Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

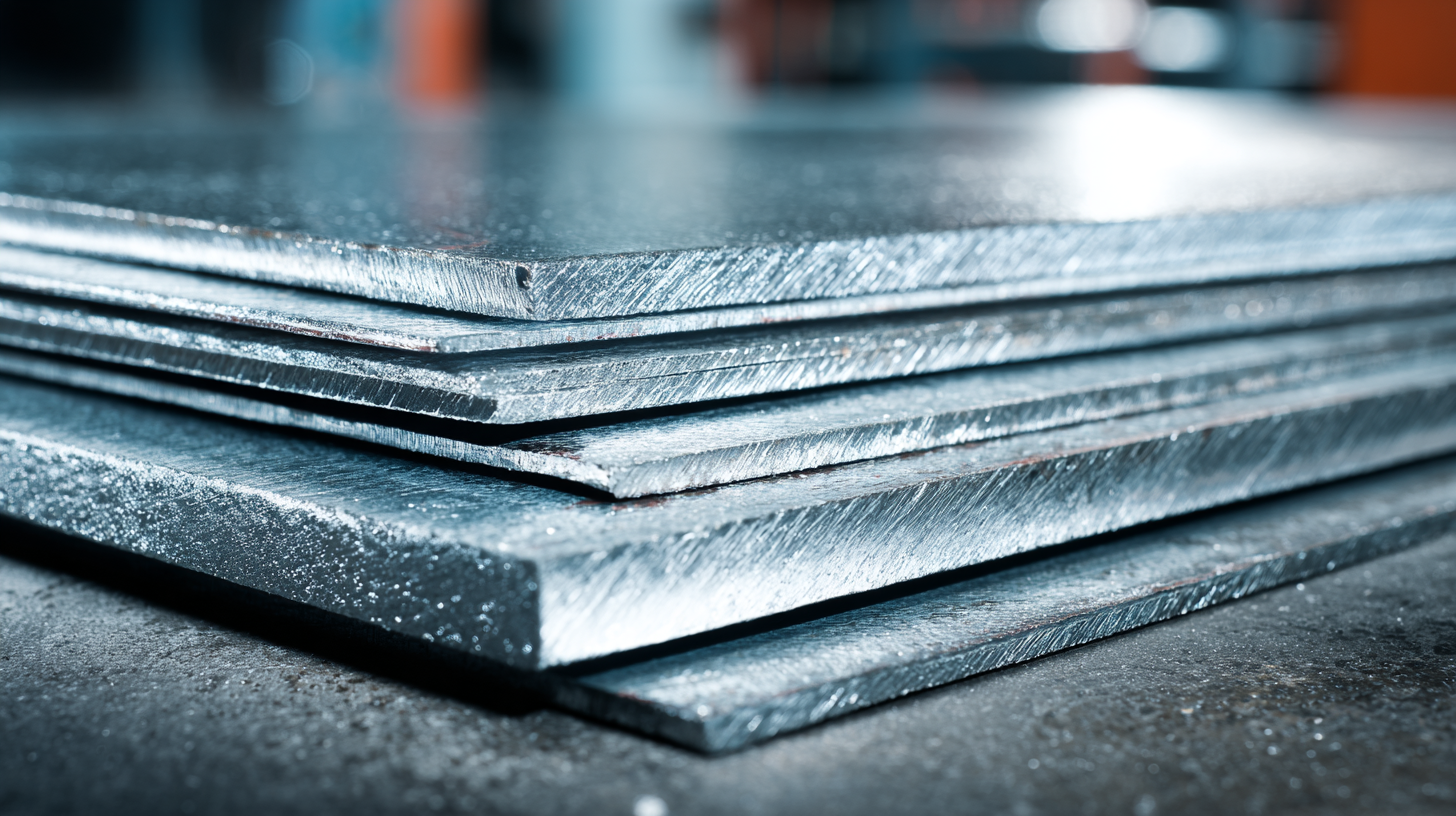

Galvanized Steel Sheet is a material renowned for its durability and versatility, playing a crucial role across various industries. According to a recent report by the International Steel Association, the global demand for galvanized steel products is projected to reach 180 million tons by 2025, reflecting its increasing application in construction, automotive, and manufacturing sectors. Its ability to resist corrosion while maintaining structural integrity makes it an ideal choice for building frameworks, roofing, and even home appliances. Innovations in the production of Galvanized Steel Sheets, including advancements in zinc coating technologies, are also enhancing their performance and sustainability. As industries continue to prioritize materials that are not only strong but also eco-friendly, galvanized steel sheets are emerging as a preferred option, reinforcing their significance in modern engineering and design.

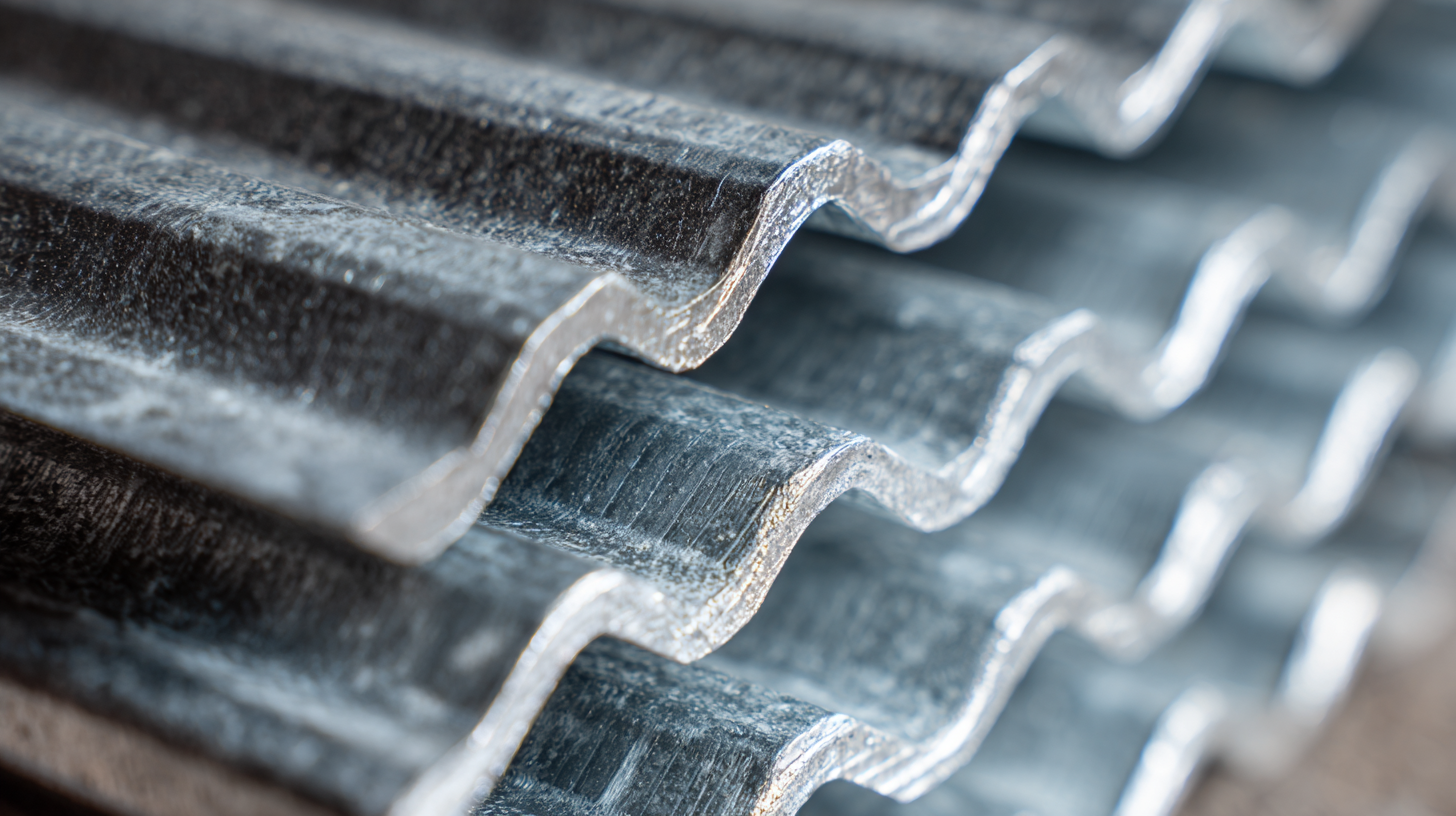

Galvanized steel sheets have gained significant traction in the construction and architecture sectors due to their durability and corrosion resistance. According to a report by MarketsandMarkets, the global galvanized steel market is projected to reach approximately $139 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.7% from 2021 to 2026. This growth is spurred by the increasing demand for sustainable building materials that can withstand harsh environmental conditions, making galvanized steel an ideal choice for roofing, sidings, and structural supports.

Galvanized steel sheets have gained significant traction in the construction and architecture sectors due to their durability and corrosion resistance. According to a report by MarketsandMarkets, the global galvanized steel market is projected to reach approximately $139 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.7% from 2021 to 2026. This growth is spurred by the increasing demand for sustainable building materials that can withstand harsh environmental conditions, making galvanized steel an ideal choice for roofing, sidings, and structural supports.

In architectural applications, galvanized steel sheets are often utilized in both structural and aesthetic capacities. For instance, their lightweight nature allows for innovative design options without compromising structural integrity. A study by the American Institute of Steel Construction indicates that using galvanized steel can reduce maintenance costs by up to 30% compared to non-galvanized alternatives, which further enhances its appeal to builders and architects. The versatility of galvanized steel sheets not only caters to functionality but also ensures longevity, as they retain their aesthetic appeal even after decades of exposure to the elements, thereby making them a favored choice in modern construction projects.

Innovative techniques in the production of galvanized steel sheets are transforming how this versatile material is utilized across various industries. For instance, recent advancements, such as the Dual Stone technology, enable manufacturers to create finishes that closely resemble natural stone on steel sheets. This not only broadens aesthetic options for architectural projects but also enhances the product’s market appeal. Additionally, the integration of eco-friendly practices in steel production is becoming increasingly prevalent, as seen with the push towards "green steel" initiatives, aligning with global sustainability goals.

Tips: When considering galvanized steel sheets for your projects, always look for suppliers who employ cutting-edge production techniques, as this can significantly affect quality and longevity. Moreover, keep an eye on market trends which indicate a growing demand for innovative finishes that can harmonize with modern design preferences. Understanding these trends can help you make informed decisions in your material selection process, ultimately leading to better project outcomes.

Galvanized steel sheets have gained significant traction in modern industries, primarily due to their impressive environmental benefits. By applying a protective zinc coating, these sheets resist rust and corrosion, significantly extending their lifespan compared to non-galvanized alternatives. This durability results in less waste generated from replacements and repairs, making galvanized steel sheets a sustainable choice for construction, automotive, and appliances. Furthermore, their recyclability contributes to a circular economy, allowing materials to be repurposed at the end of their lifecycle, reducing the environmental footprint.

Tips: When considering galvanized steel for your projects, always check for the appropriate coating thickness to match your specific application needs. Additionally, ensure that you source your materials from suppliers that prioritize sustainable practices to further enhance the environmental benefits of your choice.

Moreover, the lightweight nature of galvanized steel sheets leads to lower transportation emissions. Their adaptability in various settings—from roofing to piping—means companies can utilize them to create energy-efficient infrastructure. Adopting this versatile material not only supports environmental stewardship but can also lead to significant cost savings over time due to their long-term reliability and reduced maintenance requirements.

Tips: Opt for local suppliers of galvanized steel sheets to reduce transportation emissions and support local economies, making your project more environmentally responsible while maintaining quality and efficiency.

Galvanized steel sheets have emerged as a staple in various manufacturing sectors due to their unique combination of strength and corrosion resistance. This cost-effective material allows manufacturers to reduce maintenance costs significantly while ensuring a longer lifespan for their products. The galvanization process, which involves coating steel with a layer of zinc, not only enhances durability but also provides a protective barrier against environmental elements, making it an ideal choice for outdoor applications.

Moreover, the versatility of galvanized steel sheets extends across different industries, from construction to automotive manufacturing. This adaptability results in economies of scale, as the same material can be used for multiple purposes, thereby lowering production costs. Additionally, the availability of galvanized steel in various thicknesses and forms enables manufacturers to tailor solutions to specific project requirements without incurring high expenses. As industries continue to seek ways to balance quality and cost, galvanized steel sheets stand out as a reliable choice that meets both needs effectively.

This chart illustrates the cost-effectiveness of galvanized steel sheets compared to alternative materials over various applications. The comparison includes Manufacturing, Construction, Automotive, and Appliance sectors.

In recent years, the galvanized steel sheets market has been witnessing a considerable transformation, with significant growth projected for the future. By 2033, the electrolytic zinc market is expected to expand from approximately $54.49 million in 2025 to a staggering $131.1 million, reflecting a compound annual growth rate (CAGR) of 11.6%. This growth can be attributed to the increasing demand from various sectors, especially in solar photovoltaic (PV) applications where competition between materials such as aluminum and galvanized steel frames is heating up.

Tips: When choosing materials for solar applications, consider the long-term sustainability and durability of galvanized steel sheets. They offer excellent corrosion resistance, ensuring longevity in outdoor conditions, which is crucial for the efficiency of solar energy solutions.

As the global market evolves, innovations in galvanized steel processing and fabrication will drive its integration across diverse industries. For instance, the efficient use of galvanized steel in building infrastructure, automotive manufacturing, and renewable energy systems illustrates its versatility. The ongoing advancements in the zinc smelting industry reflect a future-focused approach, with a shift toward automation and environmentally friendly practices.

Tips: Keep an eye on emerging trends in material science that may lead to even more efficient and eco-friendly applications of galvanized steel. Exploring these innovations can help industries stay ahead in a competitive market while contributing to sustainability efforts.