Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Pp Corrugated Steel Sheet is crucial for various construction projects. This product has gained traction due to its lightweight, durability, and versatility. According to the latest industry report by Smith and Associates, the global market for corrugated steel sheets is projected to grow by 4.5% annually. This growth highlights the rising demand for effective roofing and wall solutions.

When selecting Pp Corrugated Steel Sheets, consider material thickness and coating type. Thicker sheets provide better durability, while different coatings protect against corrosion. A recent study indicated that up to 40% of users reported issues with sheet performance due to improper selection. The decision may seem simple, but the details matter significantly.

It's important to reflect on the specific needs of your project. A mismatch between the sheet type and application can lead to costly repairs or inefficient insulation. Making an informed choice will pay off in the long run. Attention to detail in choosing the right Pp Corrugated Steel Sheet can prevent future headaches.

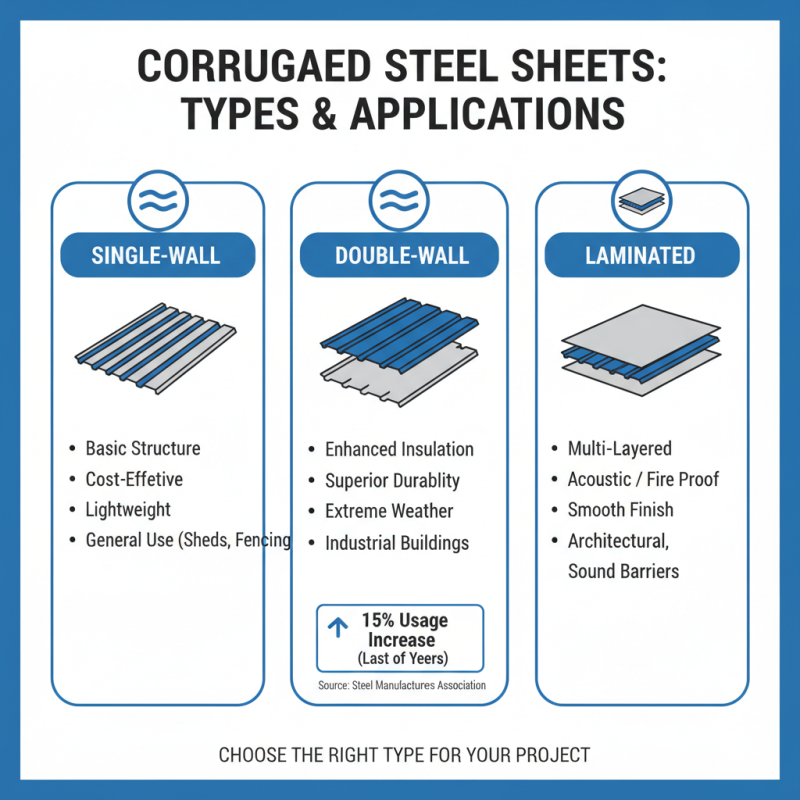

When considering pp corrugated steel sheets, it's vital to understand the various types available. Broadly, these sheets fall into three categories: single wall, double wall, and laminated sheets. Each type offers distinct benefits and drawbacks, influencing their performance in different applications. For instance, double wall sheets possess superior insulation properties and better durability, making them suited for extreme weather conditions. A report from the Steel Manufacturers Association indicates that double-wall options are gaining traction, increasing by approximately 15% in usage over the past five years.

However, choosing a type often involves compromise. While single wall sheets are lighter and more cost-effective, they lack the strength and resistance offered by double wall or laminated varieties. Additionally, laminated sheets, while excellent for moisture resistance, can be pricier and heavier. The International Steel Study notes that nearly 27% of projects reported issues related to sheet choice, emphasizing the importance of clarity on project requirements before purchasing.

Your specific needs should guide your selection process. Consider factors like weight, insulation needs, and structural requirements. Simple analysis can reveal the right choice. Still, many underestimate the consequences of making an uninformed selection. This oversight can lead to additional costs or structural failures down the line. Balancing budget with performance specifics is essential for ensuring a successful material choice.

When choosing PP corrugated steel sheets, there are key factors to consider. One important aspect is the sheet thickness.

Thicker sheets offer better durability against harsh weather. However, they can be heavier, making installation more challenging.

It’s crucial to balance these qualities based on your specific needs.

Another factor is the sheet color. Lighter colors can reflect heat, keeping your space cooler. Darker hues may absorb heat, which could be undesirable in hot climates.

Think about your location’s weather patterns when making this choice.

Tips:

Check for quality certifications. This ensures the product meets required standards. Additionally, consider the lifespan of the sheets. Some may corrode faster than others.

It’s valuable to research and compare options. Remember to weigh aesthetics against functionality.

You want a product that looks good but also lasts.

When selecting corrugated steel sheets, durability and strength become essential factors. Durability is often measured by the coating type. A study by the Steel Construction Institute indicates that galvanized steel displays excellent corrosion resistance. This can lead to an average lifespan increase of 20-30% compared to uncoated options. On the contrary, some alternatives like polymer-coated sheets offer aesthetic advantages but may not hold up as well in harsh conditions.

The strength of steel sheets also varies significantly. Data from the American Iron and Steel Institute shows that high-strength low-alloy (HSLA) steel can provide up to 30% more tensile strength than regular mild steel. This higher strength translates to better performance in weight-bearing applications. However, many people overlook this while prioritizing cost over performance. A clever choice depends on environments where the sheets will be installed. In coastal areas, for instance, the specific exposure to salty air can accelerate deterioration in less durable options.

Understanding these aspects can avoid unforeseen issues. Durability is not solely about the materials used but also about the application. Real-world experience often reveals that overestimating the longevity of cheaper options results in higher long-term costs. Thus, evaluating both strength and durability against environmental factors ensures more informed decisions. These reflections can guide potential buyers in matching their needs to the right corrugated steel sheet.

When budgeting for PP corrugated steel sheet projects, it’s essential to assess all costs carefully. Materials, labor, and transportation make up the bulk of expenses. Think about where you’ll source your sheets. Local suppliers may reduce shipping costs. However, quality varies. Sometimes, cheaper isn’t better. Inspect samples before committing.

Labor costs can also fluctuate significantly. Hiring skilled workers might raise your budget. Yet, untrained labor can lead to mistakes. Think about any potential delays. Extra costs may arise from rework. Maintenance is another factor to consider. Corrosion prevention can add to your long-term expenses. It is crucial to evaluate if you’ll need additional treatments for durability.

Misjudging your budget can lead to frustration. Some projects exceed initial estimates. Keeping a buffer for unforeseen costs is wise. Always review and adjust your budget based on real-time findings. Monitor ongoing expenses. Requesting quotes from multiple suppliers can also provide a clearer picture. Balancing cost and quality is paramount.

When it comes to maintaining Pp corrugated steel sheets, proper care is crucial for longevity. These sheets are known for their durability, but they can be susceptible to corrosion if not maintained correctly. A study from the Steel Construction Institute indicates that regular checks and appropriate treatments can extend their lifespan by up to 30%.

One essential tip is to keep the sheets clean. Dust and debris can trap moisture, accelerating corrosion. Use a soft brush or gentle water spray to remove build-up. Avoid harsh chemicals that can damage the protective coating. Another important aspect is to inspect the sheets for any signs of damage. Look for scratches or dents. Even minor damages can lead to bigger issues if not addressed timely.

Moreover, applying a protective coating can greatly enhance durability. This can help seal minor imperfections. However, remember that not all coatings are suitable. Some can diminish the sheet's original properties. It’s worth researching or consulting with professionals for the right products. Regular maintenance checks can mean the difference between replacement and a lasting investment.

| Dimension | Material Type | Thickness (mm) | Coating Type | Weight (kg/m²) | Expected Lifespan (Years) |

|---|---|---|---|---|---|

| 2 x 1 m | PP Coated Steel | 0.5 | Zinc Coating | 6.5 | 15 |

| 3 x 1 m | PP Coated Steel | 0.7 | Polyester Coating | 8.0 | 20 |

| 2.5 x 1 m | PP Coated Steel | 0.6 | High Gloss Coating | 7.2 | 18 |

| 1.5 x 1 m | PP Coated Steel | 0.4 | Matt Coating | 5.5 | 12 |