Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the versatility and strength of Cr Steel Sheet have made it a vital component across various industries, ranging from automotive to construction. As industries strive for innovation and efficiency, the demand for advanced materials that offer durability, corrosion resistance, and lightweight features has surged. Cr Steel Sheets, with their exceptional performance characteristics, are paving the way for groundbreaking applications that meet the evolving challenges of modern manufacturing. This blog will explore innovative solutions that leverage the unique properties of Cr Steel Sheet, highlighting its role in enhancing productivity and sustainability. By delving into the future of Cr Steel Sheet applications, we aim to provide insights into how this remarkable material is shaping the landscape of multiple sectors and driving technological advancements.

Cr steel sheets, known for their remarkable strength and corrosion resistance, have become essential in the automotive manufacturing industry. These materials play a crucial role in ensuring that vehicles are not only lightweight but also durable and safe. The application of Cr steel sheets allows manufacturers to develop components that can withstand the rigors of daily use while maintaining structural integrity. For instance, Cr steel is often used in the production of body panels, chassis, and other vital components where performance and resilience are non-negotiable.

Moreover, as the automotive sector pivots towards sustainability, Cr steel sheets are proving to be a game-changer. Their recyclability aligns perfectly with the industry's increasing focus on reducing environmental impact. Automakers are adopting innovative design practices that leverage the properties of Cr steel to enhance fuel efficiency through weight reduction without compromising safety standards. This trend not only supports environmental goals but also meets consumer demands for more efficient and eco-friendly vehicles, setting a new standard in automotive manufacturing.

This chart illustrates the cutting-edge uses of Cr steel sheets across different sectors, highlighting their application in automotive manufacturing, construction, electronics, and appliance industries.

The construction industry has witnessed a transformative shift with the integration of chromium (Cr) steel sheets, which have become vital in infrastructure projects. These sheets provide enhanced strength, durability, and corrosion resistance, essential for innovative construction solutions. According to a recent industry report, the demand for Cr steel sheets in construction is projected to grow by 7.5% annually through 2025, driven by increased urbanization and the need for sustainable building materials.

One of the most compelling advantages of Cr steel sheets is their ability to withstand harsh environmental conditions. For instance, in coastal areas where humidity and salt exposure are prevalent, Cr steel sheets significantly extend the lifespan of structures. A study by a leading materials research organization indicated that buildings utilizing Cr steel sheets can exhibit up to 50% longer life spans, minimizing maintenance costs and contributing to overall project sustainability. By revolutionizing materials used in construction, Cr steel sheets play a crucial role in modern infrastructure development, prioritizing both safety and longevity.

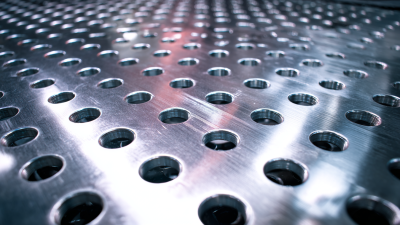

In the rapidly evolving world of electronics, the integration of chromium (Cr) steel sheets is revolutionizing the design and functionality of high-tech devices. These advanced materials boast exceptional properties such as corrosion resistance, durability, and superior strength, making them ideal for use in various electronic components. From smartphones to sophisticated medical equipment, Cr steel sheets are increasingly being utilized to enhance performance and extend the lifespan of devices, ensuring that they meet the growing demands of consumers and industries alike.

One of the most significant applications of Cr steel sheets is in the fabrication of components that require a lightweight yet robust structure. For instance, in the production of portable electronic devices, Cr steel sheets provide the necessary structural integrity while minimizing weight. Additionally, their excellent thermal conductivity makes them suitable for heat dissipation applications in high-performance electronics, preventing overheating and ensuring efficient operation. By incorporating Cr steel sheets into their designs, manufacturers can create more reliable and efficient high-tech devices, paving the way for the next generation of electronics.

In recent years, the industrial sector has shifted towards adopting sustainable practices, and CR (Cold Rolled) steel sheets have emerged as a key player in this transition. These eco-friendly innovations are gaining traction across various industries, including automotive, construction, and renewable energy. By using CR steel sheets, manufacturers can significantly reduce material waste and energy consumption during production. The lightweight and highly durable nature of these sheets makes them an ideal choice for applications where efficiency and sustainability are paramount.

Moreover, the recyclability of CR steel sheets reinforces their standing as an eco-friendly material. Industries are increasingly focusing on life-cycle assessments and incorporating recycled steel into their products, which not only conserves resources but also minimizes the carbon footprint associated with steel production. This sustainable approach not only helps companies comply with stringent environmental regulations but also meets the growing consumer demand for greener products. As industries continue to prioritize eco-consciousness, CR steel sheets represent a forward-thinking solution that aligns innovation with sustainability.

Cr steel sheets are gaining significant traction across various sectors due to their unique properties and versatility. Recent advancements in Cr steel sheet technologies are transforming applications in automotive, construction, and energy industries. The integration of high-performance materials is allowing for lighter, more resilient structures, which is crucial as industries prioritize sustainability and efficiency. The innovative approaches in manufacturing methods, including advanced welding and coating techniques, are enhancing the durability and performance of these sheets, making them ideal for demanding environments.

Looking ahead, the future trends in Cr steel sheets will likely focus on increased automation in production processes and the development of alloy compositions that optimize both strength and weight. Research and technological advancements are paving the way for more eco-friendly production methods, which aligns with the growing global emphasis on reducing carbon footprints. As industries evolve, the demand for high-quality, advanced Cr steel sheets will spur further innovation, offering exciting opportunities for enhanced performance and sustainability in engineering applications.