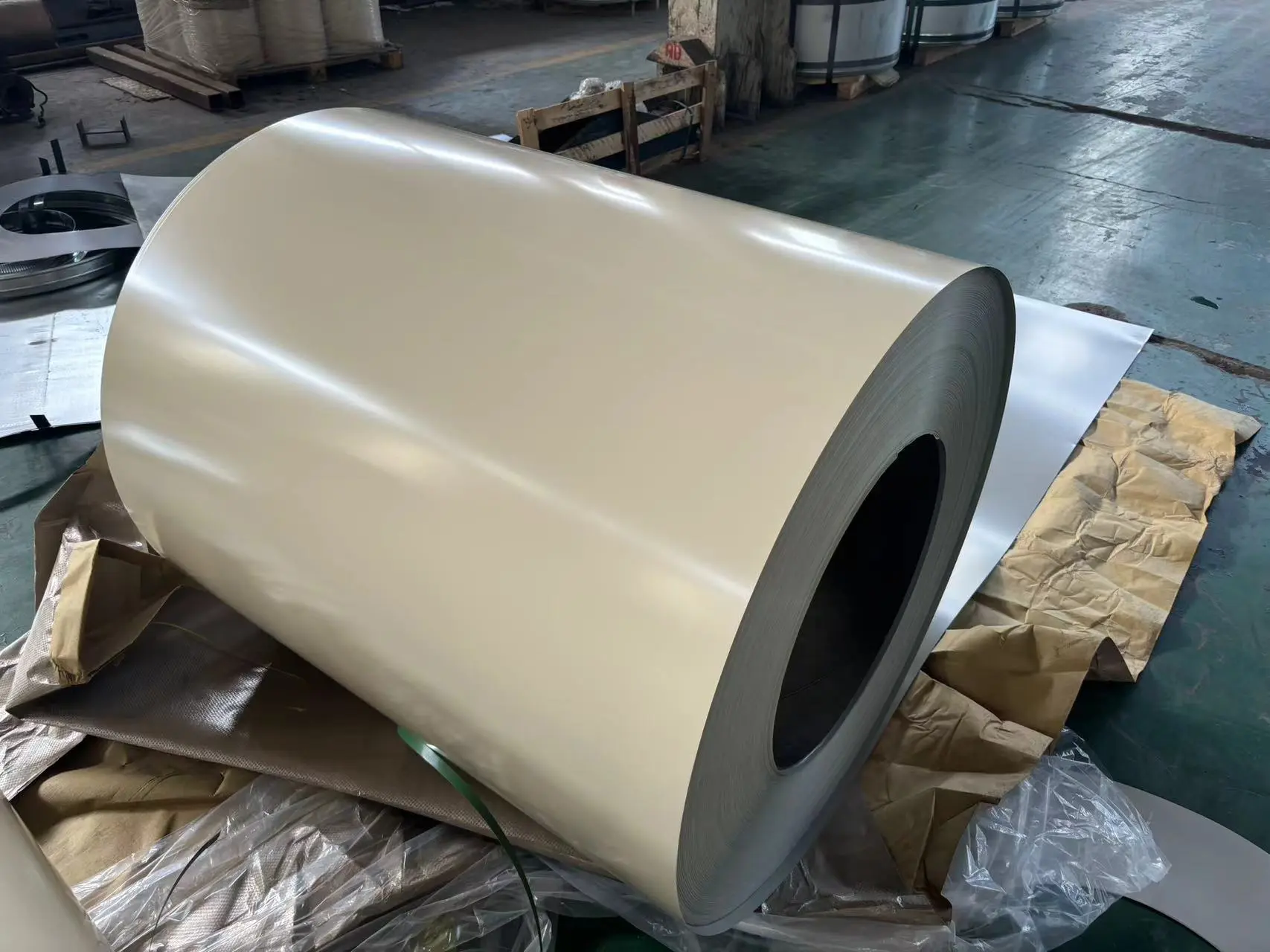

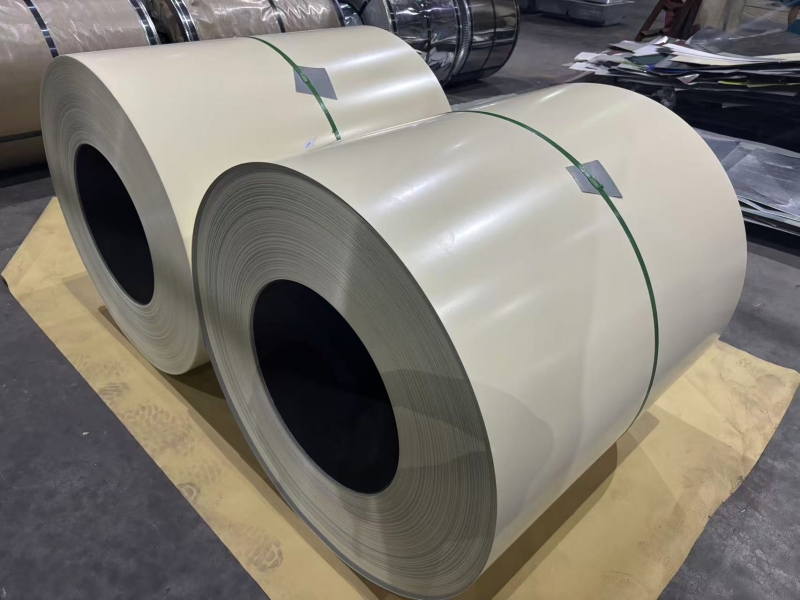

Real Quality 12/5um Z100g Prepainted Coils for Roofing Sheet

Specification

|

Product name |

PPGI Coil |

|

Standard |

SPCC, SGCC, SGCD FULL HARD, DX51D, Q195, Q235 |

|

Width |

500-1500mm |

|

Weight |

About 4 tons |

|

Thickness |

0.11-2.0mm |

|

Tolerance |

±2% |

|

Shipping date |

7-10 days in stock,about 30 days for customized |

|

Place of origin |

Tianjin,China |

Product Introduction

Advantages of hot rolled steel coil

1. Color coated coil has many advantages, including corrosion resistance, durability, heat resistance, heat reflectivity, processing performance and welding performance. Color coated coil is a kind of steel with organic coating on the surface. It has various colors and is widely used in many fields.

2. Home appliance industry: In the home appliance industry, color coated coil is used to manufacture refrigerators, freezers, bread machines, furniture, etc. Its wear resistance, anti-corrosion and easy cleaning characteristics make it an ideal choice for home appliance shells.

3. Transportation Industry: Although color-coated coils are not as widely used in the transportation industry as the first two, they are still used to manufacture parts such as oil pans and automotive interiors. Its light weight, high strength, corrosion resistance and wear resistance make it also have certain applications in the transportation field

4. Application and advantages of color coated coil in different fields

5. Other fields: Color-coated coils are also used in the advertising industry, electrical industry, furniture industry and transportation industry. Its good mechanical structure performance, aesthetics, corrosion resistance, flame retardancy and easy processing make it widely used in many fields.

Application Cases

Construction

Home appliance industry

Transportation industry

Automobile manufacturing

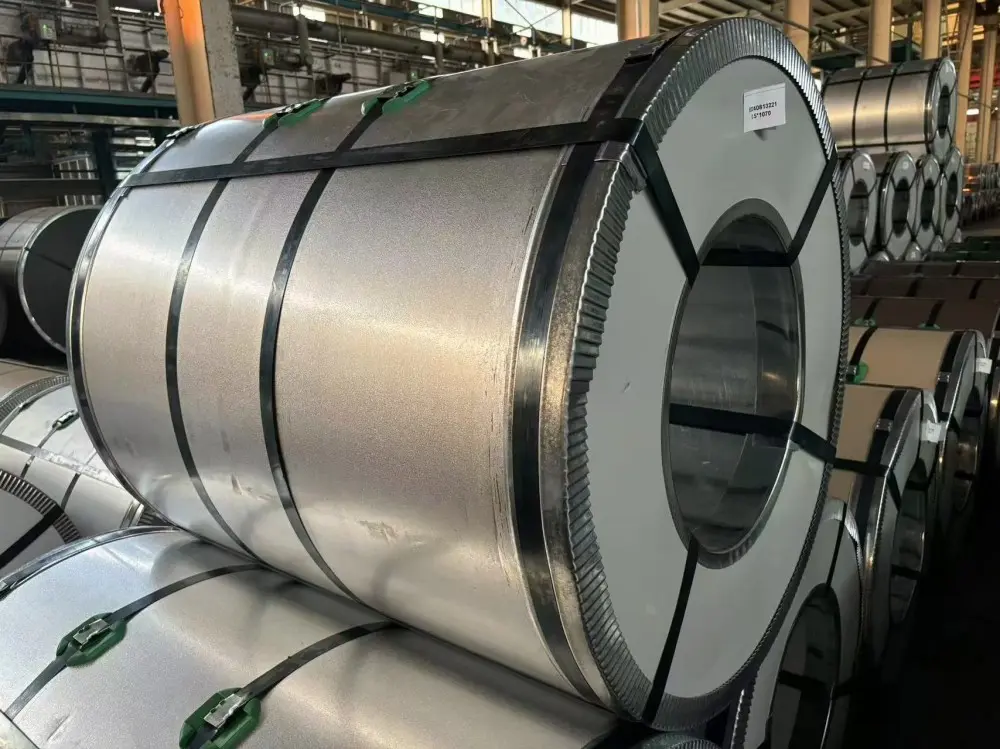

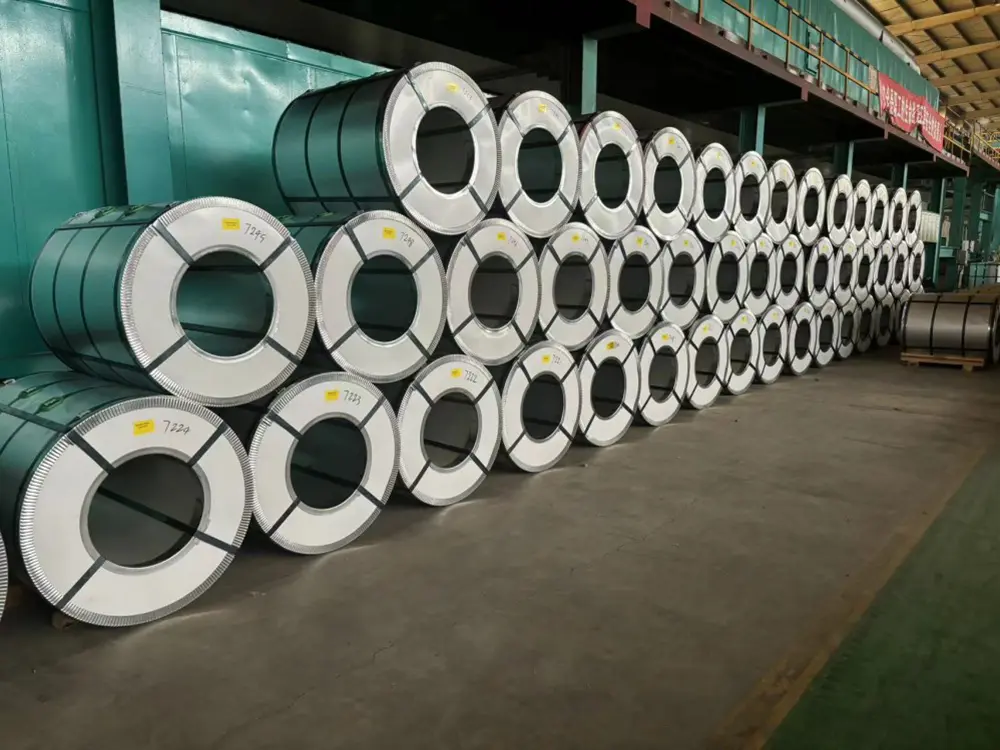

Package&Shipment

The vehicle transporting color-coated coils should be kept clean, and rubber pads or other protective devices should be laid on the floor of the vehicle to prevent the color-coated coils from sliding or colliding during transportation.

Package

Shipment