Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Steel Material plays a pivotal role in both construction and manufacturing, underpinning a substantial portion of the global economy. As per the World Steel Association, global crude steel production reached approximately 1.9 billion metric tons in 2021, highlighting its demand and significance across various industries. This versatile material, known for its strength, durability, and recyclability, has become the backbone of modern architecture and infrastructure.

In construction, Steel Material is essential for the structural integrity of buildings, bridges, and other critical infrastructures. Its ability to withstand heavy loads and resist environmental factors makes it indispensable in ensuring safety and longevity. According to a report by Research and Markets, the construction steel market is projected to grow by around 6% annually through 2028, driven by urbanization and infrastructure development.

Moreover, the manufacturing sector relies heavily on Steel Material for producing a wide range of products, from automobiles to appliances. The durability and adaptability of steel make it a preferred choice for manufacturers seeking to balance efficiency with quality. As industries continue to innovate, the role of steel is expected to evolve, further solidifying its importance in shaping a sustainable future in construction and manufacturing.

Steel material is an alloy primarily composed of iron and carbon, which is recognized for its strength, durability, and versatility. The amount of carbon added to iron usually ranges from 0.2% to 2.1%, which significantly enhances the properties of the base metal. This blend allows steel to exhibit remarkable tensile strength while maintaining a relatively low density. Additionally, trace elements such as manganese, chromium, nickel, and vanadium can be included to fine-tune specific characteristics, such as improved corrosion resistance or enhanced hardness, making steel suitable for a wide variety of applications.

In construction and manufacturing, the significance of steel cannot be overstated. Its high strength-to-weight ratio allows for the creation of structures that are both robust and lightweight, facilitating innovative architectural designs. Steel’s malleability enables it to be easily shaped into various forms, while its recyclability contributes to sustainable practices in the industry. Furthermore, steel structures, such as beams and reinforcements, provide essential support and stability in buildings, bridges, and various infrastructure projects. The combination of these attributes positions steel as a critical material driving modern construction and manufacturing processes forward.

| Property | Description |

|---|---|

| Density | 7850 kg/m³ |

| Yield Strength | 250-600 MPa |

| Tensile Strength | 400-1000 MPa |

| Ductility | High, allowing deformation before fracture |

| Composition | Primarily composed of Iron (Fe) and Carbon (C), with other alloys |

| Corrosion Resistance | Varies; stainless steel offers better resistance |

| Applications | Used in construction, automotive, manufacturing, and household products |

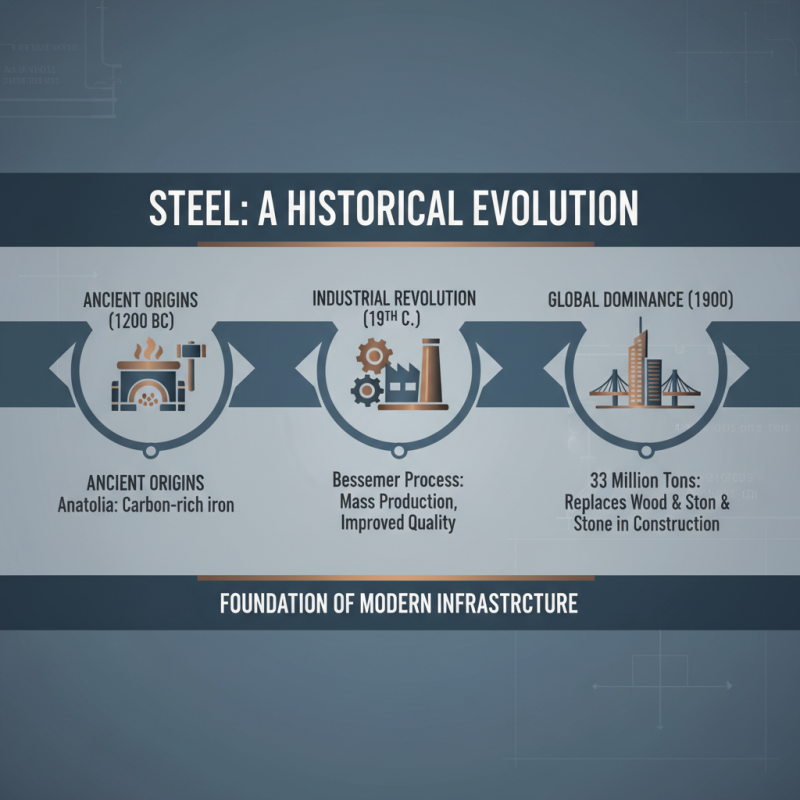

The historical evolution of steel in construction and manufacturing marks a significant turning point for various industries. The origins of steel date back to around 1200 BC in Anatolia, where carbon-rich iron was produced through primitive smelting techniques. Over the centuries, steel's use expanded, particularly during the Industrial Revolution in the 19th century, where advancements in metallurgy and mass production techniques, such as the Bessemer process, revolutionized its availability and quality. By 1900, global steel production reached 33 million tons, demonstrating its burgeoning role in construction, as it began to replace traditional materials like wood and stone in buildings and infrastructure.

In the 20th century, the importance of steel solidified further with its application in skyscrapers, bridges, and other critical infrastructures. The American Institute of Steel Construction reported that, by 2020, steel accounted for nearly 70% of the materials used in new structures in the United States. This trend is not limited to the U.S.; worldwide steel consumption is projected to reach approximately 1.8 billion metric tons annually by 2030, as outlined by the World Steel Association. The versatility, strength, and recyclability of steel have made it the material of choice across the global construction and manufacturing sectors, thus shaping modern architecture and design principles.

Steel is renowned for its remarkable properties that make it a cornerstone in construction and manufacturing industries. One of its most significant attributes is strength. Steel possesses a high tensile strength, enabling it to withstand heavy loads and stresses without deformation. This characteristic is particularly crucial in structural applications, where safety and stability are paramount. The ability of steel to bear massive weights makes it the preferred material for building frameworks, bridges, and other infrastructures that require uncompromising strength.

Durability is another key property of steel, contributing to its longstanding dominance in various applications. Steel's resistance to wear, corrosion, and environmental factors allows structures to maintain their integrity over time. This longevity not only reduces the need for frequent replacements but also minimizes maintenance costs. Additionally, advancements in protective coatings and treatments have further enhanced steel's longevity, making it suitable for use in diverse settings, from coastal regions to industrial environments.

Versatility is perhaps the most compelling aspect of steel. It can be easily molded, welded, and fabricated into myriad forms, which opens up endless possibilities in design and functionality. This adaptability allows engineers and architects to bring innovative concepts to life, ranging from high-rise buildings to complex machinery components. The combination of strength, durability, and versatility positions steel as an indispensable material in modern construction and manufacturing, supporting a wide array of applications across different sectors.

Global steel production has seen significant fluctuations over the years, influenced by various economic and industrial factors. As of recent statistics, the overall output of steel worldwide has indicated a gradual recovery following the downturns experienced during economic recessions. The rise in infrastructure projects, especially in emerging economies, has driven demand for steel, making it a cornerstone material in construction and manufacturing sectors. In 2023, projections suggested that global steel production would continue to increase, reflecting an uptick in construction activities and industrial manufacturing.

The implications of these trends are profound for the steel industry. As production ramps up, countries must focus on sustainable practices to minimize environmental impact. Steel manufacturing is energy-intensive, and with the growing concerns over carbon emissions, there is a push towards adopting greener technologies and processes. Additionally, the fluctuating demand influences market dynamics, leading to adjustments in pricing and trade policies. Understanding these trends not only helps stakeholders to make informed decisions but also paves the way for innovations that could redefine how steel is produced and utilized in the future.

Steel is a fundamental material in both construction and manufacturing, credited for its versatility and strength. In modern construction, steel is used widely in the framing of buildings, bridges, and other infrastructural projects. According to the World Steel Association, steel accounts for approximately 50% of the weight of a typical building, making it essential for structural integrity and safety. Its ability to withstand extreme loads, including those from natural disasters, reinforces its role in developing resilient infrastructures. The global construction industry is set to consume over 1.6 billion tons of steel in the next few years, emphasizing the material’s ongoing relevance as urbanization accelerates worldwide.

In the manufacturing sector, steel plays a crucial role in the production of a myriad of products, from automobiles to machinery. Reports indicate that the automotive industry alone is one of the largest consumers of steel, utilizing around 22% of total steel output. This demand stems from steel's favorable properties such as high strength-to-weight ratios and corrosion resistance. Furthermore, advancements in steel processing technology, including hot stamping and advanced high-strength steels, enable manufacturers to produce lighter and more fuel-efficient vehicles while ensuring safety standards are met. As industries strive for sustainability, the recyclability of steel also positions it as a key material in circular economies, further underlining its importance in the modern manufacturing landscape.