Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

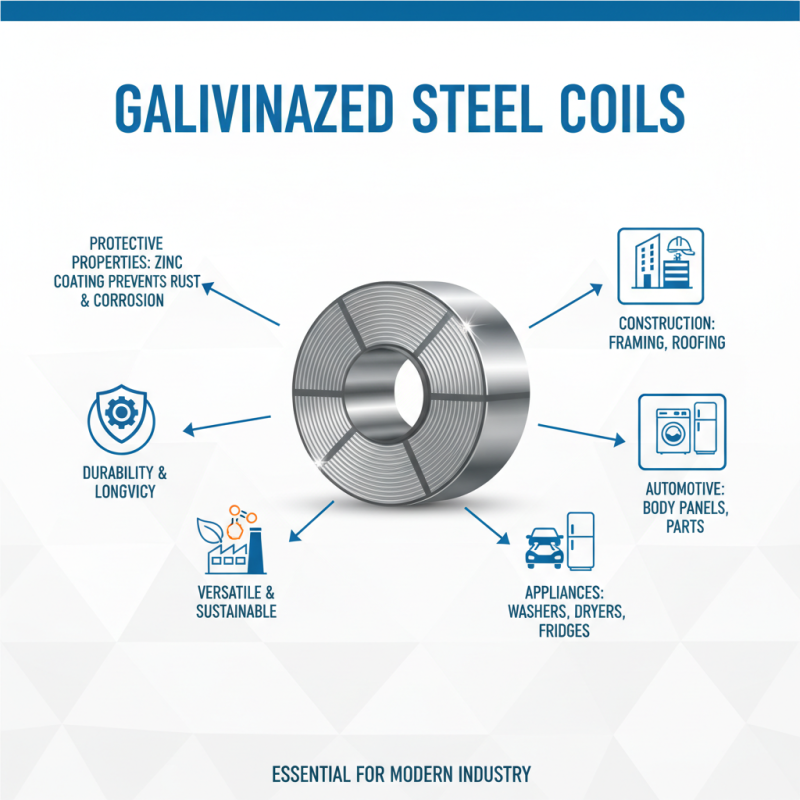

Galvanized coils are increasingly vital in various industries. Their popularity stems from their corrosion resistance and durability. These coils are coated with zinc, enhancing their strength and longevity.

In construction, galvanized coils are widely used for roofing and siding materials. They provide protection against harsh weather conditions. In the automotive sector, these coils serve crucial roles in manufacturing parts like chassis and frames. Their lightweight yet robust nature contributes to vehicle efficiency.

However, industries must consider sourcing practices. Not all galvanized coils are produced in eco-friendly ways. Striking a balance between quality and sustainability is essential. The future of galvanized coils holds potential, yet challenges exist. Understanding these aspects is crucial for making informed decisions.

Galvanized coils are essential in various industrial applications. Their primary characteristic is corrosion resistance. This feature is crucial in industries exposed to harsh environments. Reports indicate that galvanized steel can last up to 50 years, depending on the environment and coating thickness.

Another key characteristic is versatility. Galvanized coils can be employed in construction, automotive, and appliance manufacturing. For instance, the construction sector benefits significantly. In 2023, it was noted that almost 70% of new buildings utilize galvanized materials for frames and roofing. This usage reflects the material's effective protection against rust and wear.

Cost-effectiveness is also a vital trait. Galvanized coils offer reduced maintenance costs over time. However, some industries face challenges. The initial investment may deter smaller companies. Furthermore, not all applications benefit equally from galvanized coils. There are instances where alternative materials may serve better, highlighting the importance of careful selection.

The chart above illustrates the top uses of galvanized coils across various industries in 2026. As shown, the construction industry leads in usage with 25%, followed by automotive at 20%. Other sectors, including electrical and agriculture, also utilize galvanized coils significantly.

In 2026, galvanized coils play a vital role in various industries. Their resistance to corrosion makes them ideal for construction projects. Buildings, bridges, and other structures often utilize galvanized steel. These materials are durable and can withstand harsh weather conditions. Architects frequently choose them to enhance the longevity of their designs.

The automotive industry also heavily relies on galvanized coils. They are used in car frames to prevent rust and extend the vehicle's life. However, not all manufacturers utilize these coils effectively. Some ignore proper coating thickness, risking premature deterioration. Attention to these details is crucial for safety and performance.

In the appliance sector, galvanized coils are common in making durable products. Washing machines and refrigerators benefit from their protective qualities. Still, quality control can sometimes fall short. Weak spots may appear in products due to inadequate galvanization, leading to customer dissatisfaction. Continual improvement is essential in this evolving market. Such issues remind manufacturers to prioritize quality in their production processes.

Galvanized coils serve many industries due to their protective properties. These coils are made by coating steel with zinc, preventing rust and corrosion. They find innovative applications in construction, automotive, and appliances.

In construction, galvanized coils are essential for metal framing and roofing. They provide strength while resisting extreme weather. Many companies overlook the importance of selecting the right thickness for their projects. Incorrect choices can lead to unexpected issues down the line.

The automotive sector uses galvanized coils for body panels, ensuring durability. Yet, not all galvanization processes are equal. Some manufacturers discover that lower-quality coatings wear off faster than expected. It's crucial to understand the difference between various galvanizing methods.

Tip: Always ask about the coating thickness when purchasing galvanized materials. It impacts the longevity of your product. Also, consider environmental factors in your area. They can affect the performance of galvanized coils significantly.

Galvanized coils are essential in various industries, primarily due to their corrosion resistance. According to industry reports, over 70% of steel production features some form of galvanization. This protective layer helps to prevent rust and extends the lifespan of products, especially in harsh environments.

In construction, galvanized coils are highly favored for roofing materials. These coils can withstand extreme weather, from heavy rain to intense sunlight. They offer a cost-effective solution by reducing maintenance needs. Studies show galvanized steel can last over 50 years without significant deterioration. This longevity ultimately leads to reduced costs over time.

Despite their benefits, not all galvanized products are created equal. Variations in coating thickness can affect performance. For instance, a thinner coating may not provide sufficient protection in coastal areas with high salinity. Industry surveys indicate that companies sometimes overlook these details, leading to premature failures. Therefore, understanding the specific requirements for each application is critical for maximizing the advantages of galvanized coils.

Galvanized coils are gaining traction in various industries. The flexibility of this material offers numerous applications. In 2026, we expect its use to evolve significantly. Industries will rely more on galvanized coils for construction and automotive purposes. These coils are favored for their corrosion resistance and durability, essential for long-term projects.

Emerging trends suggest an increasing demand for eco-friendly materials. Companies are looking for sustainable options, and galvanized coils can meet this need. Innovations in coating techniques may reduce environmental impact. However, supply chain challenges may hinder widespread adoption. Industry leaders will need to rethink their strategies to ensure availability.

The reliance on galvanized coils will extend beyond traditional applications. This material could find its way into renewable energy sectors. Solar panels and wind turbines may benefit from these robust coils. Nevertheless, one challenge remains: ensuring quality control throughout production. Addressing this issue will be crucial for manufacturers looking to stay ahead of the competition.