Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

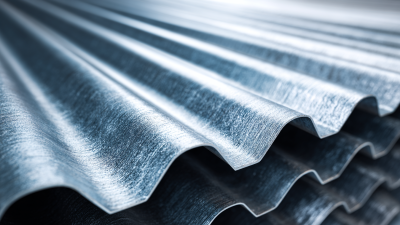

The future of construction and infrastructure development is increasingly leaning towards sustainable and innovative materials, and Gi Corrugated Steel Sheet stands at the forefront of this evolution. As global buyers seek solutions that are not only cost-effective but also environmentally friendly, the demand for Gi Corrugated Steel Sheets is expected to rise significantly. These versatile sheets not only offer strength and durability but are also being enhanced with innovative technologies that promote energy efficiency and reduce waste. This blog will explore the latest advancements in Gi Corrugated Steel Sheet manufacturing and design, highlighting how these developments align with sustainable practices and meet the diverse needs of buyers worldwide. Join us as we delve into the transformative potential of Gi Corrugated Steel Sheets and their pivotal role in shaping a greener future for the construction industry.

The manufacturing landscape of GI corrugated steel sheets is evolving, with a keen focus on sustainability and innovative techniques. According to a recent report by MarketsandMarkets, the global steel market is projected to grow at a CAGR of 3.55% from 2021 to 2026, largely due to innovations in production processes that emphasize eco-friendliness. Manufacturers are adopting advanced technologies such as automated machinery and AI-driven quality control systems, which not only increase efficiency but also minimize waste and energy consumption.

As global buyers seek more sustainable options, the trend toward using recycled materials in the production of GI sheets is gaining traction. The World Steel Association reports that in 2020, around 74% of steel produced was recycled steel, underlining the industry's commitment to sustainable practices. This shift not only reduces the carbon footprint but also aligns with the increasing demand for green building materials in construction projects worldwide.

Tips: When sourcing GI corrugated steel sheets, consider suppliers who prioritize sustainability in their manufacturing processes. Look for certifications that verify the use of recycled materials and energy-efficient technologies. Additionally, stay informed about emerging trends in coatings that enhance durability while still being eco-friendly, offering better protection against corrosion with less environmental impact.

The production of Gi corrugated steel sheets is on the brink of a transformative shift, driven by innovative technologies that enhance efficiency and sustainability. From advancements in material science to the integration of smart manufacturing processes, the industry is poised to redefine its approach to production. Companies are now leveraging automation and artificial intelligence to optimize production lines, significantly reducing waste and energy consumption. These technologies not only streamline the manufacturing process but also ensure a higher quality product, meeting the evolving demands of global buyers.

Moreover, the push for sustainability has led to the adoption of eco-friendly practices within the production cycle. Innovations such as the use of recycled materials and energy-efficient machinery are becoming standard, enabling manufacturers to reduce their carbon footprint. As the world gravitates towards greener solutions, the integration of these sustainable practices in Gi steel sheet production not only satisfies regulatory requirements but also aligns with the growing consumer preference for environmentally responsible products. This evolution in technology and sustainability is set to revolutionize the industry, making Gi corrugated steel sheets a leading choice for construction and infrastructure projects worldwide.

The sustainable practices in the Gi corrugated steel industry are paving the way for a greener future. As global buyers become increasingly conscious of their environmental footprint, innovations in materials and production processes are essential.

One promising alternative that has gained attention is bamboo, a rapidly renewable resource known for its high tensile strength. Utilizing bamboo not only reduces reliance on steel but also supports sustainable construction methods, particularly in regions like North-East India where affordability and eco-friendliness are paramount.

Tips to consider for sustainable building practices include integrating bamboo as a substitute for traditional steel reinforcement in concrete. This innovation can significantly lower costs while enhancing the structural integrity of constructions. Additionally, embracing recycled materials in Gi corrugated steel production can further decrease environmental impact, making it a viable option for eco-conscious buyers.

Moreover, adopting modular construction techniques can streamline the building process, reducing waste and resource consumption. By prioritizing these sustainable solutions, the Gi corrugated steel industry can not only meet the demands of global buyers but also contribute to a more sustainable future.

The global market for galvanized steel sheets, particularly Gi (galvanized iron) sheets, is witnessing significant growth, driven by robust demand across various industries. According to recent projections, the stainless steel sheet market is expected to expand from $112.43 billion in 2023 to $167.48 billion by 2030, at a compound annual growth rate (CAGR) of 5.9%. This surge reflects the increasing reliance on galvanized steel in construction, automotive, and manufacturing sectors, as companies seek durable and sustainable materials.

As global buyers emphasize eco-friendly solutions, the innovations in Gi corrugated steel sheets will play a crucial role. The shift toward advanced alloys and green steel production methods is generating new opportunities for companies to meet environmental standards while enhancing product performance. Notably, the demand for zinc, a critical component in the galvanization process, is also on the rise, particularly in regions with developing economies.

Tips:

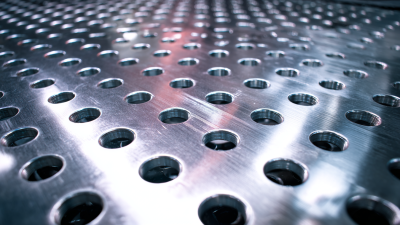

The evolving landscape of corrugated steel sheets is increasingly shaped by the need for sustainability. Among the most promising innovations are eco-friendly coatings, which not only enhance the aesthetic appeal of Galvanized Iron (Gi) steel sheets but also significantly improve their longevity. These coatings are formulated from natural materials that minimize environmental impact while providing robust protection against corrosive elements. By integrating such coatings into the manufacturing process, manufacturers can ensure that their products withstand the test of time, ultimately resulting in reduced maintenance costs and extended service life.

Moreover, the application of eco-friendly coatings offers a dual benefit: they enhance the durability of Gi steel sheets while aligning with global sustainability goals. As buyers become more conscious of their environmental footprint, the demand for products that embody sustainable practices is rising. The incorporation of these coatings into the production of Gi steel sheets exemplifies a shift towards greener solutions in the construction and manufacturing sectors. By investing in innovations that prioritize environmental stewardship, stakeholders can contribute to a more sustainable future while enjoying the practical benefits of longer-lasting materials.