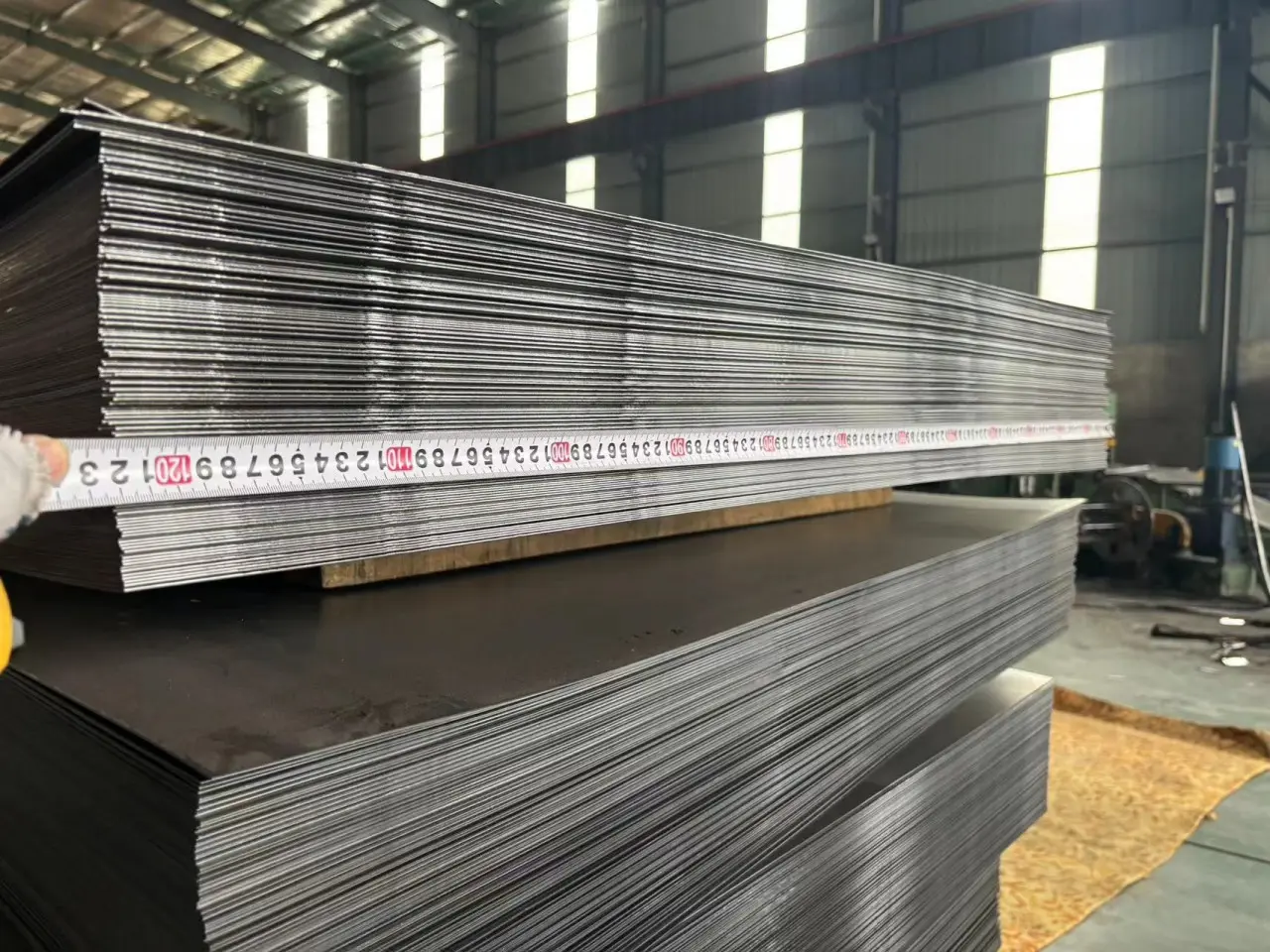

Hot rolled steel sheets with extremely high welding strength and steaming hot

Specification

Product name |

Hot Rolled Steel Sheet |

Standard |

SPCC, SGCC, SGCD, FULL HARD, Q195, Q235, Q345,ST37, ST52 |

Width |

700-2000mm |

Thickness |

0.8-20mm |

Tolerance |

+/-2% |

Product Introduction

Advantages of hot rolled sheet

1. High production efficiency, low cost : The hot rolling process is carried out at high temperature, the plasticity of the metal improves, it is easier to form, suitable for large-scale continuous production, thereby reducing cost.

2. Good plasticity and toughness : The microstructure formed when hot-rolled steel is rolled at high temperature and cooled gives the material better ductility and impact toughness.

3. High strength, good toughness : Hot-rolled products have the characteristics of high strength and good toughness, suitable for applications requiring high strength and high toughness.

4. Easy to form and good weldability : Hot-rolled steel is easy to form and also has good weldability, suitable for a variety of processing methods.

5.The equipment has high stability: The hot plate welding equipment maintains good stability, ensuring consistent welding results and high accuracy of the workpiece after processing.

Application Cases

Food testing equipment

Precise instrument

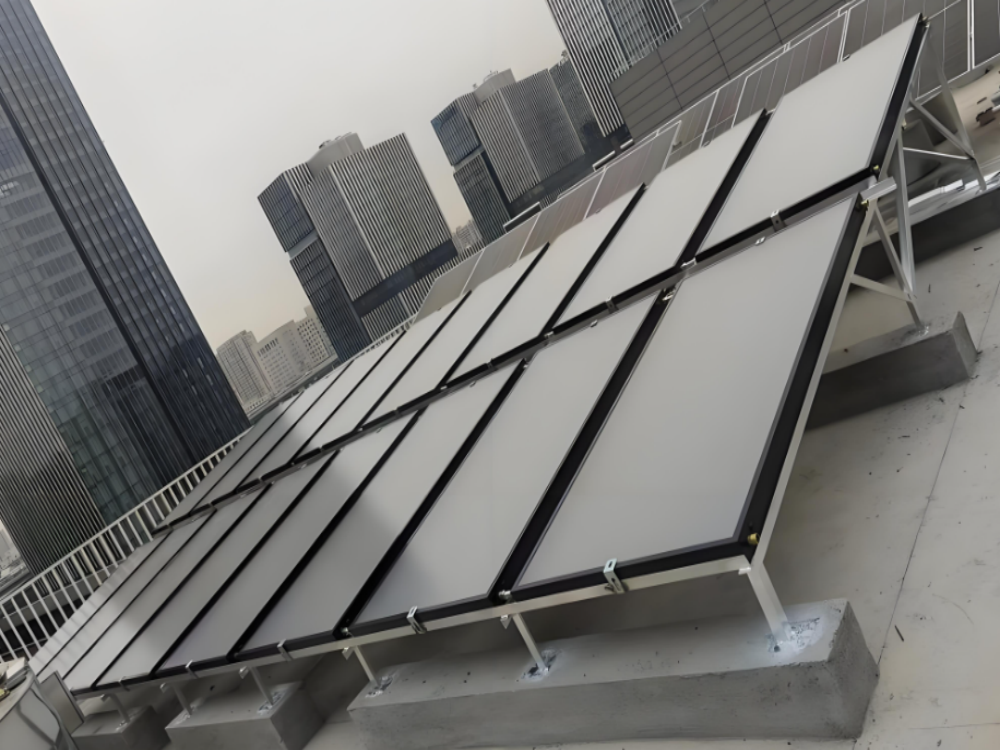

Solar thermal collector

The field of biopharmaceuticals

Steel pipe processing

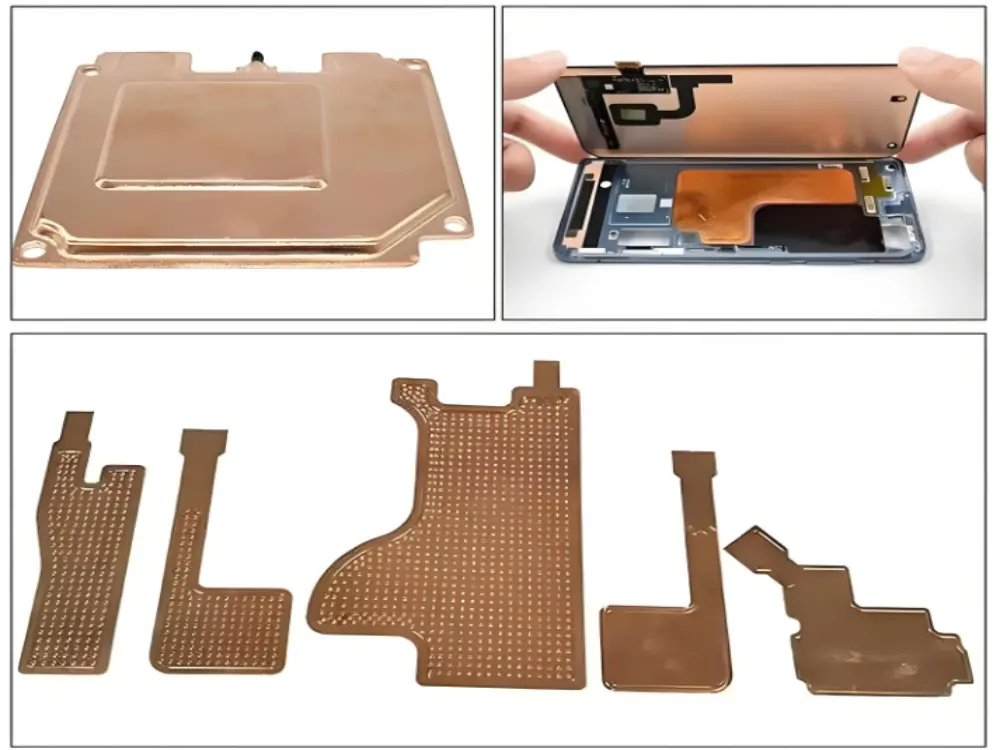

Various types of vapor chambers

Package&Shipment

The sea transportation of hot plates is closely related to packaging . During sea transportation, the quality and selection of packaging are crucial for the protection of hot plates. The following are the relevant requirements and best practices for packaging in the sea transportation of hot plates:

Moisture-proof and water-proof : Due to the high humidity in the Marine environment, the packaging materials should have good moisture-proof and water-proof performance. Especially for moisture-sensitive goods such as hot plates, packaging should be made of waterproof material to prevent the goods from getting wet.

Shock protection : For fragile items such as hot plates, proper cushioning and local protection measures should be taken. The goods CAN be filled and protected with materials such as bubble wrap, pearl cotton, EPS or EPE foam plastic, ETC. to prevent DAMAGE during transport.

Reinforcement measures : Use packing straps, stretch film or other reinforcing structures to ensure the stability of the package. For heavy cargo, strong packing straps at the junction of the cartons can be used for further reinforcement.

Package

Shipment