Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

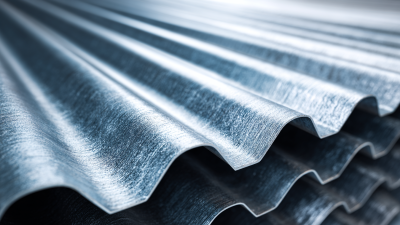

Galvanized coils have become an integral component in various industries due to their exceptional durability and resistance to corrosion. As noted by industry expert Dr. Sarah Thompson, "The rise in demand for galvanized coils is a testament to their versatility and reliability in challenging environments." These coils, which are steel sheets coated with zinc, offer not only strength but also a protective barrier against rust and environmental damage. This unique property makes them ideal for applications ranging from construction and automotive to HVAC and appliances.

In the construction sector, galvanized coils are widely used in roofing, siding, and framing, providing long-lasting solutions that withstand the test of time. The automotive industry also benefits immensely from galvanized materials, as they enhance the longevity of vehicles by protecting critical components from corrosion. With a growing focus on sustainability and longevity, industries are increasingly turning to galvanized coils as a cost-effective and efficient solution, aligning with modern needs for both performance and environmental responsibility. As we explore the applications and advantages of galvanized coils, it is evident that they play a pivotal role in advancing infrastructure and technology across diverse fields.

Galvanized coils are sheets of steel that have undergone a process of galvanization, which involves coating the steel with a layer of zinc to enhance its resistance to corrosion and rust. This protective layer not only increases the lifespan of steel products but also ensures that they maintain structural integrity even in harsh environmental conditions. According to a report by the International Steel Association, galvanized steel accounts for approximately 40% of all steel produced worldwide, highlighting its significant role in the market.

These coils are used extensively across various industries due to their durability and versatility. In construction, galvanized coils are often preferred for roofing, siding, and structural components. The corrosion-resistant properties of galvanized steel make it ideal for outdoor use, where exposure to moisture and atmospheric elements can lead to rapid deterioration. Additionally, the automotive industry utilizes galvanized coils for body panels and chassis components, where weight reduction and corrosion resistance are crucial for performance and safety. The global galvanized steel market was valued at $156 billion in 2021 and is expected to grow steadily, driven by increasing demand from both construction and automotive sectors. This trend underscores the importance of galvanized coils in modern manufacturing and infrastructure development.

Galvanization is a vital process in metal protection, specifically designed to combat corrosion in steel and iron products. The process typically involves coating steel with a layer of zinc, which serves as a sacrificial anode. This means that when steel comes into contact with moisture or other corrosive elements, the zinc corrodes instead of the underlying metal, thereby extending the lifecycle of the product. According to a report from the American Galvanizers Association, galvanized steel can last up to 70 years, significantly reducing maintenance and replacement costs for industries reliant on metal components.

The galvanization process can be conducted through various methods, including hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing involves submerging steel into molten zinc, allowing for an extensive coating that can reach thicknesses of 85 microns or more. Conversely, electro-galvanizing employs an electrical charge to deposit zinc onto the steel surface, resulting in a more uniform and thinner layer, often less than 20 microns. Each method has its specific applications; for instance, hot-dip galvanization is favored in construction and infrastructure due to its robust protective qualities, while electro-galvanization is frequently used in automotive manufacturing, where a smoother surface is required for aesthetic and functional purposes. Reports indicate that the global market for galvanized steel is on the rise, projected to reach approximately $200 billion by 2025, underscoring its critical role across various sectors.

Galvanized coils are steel coils that have been coated with a layer of zinc to enhance their corrosion resistance. This process, known as galvanization, significantly increases the longevity and durability of the steel, making it particularly valuable in various industries. The key properties of galvanized coils include their excellent corrosion resistance, superior formability, and enhanced paint adhesion capabilities. According to a report by the Zinc Institute, galvanized steel can last up to 70 years in harsh environments, making it ideal for applications in construction, automotive, and agriculture industries.

In the construction industry, the use of galvanized coils is prevalent due to their ability to withstand exposure to moisture and harsh weather conditions. The American Galvanizers Association reports that galvanized steel is extensively used for roofing, siding, and structural applications because it not only protects against rust but also maintains structural integrity over time. In the automotive sector, galvanized coils are critical for manufacturing parts that resist corrosion, enhancing vehicle safety and longevity. The use of galvanized materials has resulted in a significant decrease in maintenance costs and a reduction in the carbon footprint associated with replacing corroded components. Overall, the adoption of galvanized coils illustrates the importance of corrosion-resistant materials in today's industrial applications.

Galvanized coils are widely recognized for their durability and corrosion resistance, making them essential in the construction industry. The process of galvanization involves coating steel with zinc to prevent rusting and extending the lifespan of construction materials. According to a report by the International Zinc Association, the demand for galvanized steel products in the construction sector has increased significantly over the past decade, driven by the focus on sustainable building practices and the need for materials that can withstand harsh environmental conditions.

In the construction industry, galvanized coils are utilized for various applications, including roofing, siding, and framing structures. These coils provide a robust solution for builders by enhancing the strength and durability of the final product. A study by the American Iron and Steel Institute highlights that the use of galvanized steel in construction can reduce maintenance costs by up to 50%, as it minimizes the need for frequent repairs or replacements due to corrosion. Additionally, the lightweight nature of galvanized coils allows for easier handling and installation, contributing to faster project timelines and increased efficiency.

Furthermore, the trend towards eco-friendly building materials has propelled the popularity of galvanized coils. Their recyclability aligns with the industry's goal of reducing environmental impact. According to a report from Research and Markets, the global market for galvanized steel is projected to reach $227 billion by 2025, reflecting its growing significance in sustainable construction practices. This demonstrates that galvanized coils not only meet the practical needs of the construction industry but also support broader environmental goals.

This chart illustrates the usage percentage of galvanized coils across various industries, highlighting the significant role they play, particularly in the construction sector.

Galvanized coils, which are steel sheets coated with a layer of zinc, play a crucial role in automotive manufacturing due to their enhanced resistance to corrosion and rust. This property is particularly beneficial in vehicles, which are frequently exposed to varying weather conditions, road salts, and other environmental factors that can lead to degradation over time. As such, manufacturers prefer galvanized coils for various components, including body panels, frames, and structural parts, where longevity and durability are essential.

In addition to corrosion resistance, galvanized coils provide excellent paint adhesion, which is vital for maintaining the aesthetic appeal of vehicles. The zinc coating allows for smoother surfaces that enhance the finish and durability of the paint applied to the vehicle. This is especially important as consumers increasingly expect not only functional performance but also high-quality appearances. Furthermore, using galvanized steel can help reduce manufacturing costs, as it minimizes the need for additional coatings and treatments, thereby streamlining the production process while still meeting stringent safety and quality standards in the automotive industry.