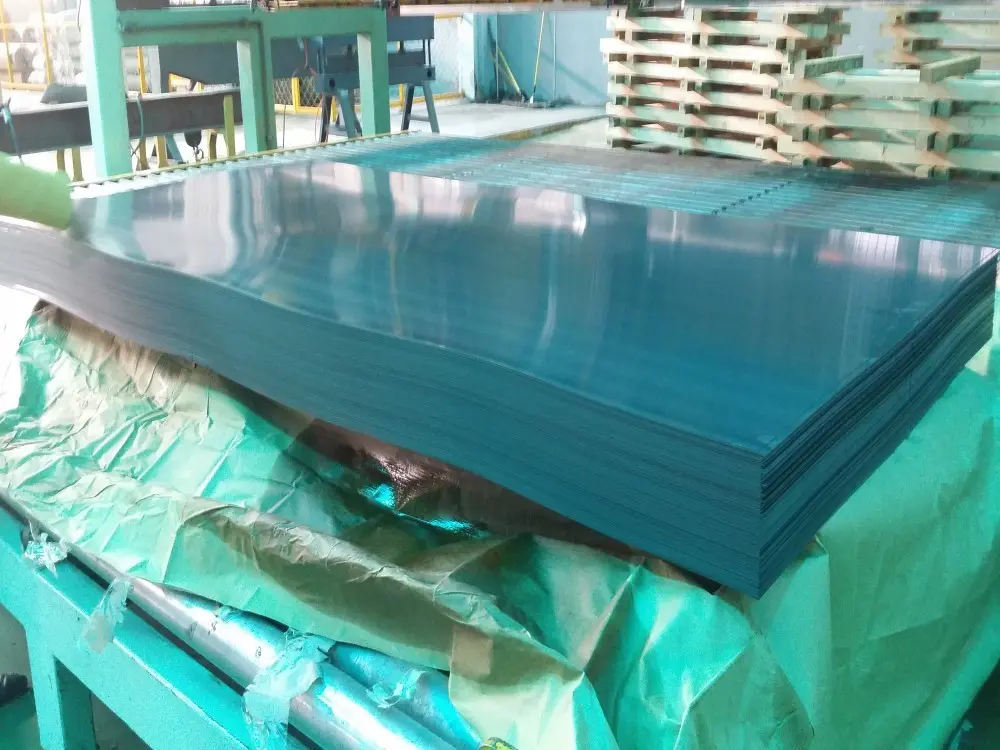

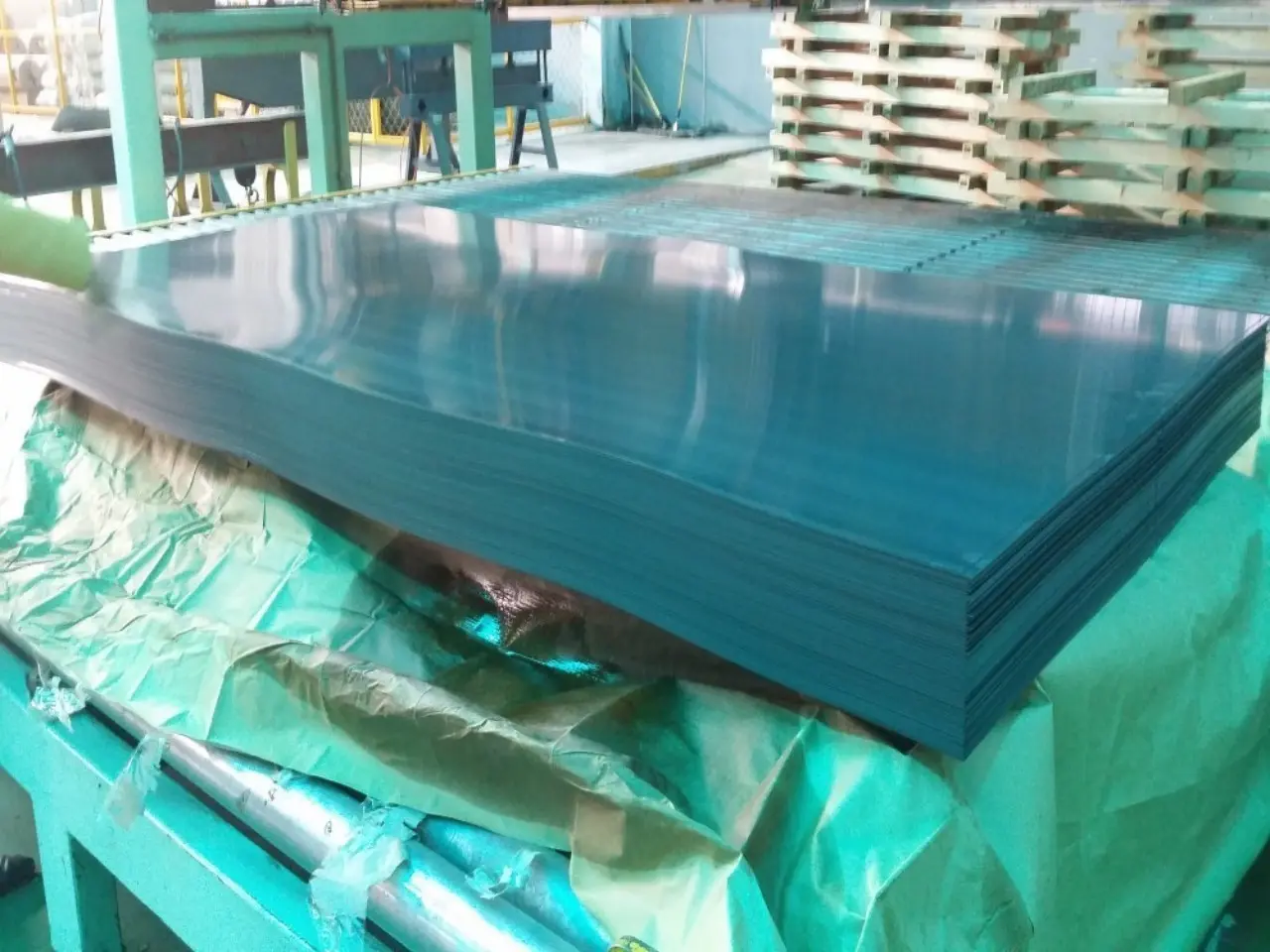

Carbon Cold Rolled Sheets Automotive Machinery Manufacturing Cr

Specification

Product name |

Cold Rolled Sheet |

Standard |

SPCC, SGCC, SGCD, FULL HARD, Q195, Q235, Q345,ST37, ST52 |

Width |

100-2000mm |

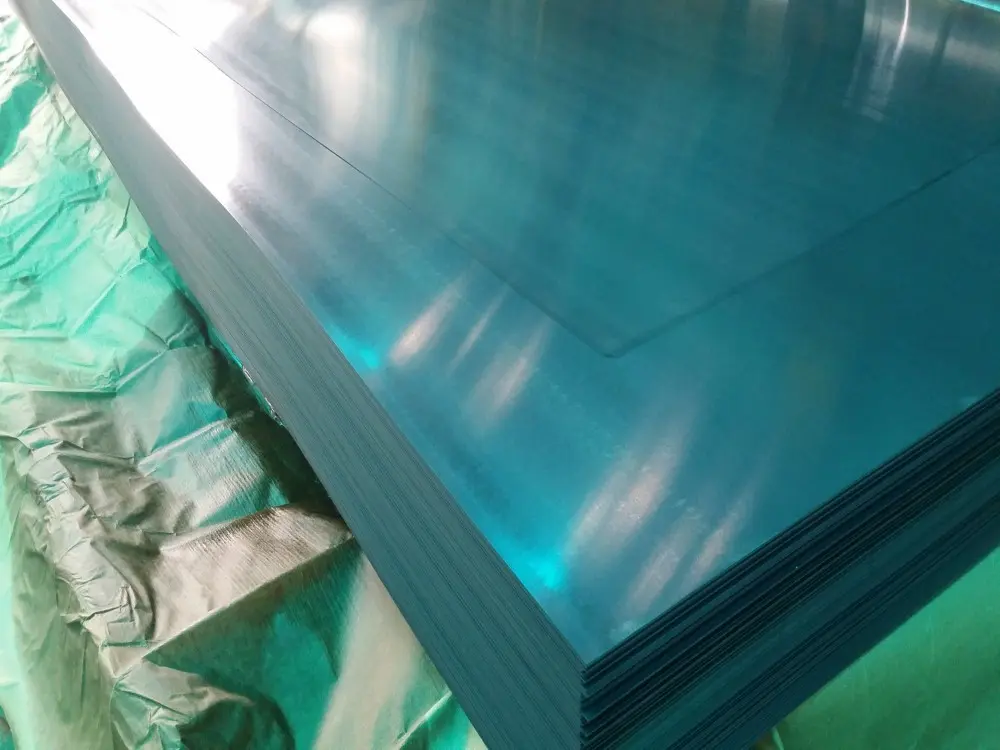

Thickness |

0.5-20mm |

Tolerance |

+/-2% |

Product Introduction

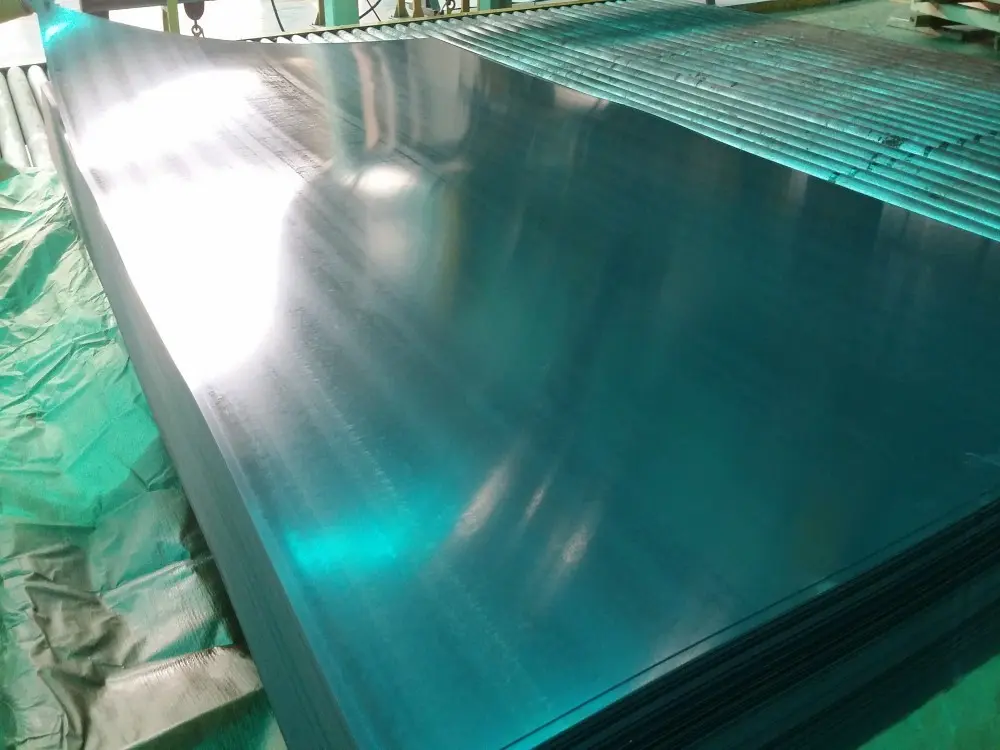

Advantages of cold rolled sheet

1. Better surface properties: Parts made of cold-rolled steel usually have a smooth and shiny surface without scale or rust. Therefore, make them useful when aesthetics are essential.

2. High-efficiency heat dissipation: The cold plate, through the coolant circulation system, can efficiently transfer heat from the heat source (such as electronic components, batteries, cpus, etc.) to the cooling medium, thereby achieving rapid cooling and preventing the equipment from overheating.

3. Greater precision: Because cold-rolled steel does not shrink when formed, more precise parts can be manufactured with consistent and accurate shapes.

4. Processing performance and welding performance: Cold plates have high dimensional accuracy, with very small thickness and width errors, making them suitable for high-precision production requirements. It has excellent mechanical properties and high strength, making it suitable for various processing requirements.

5.Wide application: Cold plates are widely used in the cooling of electronic devices, battery cooling (especially in electric vehicle applications), data center cooling, laser or medical equipment cooling, and industrial fields.

Application Cases

Furniture manufacturing

Fishing equipment

Roof grille

Laboratory table

Machinery manufacturing

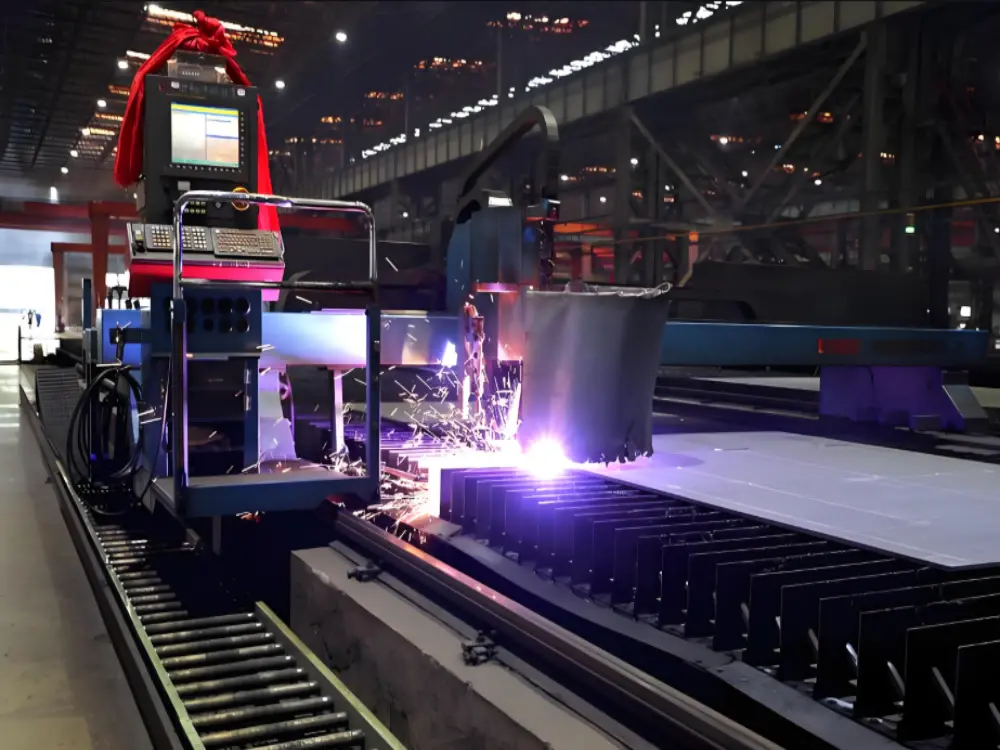

Shipbuilding industry

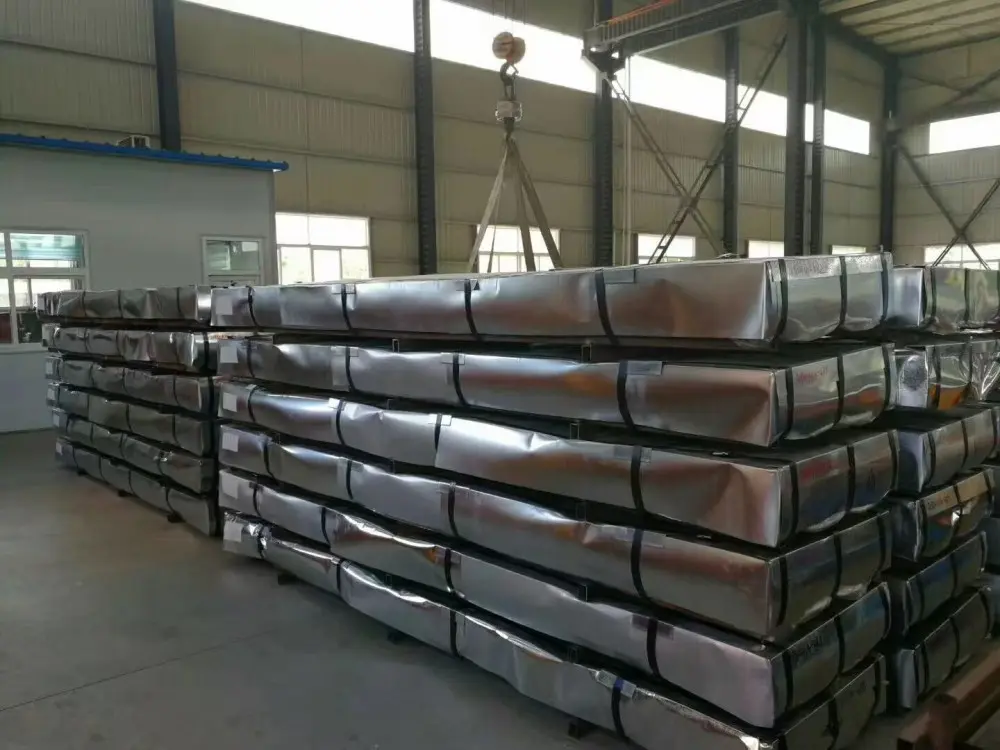

Package&Shipment

Package

Shipment