Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Prepainted Corrugated Steel Sheet is a versatile building material. Its vibrant color and durable coating make it a popular choice. Many industries utilize this product for various applications, including roofing and siding.

This material combines aesthetic appeal with practical benefits. It is lightweight yet strong, able to withstand harsh weather conditions. The layered paint finish offers protection against rust, which extends its lifespan. However, not all coatings are equal. Different grades may affect durability over time.

In today’s construction industry, sustainability is key. Prepainted Corrugated Steel Sheet often contains recycled materials. This aspect appeals to eco-conscious consumers. However, some may question its environmental impact during production. Adjustments may be needed to enhance its green credentials. Thus, the ongoing conversation around its use continues to evolve.

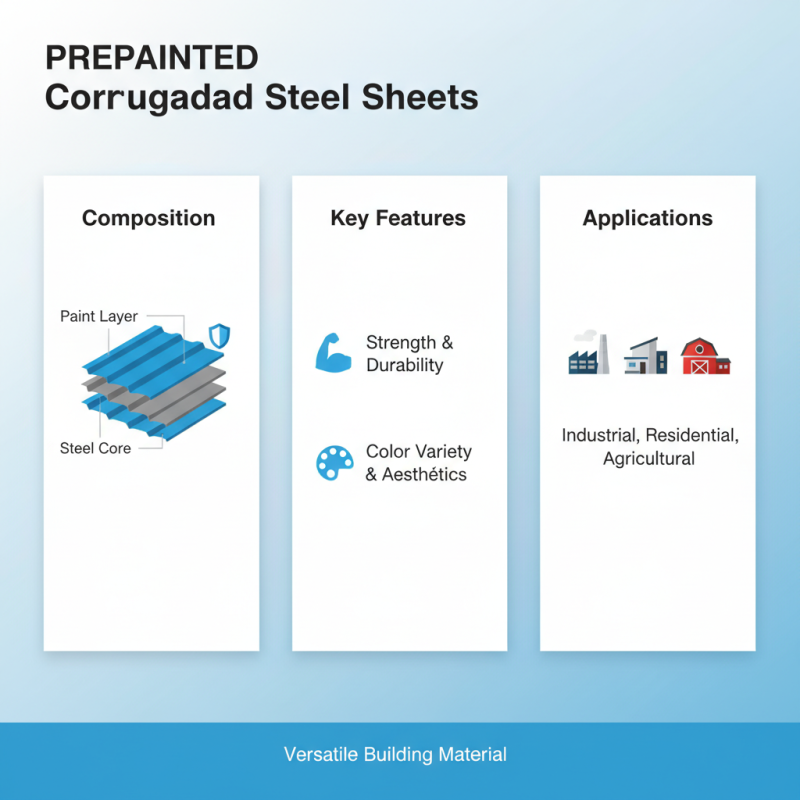

Prepainted corrugated steel sheets are versatile building materials. They consist of a core metal layer, typically steel, coated with a protective paint layer. The combination gives them strength and durability. The coating can be in various colors, allowing for aesthetic flexibility. This feature makes them appealing for various architectural applications.

The composition includes zinc or aluminum, which enhances corrosion resistance. The paint used is often polymer-based, providing longevity and resilience against harsh weather. The sheets are produced in several thicknesses and profiles, catering to different needs. They can be shaped easily, making installation efficient.

However, their benefits come with considerations. The environmental impact of production processes is worth examining. Not all prepainted sheets offer the same level of quality. Buyers should remain vigilant and seek reliable sources. This choice is crucial for long-term use and sustainability.

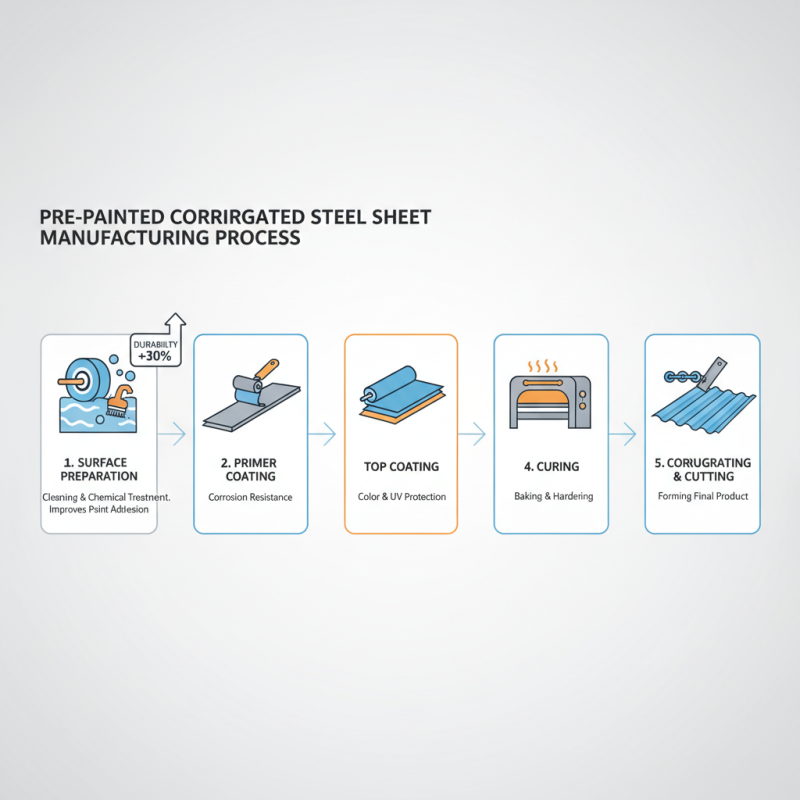

The manufacturing process of prepainted corrugated steel sheets involves several key steps. First, a base steel sheet undergoes surface preparation. This includes cleaning and chemical treatment to enhance paint adhesion. A study indicates that proper surface preparation can improve paint durability by over 30%.

Next, a primer coat is applied. This is essential for corrosion resistance and longevity. Once cured, a topcoat follows. The choice of color and finish can impact heat absorption and aesthetic appeal. According to industry reports, the color selection can affect the thermal efficiency of buildings. Dark colors absorb more heat, whereas lighter shades reflect it.

After painting, the sheets are shaped into corrugated forms. This enhances strength while reducing material usage. However, the corrugation process can sometimes introduce stress points. These areas may require additional inspection. On occasion, paint defects can occur, prompting the need for reevaluation. Manufacturers must continuously optimize processes to ensure quality and efficiency.

Prepainted corrugated steel sheets are a popular choice in construction. They offer numerous benefits for various applications. These sheets come in vibrant colors and can mimic other materials. This ensures aesthetic appeal for any project.

One major benefit of using prepainted corrugated steel is its durability. These sheets are resistant to rust and corrosion. This makes them ideal for outdoor use. The paint coating provides an extra layer of protection. However, not all coatings are the same. Some may wear off faster than expected. Always check specifications when choosing your materials.

Another key advantage is low maintenance. Once installed, they require minimal upkeep. Cleaning them occasionally keeps their appearance fresh. However, some may neglect this, leading to unnecessary wear. Regular inspections can prevent long-term issues.

**Tip:** When selecting colors, consider the environment. Lighter colors reflect sunlight, reducing heat absorption. This can lower cooling costs in buildings.

In conclusion, prepainted corrugated steel sheets provide both practicality and style. Consider their benefits for your next project, and take care to maintain their longevity.

| Benefit | Description | Application | Durability |

|---|---|---|---|

| Corrosion Resistance | Prepainted corrugated steel sheets have a protective coating that prevents rust and corrosion. | Roofing and wall cladding in coastal areas. | Long-lasting performance even in harsh environments. |

| Aesthetic Appeal | Available in various colors and finishes to enhance the visual appeal of structures. | Commercial and residential buildings. | Retains color and finish for many years. |

| Lightweight | Easier to handle and install compared to traditional materials. | Quick construction projects and renovations. | Less stress on structural supports. |

| Sustainability | Made from recyclable materials and can be recycled at the end of their life cycle. | Green building projects. | Reduces environmental impact. |

| Cost-Effective | Lower installation and maintenance costs over time. | Industrial and agricultural buildings. | High return on investment. |

Prepainted corrugated steel sheets have numerous applications across various industries. They are prominently used in building construction, roofing, and manufacturing. A report from the Global Steel Research Institute indicates that the demand for such materials is expanding. The resilient nature of these sheets makes them ideal for outdoor environments. They withstand harsh weather and resist corrosion. This quality ensures longevity, reducing the need for frequent replacements.

In the agricultural sector, prepainted corrugated steel sheets are favored for storage facilities and barns. Their lightweight design allows for easy installation and transportation. They contribute to energy efficiency, reflecting sunlight to keep interiors cool. Additionally, the aesthetic options available not only serve functional purposes but also enhance the overall appearance of structures. According to recent findings, around 40% of construction projects now opt for these materials, showcasing their rising popularity.

However, industries should remain vigilant about the sourcing of raw materials. Over-reliance on a single supplier can lead to shortages. Furthermore, while the initial cost of prepainted sheets might be higher, the long-term savings from durability should be weighed carefully. Balancing these factors is essential for making informed choices in construction and manufacturing.

Prepainted corrugated steel sheets offer unique advantages over traditional steel sheets. A key difference lies in their manufacturing process. Prepainted sheets receive a layer of paint prior to forming. This protects the steel from rust and enhances durability. Traditional sheets, on the other hand, require post-coating, which can leave them vulnerable to corrosion during the initial stages of installation.

Industry reports show that the global market for prepainted steel is expected to grow significantly. As of 2022, the prepainted steel market valued over $30 billion. Its demand has risen by 8% annually. This growth highlights the increasing preference for prepainted products among consumers.

Despite these advantages, some concerns exist. Prepainted sheets may cost more upfront. The initial investment can deter some buyers. Moreover, in extreme weather conditions, paint may chip or fade, reducing aesthetic appeal. Understanding these drawbacks is crucial. Balancing initial costs against long-term benefits is essential for decision-makers.