Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

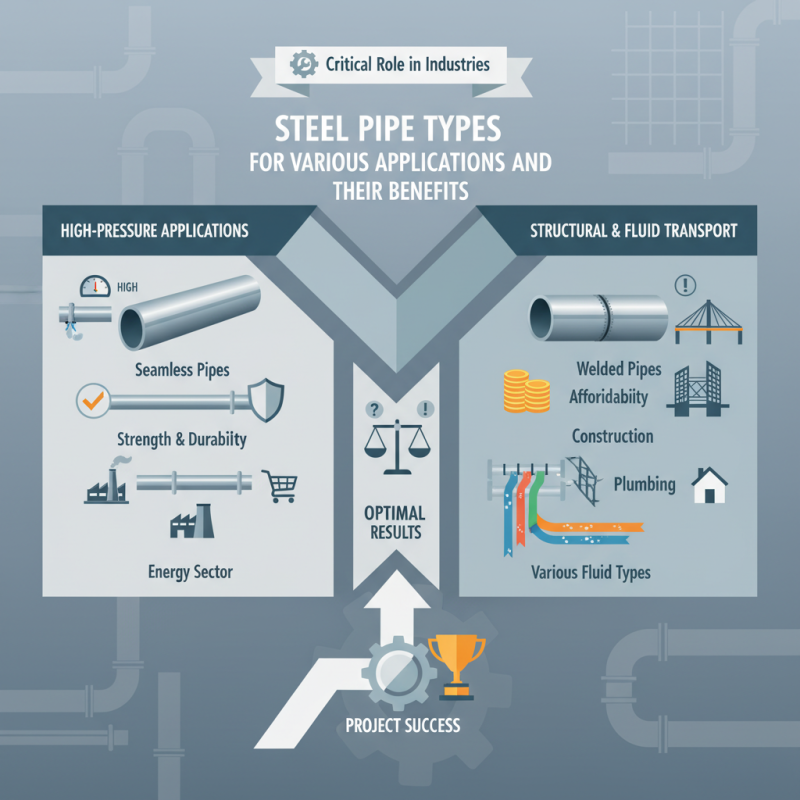

Steel pipe plays a critical role in various industries, from construction to energy. Understanding different types of steel pipes is essential for selecting the right one for your project. Each type has unique characteristics, benefits, and applications.

In many cases, choosing the wrong type can lead to inefficiencies. For example, using a lightweight pipe in a high-pressure system often results in failures. Steel pipes are strong and durable, but their specifications differ significantly. For instance, seamless pipes are ideal for high-pressure applications, while welded pipes are often more affordable.

Exploring the various types also opens doors to multiple applications. Structural applications often require specific grades. On the other hand, plumbing uses different kinds for various fluid types. It’s important to weigh these options carefully. The right steel pipe can make a project successful. Yet, many overlook key details. Understanding these nuances is vital for achieving optimal results.

Steel pipes are crucial in various industries. Their strength and durability make them the go-to choice for construction, plumbing, and gas transport. Different types of steel pipes serve specific purposes, allowing for tailored solutions in projects.

One common type is seamless steel pipes. These pipes have no welded seams, making them ideal for high-pressure applications. They are often used in oil and gas extraction.

Another type is welded steel pipes. These are made by welding two edges together. They are generally less expensive but may not handle high pressure as well as seamless pipes.

Tip: When selecting steel pipes, consider the specific requirements of your project. Factors like pressure ratings and corrosion resistance matter significantly.

Steel pipes also come in various grades. Each grade indicates the material's strength and composition. For instance, low-carbon steel pipes exhibit high ductility, making them easier to work with. However, they may not be as robust as higher-grade materials.

Tip: Always review the standards for the pipes you choose. Not every steel pipe will meet the demands of your application. Doing your due diligence can save headaches down the road.

Steel pipes play a crucial role in various industries. Different types serve specific purposes. For example, seamless steel pipes are widely used in oil and gas applications. They operate under high pressure, making them ideal for transporting liquids. Their lack of seams reduces the risk of leaks.

Welded steel pipes, on the other hand, find utility in structural applications. They are commonly seen in construction projects. Their affordability and availability make them a popular choice. However, they may not perform well under extremely high pressures compared to seamless pipes.

Galvanized steel pipes are used for plumbing and water projects. Their corrosion resistance is beneficial in moist environments. Yet, they may not last as long as pipes made from other materials. It's important to weigh the options based on specific needs. Each type has its strengths and weaknesses, which may lead to revisiting initial choices.

When comparing seamless and welded steel pipes, it’s essential to consider their unique benefits. Seamless pipes, crafted from solid steel, offer excellent strength and durability. They typically have a smoother interior surface, reducing friction. This feature is vital for transporting liquids and gases. Seamless pipes also excel in high-pressure applications. Their ability to withstand stress makes them a popular choice in industries like oil and gas.

On the other hand, welded pipes present their own advantages. They are generally more cost-effective to produce. This affordability makes them accessible for various projects. Welded pipes can be manufactured in larger diameters more easily. They also come in a wide range of lengths. However, welded pipes may have slight imperfections at the seams, which can be a concern. These imperfections can lead to potential weak points, especially in demanding environments.

Both types of pipes serve essential functions in different applications. The choice often depends on project requirements and budget constraints. Understanding these differences can guide you in making the right decision for specific needs. Each type has its pros and cons that deserve careful consideration.

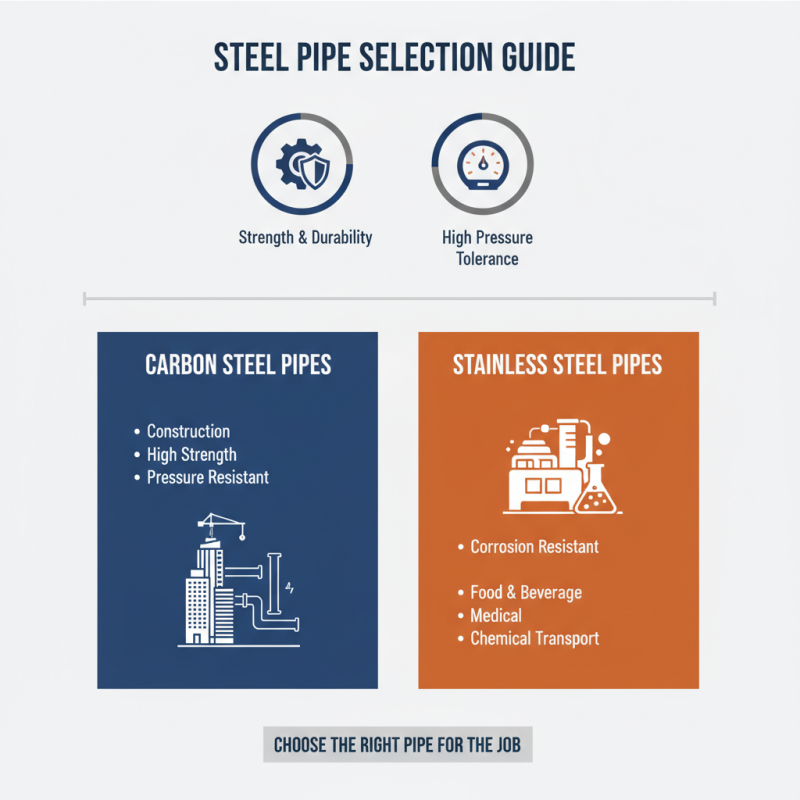

When selecting the right steel pipe material, it’s crucial to consider the application. Each type of steel pipe has unique properties tailored for specific tasks. For instance, carbon steel pipes are often utilized in construction due to their strength and durability. They manage high pressure well, making them suitable for various industrial uses.

On the other hand, stainless steel pipes resist corrosion, making them ideal for plumbing systems. They last longer and can handle extreme temperatures. However, they come at a higher cost. Choosing a material based solely on price can lead to costly repairs later.

**Tip**: Always assess the environment where the pipes will be used. Factors like exposure to chemicals or extreme weather can significantly affect performance.

Remember to evaluate the pressure ratings of pipes before installation. A mismatch can cause failures. Steel pipes need to fit the demands of the job accurately.

**Tip**: Seek expert advice if unsure. A knowledgeable professional can help navigate choices. Think through requirements carefully to avoid mistakes.

The steel pipe manufacturing industry is witnessing significant evolution. Emerging technologies like 3D printing and automation are reshaping production lines. This shift aims to improve efficiency and reduce waste. However, adapting to these innovations can be challenging. Many manufacturers face a steep learning curve.

Sustainability is another key trend. The push for greener solutions is driving the use of recycled materials. This approach not only conserves resources but also lowers carbon footprints. Yet, the balance between recyclability and maintaining quality is often tricky. Companies must continually assess their methods to avoid compromising standards.

Moreover, digitalization is revolutionizing operations. Real-time data analytics help optimize performance and predict maintenance needs. Despite the potential benefits, some manufacturers struggle with data integration. There’s a fear of falling behind, while others remain hesitant to fully embrace technology. The future of steel pipe applications looks promising, but it demands flexibility and a willingness to adapt.