Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Cold Rolled Coils have revolutionized the manufacturing landscape. These coils are crucial in producing various products, from automotive parts to appliances. According to a recent report by MarketsandMarkets, the global cold rolled steel market is projected to reach $150 billion by 2026, indicating significant growth.

The manufacturing industry relies heavily on Cold Rolled Coils for their strength and finish. They provide excellent surface quality and dimensional tolerances. Interestingly, 70% of cold rolled steel is used in the automotive sector, emphasizing its importance. However, many manufacturers still face challenges in production efficiency and cost management, urging a need for innovative approaches.

There’s a disparity in utilizing Cold Rolled Coils effectively. While some companies maximize their potential, others overlook opportunities. This inconsistency can lead to wasted resources and potential losses. Manufacturers need to reflect on their processes and adapt to changing demands in this competitive market.

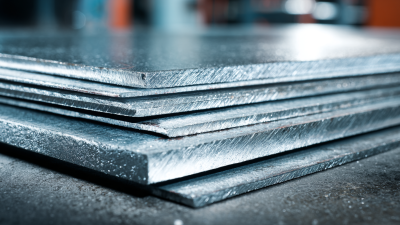

Cold rolled coils are crucial in manufacturing. They are produced by passing hot-rolled steel through rollers at room temperature, which improves surface finish and dimensional accuracy. The process enhances strength and hardness. These coils typically feature a thinner gauge, essential for applications like automotive and appliances.

According to industry reports, cold rolled steel can achieve a yield strength of approximately 270 MPa. This provides significant advantages in design flexibility and durability. The fine surface texture is ideal for painting and coating, making cold rolled coils suitable for varied finishes. However, it’s essential to note that handling requires care. Improper storage may lead to rust or other surface issues.

The dimensional tolerance of cold rolled coils is tighter than that of hot rolled products, often reaching ±0.01mm. Yet, this precision is not always guaranteed. Factors like equipment maintenance and operator skill directly impact quality. Manufacturers must continuously evaluate their processes and standards to ensure the optimal use of these coils.

| Property | Value | Application |

|---|---|---|

| Thickness | 0.3 - 3.0 mm | Automotive parts |

| Width | 600 - 2000 mm | Furniture manufacturing |

| Surface Treatment | Pickled, Oiled | Electrical appliances |

| Yield Strength | 200 - 350 MPa | Structural components |

| Elongation | 10 - 25% | Metal stamping |

| Finish | Smooth | Appliance housing |

Cold rolled coils have become a staple in various manufacturing processes. Their advantages are numerous. They provide increased precision in dimensions and better surface finish compared to hot rolled products. This can lead to less waste during production. According to industry reports, companies often save about 15% on raw material costs by utilizing cold rolled steel.

Tips for using cold rolled coils effectively include ensuring proper storage. Moisture can negatively impact the quality of the coils. Additionally, using the right tools during processing can enhance the efficiency of operations. Cold rolled coils are often softer and easier to work with. This can contribute to faster production cycles, yet some manufacturers overlook the benefits of precise tooling.

The impact on product durability is significant. Cold rolled coils exhibit superior mechanical properties, essential for components in automotive and aerospace industries. However, challenges persist. Some manufacturers struggle with the machining of cold rolled materials due to their varying hardness levels. Understanding the right application can mitigate these issues.

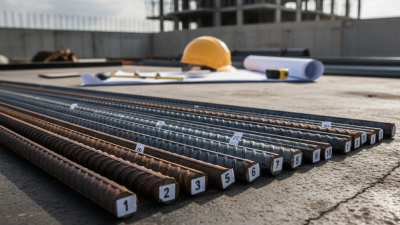

Cold rolled coils are essential in various industries. Their high strength and superior surface finish make them ideal for multiple applications. In the automotive sector, for instance, cold rolled steel is often used in manufacturing body panels, chassis components, and structural supports. According to industry reports, around 30% of cold rolled steel usage is in automotive manufacturing, highlighting its significance in enhancing vehicle safety and durability.

In construction, cold rolled coils are integral to producing building materials such as metal studs and roofing sheets. These materials provide excellent tensile strength while keeping the weight in check. Additionally, the energy-efficient properties of cold rolled products contribute to sustainable building practices. The construction industry accounts for approximately 20% of the cold rolled steel market, reflecting its growing role in modern architecture.

However, not every application is without challenges. Despite their advantages, cold rolled coils can suffer from issues like surface defects during production. These imperfections affect the final product's aesthetic and functional qualities. The industry must continuously innovate processes to minimize such defects and enhance overall quality. Balancing cost efficiency with quality remains a critical focus for manufacturers.

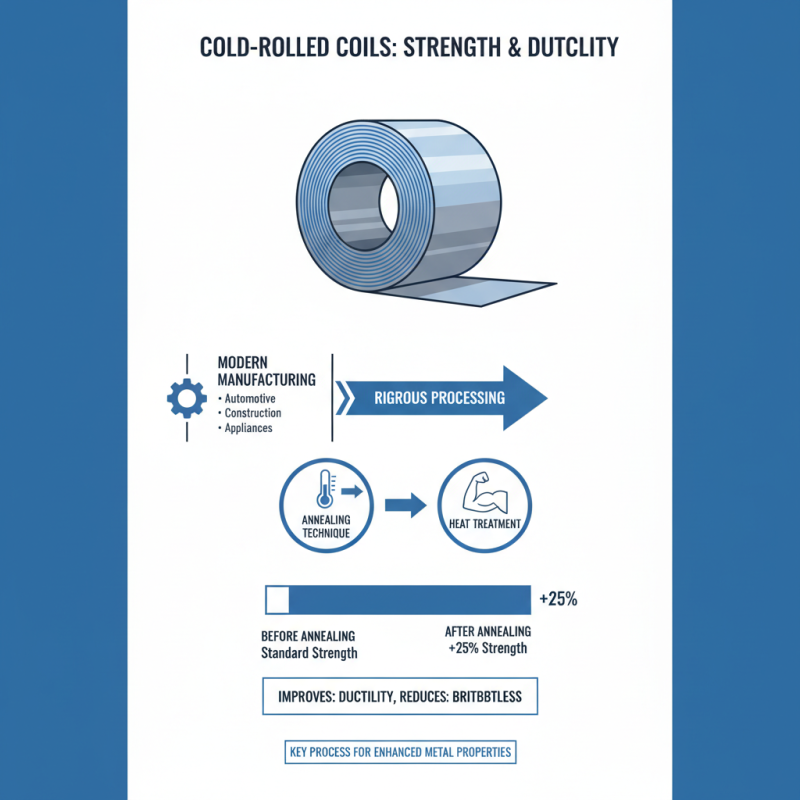

Cold rolled coils are vital in modern manufacturing. These coils undergo rigorous processing techniques that enhance their mechanical properties. One common method is annealing. This technique involves heating the coils to various temperatures, improving ductility and reducing brittleness. Studies show that proper annealing can increase strength by up to 25%.

Another key technique is precision rolling. This method allows for thinner gauges and tighter tolerances, making the final products more versatile. It helps achieve a surface finish that meets industry standards. According to recent industry reports, precision rolling has reduced waste by approximately 15% in various applications. However, this process requires careful control. Over-rolling can lead to defects. Manufacturers need to monitor tension and speed closely.

Surface treatment is also essential. Techniques like galvanizing add a protective layer. This can prevent corrosion in harsh environments. However, not all treatments are equally effective. Some may have limited durability. It's crucial to select the right method based on the intended application. Each processing technique has its pros and cons. Understanding these is vital for optimizing production quality and efficiency.

Cold rolled coils play a crucial role in various manufacturing processes. Adhering to industry standards is essential for quality assurance. According to a recent report by the American Iron and Steel Institute, up to 70% of the cold-rolled steel produced meets or exceeds specified properties. However, many manufacturers struggle with maintaining consistency.

Quality control measures often involve rigorous testing. Techniques such as tensile strength tests, thickness measurements, and surface defect inspection are standard. Industry standards, such as ASTM A1008, guide these practices. But not every manufacturer routinely applies these standards. This inconsistency can lead to product defects and increased costs.

Environmental factors also influence quality. Humidity, temperature, and storage conditions affect the coils' properties. This highlights the need for proper handling and storage to avoid corrosion or deformation. Balancing quality control and efficient production remains a challenge for many in the industry. Reflecting on these aspects is crucial for enhancing manufacturing processes.