Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Gi Pipe, short for galvanized iron pipe, is a popular choice in construction. Its protective zinc coating makes it resistant to rust and corrosion. This quality is essential for durability, especially in humid or wet environments. Builders appreciate Gi Pipe for both its strength and affordability.

The applications of Gi Pipe are varied. It is commonly used in plumbing systems, water supply lines, and for structural support. However, not all situations suit Gi Pipe. For instance, in highly acidic soils, it may deteriorate faster than expected. This requires careful planning and consideration.

Moreover, while Gi Pipe is generally reliable, it does have limitations. It is heavier than other materials, impacting installation. Additionally, improper usage can lead to leaks and failures. Construction professionals must reflect on these aspects. They should weigh the pros and cons before making a choice for their projects. Ultimately, Gi Pipe remains a vital component in modern construction, but thoughtful application is crucial.

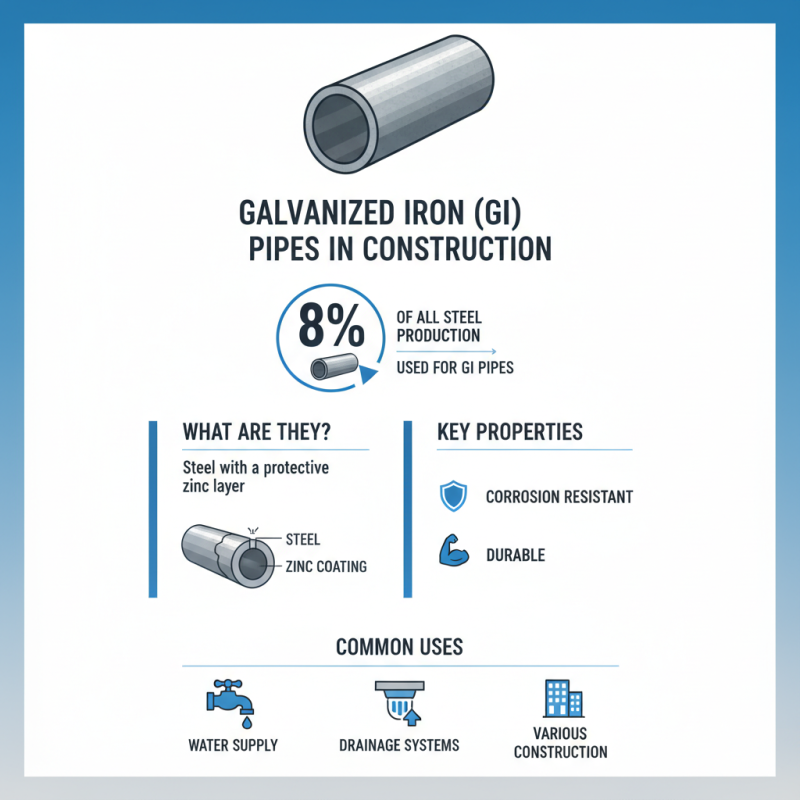

Galvanized Iron (GI) pipes play a crucial role in construction. Made from steel with a protective zinc layer, GI pipes resist corrosion. Their durability makes them suitable for various applications, including water supply and drainage systems. According to industry reports, about 8% of all steel production goes into these pipes, highlighting their significance.

GI pipes are lightweight and easy to handle. This factor adds to their appeal for construction projects. They can be used in residential buildings and commercial complexes alike. A study shows that a well-maintained GI piping system can last over 50 years. However, improper installation or lack of maintenance can lead to premature failures. Not all contractors focus on quality, which can be concerning.

In terms of thermal and electrical conductivity, GI pipes offer good performance. They can withstand high temperatures, making them suitable for hot water applications. Yet, the presence of zinc can lead to galvanic corrosion when paired with other metals. This is why understanding the material's properties is vital. It can prevent costly repairs down the line, owing to a lack of knowledge about proper usage. Such oversights compromise the integrity of the piping system.

GI pipes, or Galvanized Iron pipes, are widely used in construction. The manufacturing process of these pipes is quite detailed. It begins with raw materials, primarily iron and a zinc coating. The iron is melted and then formed into tubes.

Once the tubes are shaped, they undergo a galvanization process. This involves coating them with molten zinc to prevent rust. However, controlling the thickness of the zinc layer is crucial. Too thick or too thin can lead to issues. The tubes must then be cooled properly. Incorrect cooling can warp the pipes.

After cooling, the pipes are cut to specific lengths. Quality checks are essential at this stage. Bubbles or weak spots can compromise their strength. Once approved, the pipes are ready for packaging. It's vital to ensure they are well-protected during transportation. Overlooking minor details can lead to losses later on. Each step must be carefully monitored for quality assurance.

GI pipes, or galvanized iron pipes, are vital in construction. Their durability makes them a preferred choice. These pipes can withstand heavy loads and extreme weather. This strength is critical for structural applications. In many buildings, they support water supply and drainage systems. They have proven to be reliable over time.

Corrosion resistance is another key characteristic. GI pipes undergo a galvanization process. This process coats the iron with zinc, preventing rust. However, the zinc layer can wear off over time. In corrosive environments, like coastal areas, this wear happens faster. It is a point worth considering for long-term projects. Regular inspections can be necessary to maintain integrity.

Strength is essential for construction, yet not all projects use GI pipes effectively. In some cases, lighter materials may be chosen, impacting durability. It’s crucial to match the right material to the project’s needs. Understanding the environment and load requirements is vital. Making the right choices can lead to cost-effective and safe construction.

GI pipes, or galvanised iron pipes, are widely used in construction and infrastructure projects. They are known for their durability and resistance to corrosion. This makes them suitable for various applications. One common use is in plumbing systems. GI pipes can efficiently transport water and gas. Their ability to withstand high pressure is advantageous in residential and commercial buildings.

In addition to plumbing, GI pipes are used for structural purposes. They are essential in creating frames for buildings and bridges. Their strength supports heavy loads. However, some installations may face issues like rust over time. Proper maintenance is crucial to prolong the pipe's life. Regular inspections can help catch problems early.

Furthermore, GI pipes play a role in electrical conduit systems. They protect electrical wiring from external damage. In harsh environments, this is particularly important. Nonetheless, improper installation can lead to safety hazards. Planning and training for workers are vital in avoiding mistakes. These considerations ensure that GI pipes function effectively in various applications.

| Application | Description | Advantages |

|---|---|---|

| Water Supply Systems | GI pipes are commonly used to transport drinking water from treatment facilities to homes and commercial spaces. | Corrosion-resistant, cost-effective, and easy to install. |

| Drainage Systems | Used in sewer and drainage systems to ensure efficient water flow and prevent blockages. | Durable and able to withstand harsh conditions. |

| Structural Frameworks | Utilized in building frameworks and support structures due to their strength. | High tensile strength and lightweight. |

| Electrical Conduits | Used to protect electrical wiring and cables from damage. | Provides safety and durability against environmental factors. |

| Agricultural Use | Employed in irrigation systems to distribute water effectively across farming lands. | Lightweight for easy transport and installation. |

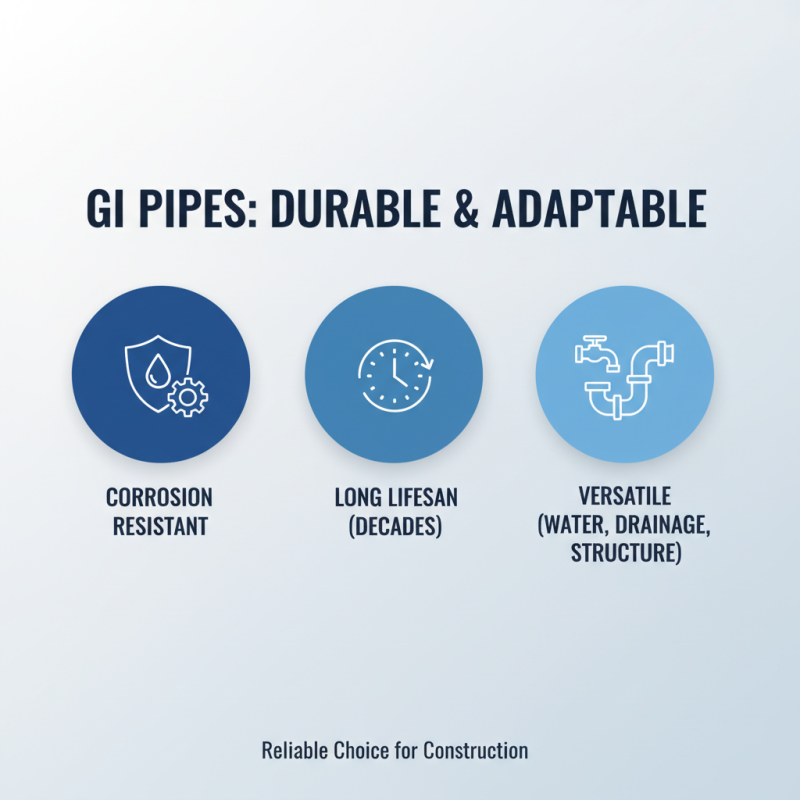

GI pipes, or Galvanized Iron pipes, are widely used in construction due to their remarkable properties. They are durable and resistant to corrosion, making them an ideal choice for various applications. One major benefit is their longevity. These pipes can last for decades, reducing the need for frequent replacements. Another advantage is their adaptability. GI pipes are versatile enough for water supply, drainage, and structural support.

**Tip:** When selecting GI pipes, consider the environment. High humidity or exposure to moisture can affect their lifespan. Proper installation is also essential for optimal performance.

The strength of GI pipes is noteworthy. They can withstand significant pressure, which is vital for plumbing systems. However, improper fitting can lead to leaks. It's crucial to ensure that joints are secured adequately.

**Tip:** Regular maintenance checks can help identify potential issues early on. Small leaks can become major problems if not addressed promptly.

In modern construction, the benefits of GI pipes are clear. They contribute to the efficiency and safety of building projects. However, attention to detail during the installation process is essential.