Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

As industries increasingly shift towards sustainable manufacturing practices, the role of Hot Rolled Coils is becoming more critical than ever. According to a recent report by the World Steel Association, steel production accounts for approximately 7% of global CO2 emissions, highlighting the urgent need for sustainable solutions within the sector. Hot Rolled Coils, a staple in construction and manufacturing, face significant scrutiny due to their production methods, which traditionally involve high energy consumption and emissions. However, advancements in technology and the development of eco-friendly processes are paving the way for a greener future. Research indicates that implementing innovative techniques could reduce the carbon footprint of hot rolling processes by up to 30%, illustrating the potential for Hot Rolled Coils to align with global sustainability goals. This article explores the challenges and opportunities facing Hot Rolled Coils in the context of sustainable manufacturing, aiming to shed light on their crucial role in reducing environmental impacts while meeting market demands.

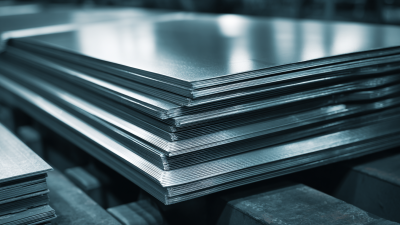

Hot rolled coils are emerging as a key component in sustainable manufacturing practices, driven by the need for environmentally friendly production methods. These coils, produced at high temperatures which lend them excellent ductility and malleability, play a vital role in various industries, including automotive and construction. By utilizing hot rolled coils, manufacturers can reduce energy consumption during the fabrication process, as the material can be shaped into required configurations with less force and machinery operation. This efficient energy usage not only lowers operational costs but also minimizes the carbon footprint associated with manufacturing.

Moreover, the versatility of hot rolled coils supports the growing trend of recycling in manufacturing. The steel produced from hot rolled coils can be easily recycled at the end of its lifecycle, promoting a circular economy that aligns with sustainability goals. This reduces reliance on raw material extraction, conserving natural resources and reducing environmental degradation. As companies increasingly focus on sustainable practices, the integration of hot rolled coils in their production processes showcases a commitment to reducing waste and fostering eco-friendly innovations in the industry.

| Dimension | Value |

|---|---|

| Global Steel Production (2025 Forecast) | 1.8 Billion Tons |

| Percentage of Hot Rolled Coils in Steel Production | 35% |

| Reduction in CO2 Emissions (By 2030) | 20% Reduction |

| Usage of Recycled Materials in Hot Rolled Coils | 60% |

| Projected Growth of Sustainable Hot Rolled Coils Market (2022-2027) | 7.5% CAGR |

| Number of Companies Adopting Sustainable Practices | 150+ |

The production of hot rolled coils is undergoing a revolutionary transformation thanks to innovative technologies focused on enhancing sustainability in manufacturing. Automation and digitalization are at the forefront, allowing for more precise control over the production process. Advanced data analytics can monitor the entire operation, optimizing energy usage and reducing waste. This shift not only supports environmental initiatives but also improves operational efficiency, positioning manufacturers to meet the demands of a greener economy.

Tip: Implementing IoT technology can provide real-time data insights, helping manufacturers adjust parameters on-the-fly for optimal performance and minimal waste.

Furthermore, the introduction of eco-friendly technologies, such as electric arc furnaces (EAF), greatly reduces carbon emissions compared to traditional methods. EAFs utilize scrap metal as the primary input, making it a more sustainable choice that contributes to a circular economy. As these technologies become more prevalent, they promise to create a more resource-efficient production landscape.

Tip: Consider exploring partnerships with technology providers to stay ahead in implementing these sustainable practices and technologies in your operations.

In the realm of sustainable manufacturing, the implementation of eco-friendly practices in producing hot rolled coils has garnered attention. Several companies have taken significant steps toward integrating sustainable methods, showcasing the potential for reduced environmental impact. One notable example is a leading steel manufacturer that utilized renewable energy sources like solar and wind power in its production processes. By revamping its facilities to harness these energy forms, the company was able to cut down its carbon footprint significantly while maintaining high production standards.

Another successful case study can be seen in a collaborative project between a hot rolled coil producer and a waste management firm. By innovatively using recycled materials in the coil production process, the partnership demonstrated the viability of circular economy principles. This initiative not only reduced waste but also lowered costs associated with raw material procurement. As more manufacturers look to adopt similar sustainable practices, these case studies serve as a blueprint, highlighting the strategic benefits of sustainability in the hot rolled coil industry.

The transition to sustainable manufacturing in the steel industry faces significant challenges, particularly in the production of hot rolled coils (HRC). According to the World Steel Association, the steel industry accounts for approximately 7% of global CO2 emissions. To mitigate this impact, manufacturers must adopt eco-friendly practices, such as utilizing electric arc furnaces (EAFs) that produce fewer emissions compared to traditional blast furnaces. Reports indicate that EAFs can reduce CO2 emissions by about 60% when using scrap steel, making them a pivotal solution for greener HRC production.

However, technological and economic barriers hinder the widespread adoption of these methods. The initial capital investment for EAF technology is substantial, posing a challenge for smaller manufacturers. Moreover, sourcing sufficient amounts of scrap steel can be difficult, especially in regions with limited recycling infrastructure. A study by McKinsey found that the integration of renewable energy sources in steel production could cut operating costs by up to 30% over time. Innovating recycling processes and investing in alternative raw materials will be essential to overcoming these hurdles and ensuring that hot rolled coils can contribute to a more sustainable future in manufacturing.

The production of hot rolled coils (HRC) is undergoing a significant transformation as sustainability becomes a priority in manufacturing. Future trends indicate a shift towards more energy-efficient processes, where manufacturers are exploring advanced technologies such as electric arc furnaces (EAF) and hydrogen-based reduction methods. These innovations not only minimize greenhouse gas emissions but also enhance resource efficiency, allowing producers to meet the rising demand for sustainable materials in various industries.

In addition to adopting cleaner technologies, sustainability strategies in HRC production will increasingly focus on circular economy principles. This includes prioritizing the use of recycled materials and reducing waste throughout the production cycle. Companies are likely to collaborate with supply chains to develop more sustainable practices, such as using scrap metal and repurposing by-products. The integration of life cycle assessments will also help manufacturers gauge the environmental impact of their operations and make informed decisions that align with global sustainability goals. As the industry adapts, those who embrace these trends will not only contribute to a greener future but also gain competitive advantages in an evolving marketplace.