Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

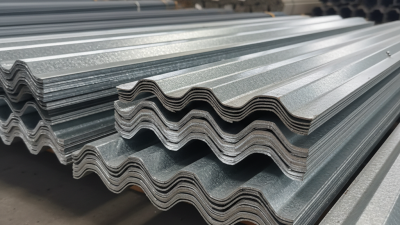

Galvanized Steel Sheet is a vital material in modern construction. It offers corrosion resistance and durability. John Smith, an expert in structural engineering, notes, "Using galvanized steel sheet enhances the lifespan of buildings." This material undergoes hot-dip galvanization, forming a protective zinc layer.

In construction, galvanized steel sheets serve multiple purposes. They are commonly used for roofing, siding, and interior wall panels. Their strength ensures stability in structures, while the zinc coating shields against harsh weather. Imagine a commercial building, proudly displaying its galvanized steel façade, standing resilient against storms.

However, there are considerations. While the protective layer is effective, it can wear over time. Regular maintenance is essential to prevent rust. Moreover, not all construction projects may benefit from its use. Understanding the requirements is crucial for effective application. As attention to detail is paramount, some may overlook the long-term benefits of choosing galvanized steel sheets.

Galvanized steel sheet is a type of steel coated with zinc to prevent rusting. This protective layer is crucial in construction, where exposure to moisture and corrosive environments is common. The zinc coating helps extend the lifespan of the steel, making it a preferred choice for various applications.

According to industry reports, galvanized steel sheets exhibit remarkable corrosion resistance, lasting up to 50 years in certain environments. This characteristic is vital, especially in regions with high humidity or industrial pollutants. Despite its advantages, some construction professionals still opt for non-galvanized steel due to cost concerns. The initial expense can be higher, but the long-term savings on repairs and replacements are often overlooked.

Moreover, the production process of galvanized steel can be energy-intensive. Critics argue that it contributes to higher carbon emissions compared to alternatives. This raises questions about sustainability in the construction industry. While galvanized steel sheets are widely used, the environmental impact of their production warrants further examination. Balancing durability and sustainability is an ongoing challenge for builders and architects alike.

Galvanized steel sheets are essential in construction. Their durability and resistance to corrosion make them popular. The manufacturing process involves coating steel with zinc through hot-dip galvanization or electro-galvanization. This creates a protective layer that prevents rust.

In hot-dip galvanization, steel sheets are immersed in molten zinc. This method ensures a thick, strong coating. Reports indicate that hot-dip galvanized coatings can last 50 years or more, depending on the environment. Electro-galvanization, on the other hand, applies a thinner layer of zinc using electric currents. It provides a smoother finish but may not be as durable.

Manufacturers face some challenges. Zinc may not adhere well if the steel surface isn’t clean. This can lead to premature corrosion. According to industry studies, improper cleaning can reduce the coating lifespan by up to 30%. Quality control in the manufacturing process is crucial to prevent such issues. Ultimately, ensuring a reliable product requires ongoing innovation and testing.

Galvanized steel sheets are a popular choice in construction. This material undergoes a protective zinc coating process, which enhances its durability. According to a recent industry report, galvanized steel experiences up to three times the lifespan of non-galvanized alternatives in various environments. Its resistance to rust and corrosion makes it suitable for outdoor applications, especially in regions with heavy rain or high humidity.

The advantages of using galvanized steel are significant. It reduces maintenance needs, which can lower long-term project costs. Many contractors appreciate its strength and flexibility. The material is light yet sturdy, making it easier to transport and install. Some studies have shown that using galvanized steel can lead to a 30% reduction in construction time compared to traditional materials.

However, there are considerations when choosing galvanized steel. The coating can wear off over time in extreme conditions. Some construction projects may require additional protection, which can add to expenses. Balancing cost and performance is essential. It's crucial to assess the specific needs of each project before deciding on the material.

Galvanized steel sheets are widely used in construction. They offer resistance to corrosion thanks to a protective zinc coating. This makes them ideal for various building applications. Data from the World Steel Association shows that galvanized steel can last up to three times longer than uncoated steel in harsh environments.

In building projects, galvanized sheets are commonly used for roofing and siding. They provide durability and help maintain structural integrity. Additionally, they are often used in the manufacturing of gutters, downspouts, and handrails. According to industry reports, the demand for galvanized steel in construction is expected to grow by 5% annually over the next five years.

However, reliance on galvanized sheets can pose challenges. Their production process can be energy intensive. Some contractors may overlook the need for proper installation, leading to issues down the line. It’s essential to balance the benefits of using galvanized steel with these potential pitfalls. Proper training and awareness in the construction industry are crucial to mitigate these risks.

Galvanized steel sheet is widely used in construction for its resistance to corrosion. This feature significantly extends its lifespan, making it an ideal choice for various applications. However, maintenance remains key to preserving its properties over time.

Regular inspection is essential. While galvanized steel can resist rust, it is not impervious. Scratches or damage to the zinc coating can expose the steel underneath. This can lead to corrosion if not addressed promptly. Clean the surface regularly to remove dirt or debris. Pay attention to joints or welds, as these areas may require additional care.

Using galvanized steel does not mean forgetting about protection. Although it lasts longer than regular steel, factors like humidity and environmental conditions can impact durability. In coastal areas, for example, the salty air can accelerate corrosion. It’s worth considering protective coatings or paint for extra defense. The balance between durability and maintenance is crucial.

| Property | Details |

|---|---|

| Material | Zinc-coated steel sheet |

| Thickness | 0.5 mm to 5 mm |

| Corrosion Resistance | Excellent due to zinc coating |

| Common Uses | Roofing sheets, wall panels, and structural components |

| Maintenance | Minimal; periodic inspection recommended |

| Durability | Lasts 20-50 years depending on environmental conditions |

| Environmental Impact | Recyclable and low environmental footprint |