Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

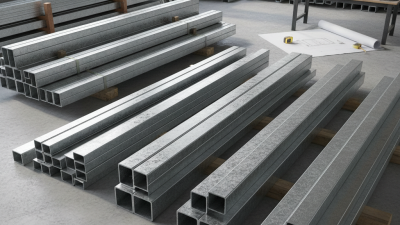

In the realm of construction, the Galvanized Rectangular Pipe stands as a pivotal component known for its durability and versatility. As renowned structural engineer Dr. Emily Carter emphasizes, "The strength and corrosion resistance of galvanized rectangular pipes make them indispensable in modern architectural designs." This innovation not only enhances structural integrity but also contributes to sustainable building practices by providing long-lasting materials that reduce the need for frequent replacements.

Galvanized Rectangular Pipes are commonly utilized in various construction applications, including framing, plumbing, and fencing. Their rectangular shape allows for efficient space usage and seamless integration into diverse design aesthetics. As industries evolve and the demand for robust, cost-effective materials increases, the significance of galvanized rectangular pipes in construction continues to rise. With a growing emphasis on safety and quality, understanding the properties and applications of these pipes is essential for architects and builders aiming to create resilient structures that withstand the test of time.

Galvanized rectangular pipes are steel pipes that have undergone a galvanization process to enhance their resistance to corrosion. This involves coating the pipes with a layer of zinc, which acts as a protective barrier against moisture and other corrosive elements. These pipes are recognized for their durability and longevity, making them an ideal choice for a wide range of applications in construction and industrial settings. Commonly used in structural frameworks, fencing, and scaffolding, galvanized rectangular pipes ensure the stability and strength of a building's structure.

When selecting galvanized rectangular pipes for construction, it's important to consider the specifications such as wall thickness and length, which can influence their strength and suitability for various projects. Proper installation is also crucial; pipes should be securely fastened and supported to prevent any structural failures.

Tips: Always consult with a structural engineer for recommendations on the appropriate grade and size of galvanized rectangular pipes to ensure compliance with local building codes. Additionally, regular inspections can help identify any signs of wear or damage early, extending the lifespan of your construction materials. Ensure that the ends of the pipes are well-cut and deburred to prevent injuries during handling and installation.

| Dimension (inches) | Weight (lbs/ft) | Wall Thickness (inches) | Typical Uses |

|---|---|---|---|

| 2 x 3 | 2.15 | 0.083 | Structural supports, frames |

| 3 x 4 | 3.45 | 0.125 | Construction of fences, gates |

| 4 x 6 | 5.62 | 0.156 | Heavy-duty framework, trailers |

| 6 x 8 | 9.33 | 0.187 | High-strength applications, construction |

| 8 x 10 | 12.65 | 0.25 | Industrial structures, bridges |

Galvanized rectangular pipes are widely used in construction due to their exceptional durability and resistance to corrosion. The manufacturing process of these pipes starts with basic steel, which is then coated with a layer of zinc through a galvanization process. This could either be hot-dip galvanizing, where the steel is submerged in molten zinc, or electro-galvanizing, where an electric current drives the zinc to bond with the steel surface. According to industry reports, the hot-dip method provides a thicker zinc coating, enhancing the pipe's protective qualities, making it suitable for a variety of structural applications.

The composition of galvanized rectangular pipes typically includes elements such as iron and zinc, where the zinc forms a protective layer that prevents rust and extends the lifespan of the product. This layer can help to ensure that the material withstands harsh environmental conditions, which is essential for construction projects. Recent studies suggest that galvanized steel pipes can last up to 50 years or more when properly maintained, making them a cost-effective solution for builders and engineers.

Tip: When selecting galvanized rectangular pipe for construction, consider the environment it will be subjected to. In coastal areas, where humidity and salt can accelerate corrosion, heavier zinc coatings may be necessary to ensure longevity. Always consult with industry standards to ensure compliance and optimal performance.

Galvanized rectangular pipe is an essential component in construction due to its unique properties and benefits.

One of the most significant advantages of using galvanized rectangular pipes is their excellent corrosion resistance.

The galvanization process involves coating the steel with a layer of zinc, which provides a protective barrier against moisture and other corrosive elements. This makes galvanized pipes ideal for outdoor applications and in environments where they may be exposed to various weather conditions, ensuring durability and longevity in construction projects.

Moreover, galvanized rectangular pipes are known for their higher strength-to-weight ratio compared to other construction materials.

This characteristic allows for easier handling and installation, reducing labor costs and time during construction.

Additionally, the structural integrity and stability offered by these pipes make them suitable for various applications, such as framing, fencing, and supports for different structures.

The combination of these advantages makes galvanized rectangular pipes a preferred choice in the construction industry, providing reliable performance and cost-effectiveness.

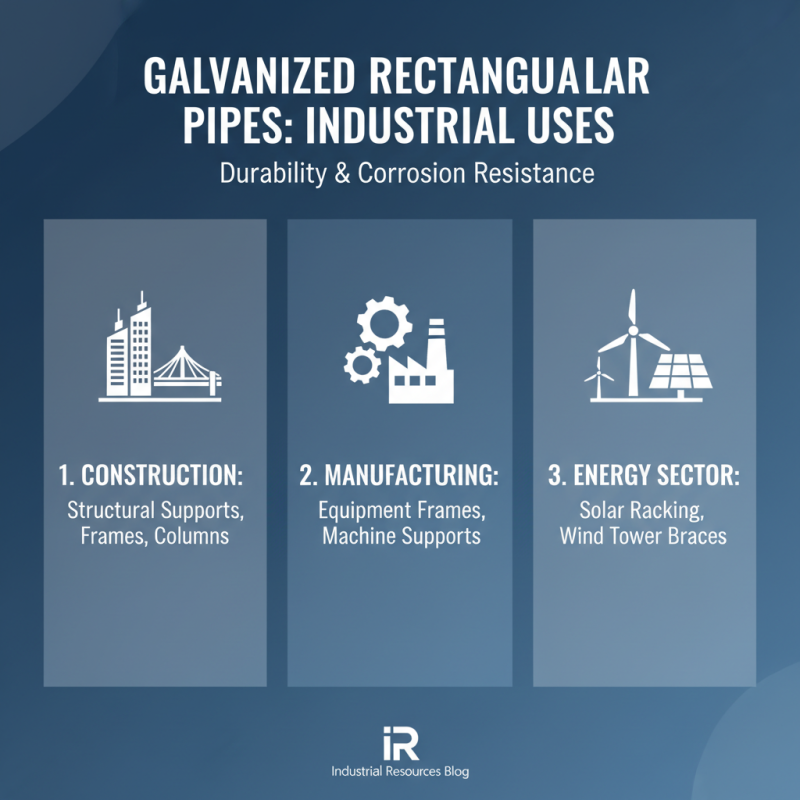

Galvanized rectangular pipes are essential components in various industries due to their durability and resistance to corrosion. One of the primary applications of these pipes is in the construction sector, where they serve as structural supports in buildings, bridges, and other infrastructures. Their rectangular shape allows for efficient use of space and provides strength in both vertical and horizontal applications. This makes them ideal for frames, columns, and braces, offering robust support while minimizing material usage.

In addition to construction, galvanized rectangular pipes are widely utilized in the manufacturing and automotive industries. They are often employed in the production of machinery frames, conveyor systems, and automotive components, where robust and lightweight structures are necessary. Their resistance to rust and environmental wear extends the lifespan of these products, reducing maintenance costs and enhancing operational efficiency. Furthermore, these pipes play a crucial role in various agricultural systems, including irrigation and fencing, demonstrating their versatility and effectiveness across multiple fields.

When considering the maintenance and durability of galvanized rectangular pipes, it's imperative to understand the protection that the galvanization process offers against corrosion. According to a report by the American Galvanizers Association, galvanized steel can offer protection for up to 70 years in a variety of environments, safeguarding it from the effects of moisture and chemicals. The zinc coating, which is applied during the galvanization process, acts as a barrier and sacrificial anode, significantly enhancing the lifespan of the pipe in construction applications.

Regular maintenance of galvanized rectangular pipes is also crucial to ensure their longevity. Factors such as exposure to saltwater, acidic substances, or extreme weather can accelerate the corrosion process, even on galvanized materials. According to industry data, regular inspections and maintenance practices, such as removing debris that could trap moisture and performing visual checks for signs of wear, can help mitigate these risks. Utilizing protective coatings, or touch-up galvanizing in areas where the coating has been damaged, can further enhance the durability of these pipes. Proper maintenance not only protects the structural integrity of the piping but also contributes to overall safety and efficiency in construction projects.

This chart illustrates the usage frequency of galvanized rectangular pipes in various applications within the construction industry. The data indicates that structural support is the primary application, followed by water supply and electrical conduit usage. This information highlights the importance of galvanized rectangular pipes in maintaining the durability and efficiency of construction projects.