Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the demand for Cr steel sheets has surged, driven by their remarkable strength, durability, and corrosion resistance. According to a market analysis report by Steel Research Institute, the global market for Cr steel sheets is expected to grow at a CAGR of 5.2% from 2023 to 2030, indicating a substantial increase in applications across various industries. With the automotive, construction, and manufacturing sectors leading this expansion, understanding the benefits and types of Cr steel sheets becomes critical for stakeholders.

Expert in the field, Dr. Emily Carter, notes, “The versatility of Cr steel sheets makes them a preferred choice for many industrial applications, as they not only enhance structural integrity but also contribute to overall efficiency and sustainability.” This statement underscores the importance of Cr steel sheets in adapting to the evolving demands of modern manufacturing processes. As industries gravitate toward materials that offer both performance and environmental benefits, Cr steel sheets stand out for their unique qualities, making them a vital component in engineering solutions today.

As we delve deeper into this ultimate guide, we will explore the diverse applications, the significant advantages offered by Cr steel sheets, and the various types available in the market. This comprehensive overview will equip readers with essential insights to make informed decisions in leveraging Cr steel sheets for their projects.

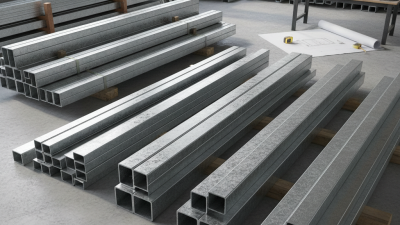

Chrome steel sheets are known for their unique composition and properties, which make them suitable for a wide range of applications. Primarily composed of iron, carbon, and chromium, these sheets benefit from an increased resistance to corrosion and wear. The addition of chromium enhances the steel's hardness and strength, allowing manufacturers to produce materials that can withstand harsh environmental conditions. This combination not only improves durability but also extends the lifespan of products made from chrome steel sheets.

The properties of chrome steel sheets are particularly appealing in various industrial applications. They exhibit excellent resistance to oxidation and temperature fluctuations, making them ideal for use in automotive, aerospace, and construction industries. Moreover, chrome steel sheets have a smooth finish and superior aesthetic appeal, which is advantageous for architectural applications. Their ability to maintain structural integrity under stress contributes to their utility in heavy-duty settings, ensuring reliability in critical components. Overall, understanding the composition and properties of chrome steel sheets is essential for leveraging their benefits in various manufacturing processes.

Cr steel sheets, known for their exceptional strength and corrosion resistance, find a myriad of applications across diverse industries. In the automotive sector, these sheets are widely used for manufacturing body panels and structural components. Their lightweight yet robust nature helps in enhancing fuel efficiency and overall vehicle performance. Furthermore, the inherent resistance to oxidation ensures that vehicles remain aesthetically appealing and maintain structural integrity over time.

In the construction industry, Cr steel sheets serve as a crucial material in the fabrication of steel frames and roofing systems. Their durability and ability to withstand harsh environmental conditions make them ideal for both residential and commercial buildings. Additionally, these sheets are often employed in the production of appliances and machinery, where they provide long-lasting performance and reliability. The versatility of Cr steel sheets allows them to be tailored for specific applications, driving innovation and efficiency in various sectors.

Cr steel sheets have become an essential material in construction and manufacturing due to their unique properties and versatility. One of the primary benefits of using Cr steel sheets is their exceptional corrosion resistance. This property ensures longevity, reducing the need for frequent replacements and maintenance. Additionally, Cr steel sheets offer enhanced strength, making them ideal for structural components that require durability under heavy loads.

Another significant advantage of Cr steel sheets is their ease of fabrication. These sheets can be shaped, cut, and welded with relative ease, facilitating efficient construction processes. In manufacturing, this versatility allows for the production of various components without compromising the material's integrity. Furthermore, Cr steel sheets can be treated in different ways to improve characteristics like hardness and flexibility, making them suitable for diverse applications.

**Tips:** When selecting Cr steel sheets for your projects, consider the specific requirements of your application, such as load-bearing capacity and environmental exposure. It's also important to evaluate the thickness and finish of the sheets to ensure optimal performance. Collaborating with knowledgeable suppliers can provide you with insights into the best options for your needs, helping you make informed decisions.

When it comes to chromium (Cr) steel sheets, understanding the different types and their unique characteristics is essential for making informed decisions in various applications. Chromium steel sheets can typically be classified into several categories based on their alloy composition, which impacts their mechanical properties and resistance to corrosion. Among the most common types are low-chromium (up to 4% Cr) sheets, which offer enhanced hardness and wear resistance, making them suitable for use in automotive components and machinery parts.

Medium-chromium (4% to 12% Cr) sheets are known for their durability and ability to withstand higher temperatures, making them ideal for applications in the energy sector, such as in boilers and turbines. On the other hand, high-chromium sheets (above 12% Cr) are specially designed for extreme environments, offering superior oxidation resistance and are primarily utilized in chemical processing and aerospace industries.

Tip: When selecting a chromium steel sheet, consider the specific environmental conditions it will face, including temperature and exposure to corrosive substances, to ensure it meets your application needs effectively.

In addition to understanding the types, it's crucial to recognize the characteristics of each chromium steel sheet to optimize performance. Features such as tensile strength, hardness, and ductility vary across different types and can influence their suitability for diverse applications. By evaluating these characteristics, industries can choose the right chromium steel sheet to enhance their operational efficiency and longevity of their products.

Tip: Always consult technical specifications and expert recommendations when choosing a chromium steel sheet to ensure it aligns with your operational requirements and enhances product performance.

When comparing Cr steel sheets with other steel materials, the unique properties of chromium play a pivotal role in determining their effectiveness across various applications. Chromium enhances corrosion resistance, hardens the steel, and improves overall durability. According to a recent report by the International Stainless Steel Forum, Cr steel sheets exhibit a corrosion resistance that is up to three times greater than that of standard carbon steel sheets, making them particularly suitable for environments prone to rust and degradation.

Moreover, Cr steel sheets demonstrate superior mechanical properties, with a tensile strength that can exceed that of typical mild steels. Data from the American Iron and Steel Institute indicates that the tensile strength of Cr steel can range from 400 to 750 MPa, depending on the specific alloy and treatment, whereas conventional carbon steels generally have a tensile strength limit of around 250 MPa. This enhanced strength allows Cr steel sheets to be utilized in demanding applications such as automotive parts, construction materials, and industrial equipment, where high performance and longevity are critical.

In addition to their strength and corrosion resistance, Cr steel sheets display remarkable versatility compared to other materials. While materials like carbon and stainless steel have specific applications they excel in, Cr steel sheets can be tailored for a variety of uses, from building facades to heavy machinery. The World Steel Association report cites that an increasing number of manufacturers are adopting Cr steel sheets due to their adaptability, potentially reducing material waste and enhancing production efficiency in the long run. This flexibility positions Cr steel as a compelling choice in the ever-evolving landscape of materials engineering.

| Steel Type | Applications | Benefits | Cost ($/ton) | Corrosion Resistance |

|---|---|---|---|---|

| Cr Steel Sheet | Automotive, Construction | High Strength, Ductility | 800 | Excellent |

| Mild Steel | General Fabrication, Pipes | Cost-Effective, Easily Welded | 700 | Moderate |

| Stainless Steel | Food Processing, Medical Equipment | Superior Corrosion Resistance, Hygiene | 3000 | Excellent |

| Galvanized Steel | Roofing, Fencing | Rust Protection, Versatile | 750 | Good |