Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Hot Rolled Coils play a pivotal role in modern manufacturing, serving as essential materials across various industries. According to the World Steel Association, hot rolled steel accounts for nearly 80% of the total steel production, underscoring its significance in sectors such as construction, automotive, and machinery fabrication.

The unique properties of hot rolled coils, including their flexibility and strength, make them ideal for applications requiring durability and weight management. Industry forecasts project a continuing demand increase for hot rolled products, driven by infrastructure developments and the global push for sustainable construction practices.

This essential guide will delve into the characteristics, manufacturing process, and applications of Hot Rolled Coils, providing valuable insights for manufacturers and engineers looking to enhance their production efficiencies and material selection strategies.

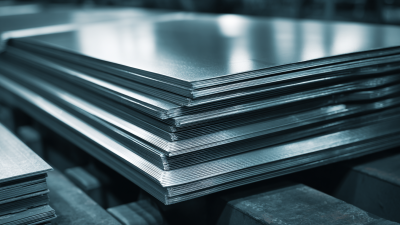

Hot rolled coils are a fundamental component of contemporary manufacturing processes, playing a vital role in various industries, including automotive, construction, and appliances. These coils are produced by heating steel above its recrystallization temperature and then rolling it into sheets. Their malleable and ductile nature makes them ideal for applications that require a combination of strength and flexibility. The ability to shape and mold hot rolled coils into numerous products has revolutionized manufacturing, allowing for greater design freedom and efficiency.

Tips: When selecting hot rolled coils for your projects, consider the material specifications and the desired properties, such as thickness, width, and finish. Understanding these parameters will help you choose the right coil for your specific application, ensuring optimal performance and durability.

The versatility of hot rolled coils extends beyond their immediate use; they serve as the backbone for further processing, such as cold rolling, coating, and welding. Manufacturers benefit from the low cost and rapid production capabilities of hot rolled materials, which streamline the supply chain and reduce lead times. As industries continue to innovate and expand, the importance of hot rolled coils in reducing weight while maintaining structural integrity becomes increasingly significant.

Tips: Regularly assess the quality of your hot rolled coils to avoid defects that may affect production efficiency. Establishing strong relationships with reliable suppliers can ensure consistent quality and timely delivery, which are critical for maintaining production schedules.

Hot rolled coils (HRCs) play a crucial role in various modern manufacturing processes, particularly in industries that require robust and high-quality materials. One of the key advantages of using hot rolled coils is their enhanced structural integrity and ductility, which makes them ideal for applications in automotive, construction, and energy sectors. According to recent industry analysis, the significant demand for HRCs is driven by the increasing production of electric vehicle (EV) batteries, where high-quality steel components are essential for ensuring performance and safety.

In the rapidly evolving lithium battery sector, for instance, the competition among different cell formats—cylindrical, prismatic, and pouch designs—highlights the critical importance of durable materials. Notably, prismatic packaging has emerged as the most prevalent choice for power batteries, favored for its efficient space utilization and thermal management capabilities. Reports indicate that the structural performance of hot rolled coils contributes to the integrity of these battery structures, thereby influencing the overall efficiency and safety of electric vehicles. As manufacturing processes continue to innovate, the demand for hot rolled coils will likely correspondingly increase, affirming their essential role in the modern industrial landscape.

Hot rolled coils play a crucial role in modern manufacturing, serving as a primary material for various applications due to their versatility and strength. The production techniques behind hot rolled coils involve the transformation of heated steel through several processes that can significantly differ from other methods, such as short-process casting technology. Unlike the sequential route of hot rolling for billet opening, short-process casting simplifies production but may not provide the same material properties that are vital for heavy-duty applications. As manufacturers seek to optimize their processes, understanding the nuances between these techniques becomes essential to meeting specific product requirements.

Recent market analyses indicate a shift in the dynamics of hot rolled coil demand, particularly influenced by fluctuating manufacturing activities in key regions like China. Reports forecast a decline in hot-rolled coil prices as weak manufacturing demand is anticipated to persist, driven by a downturn in purchasing managers' indexes. Conversely, significant investments in electrical steel production by major companies reflect a broader trend towards advanced steel solutions, emphasizing the need for innovative production methods. With the global hot rolled coil steel market projected to reach USD 435.65 billion by 2030, understanding these production techniques will be vital for manufacturers looking to stay competitive in an evolving market landscape.

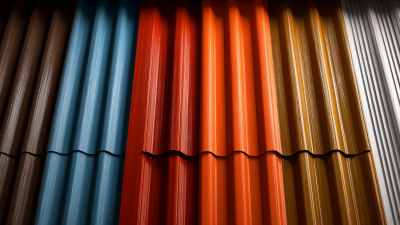

Hot rolled coils play a crucial role in modern construction, primarily due to their strength and versatility. These coils, produced by rolling steel at high temperatures, ensure enhanced ductility and workability, making them an ideal choice for various structural applications. In construction, hot rolled coils are commonly used for building frames, reinforcements, and support structures, providing the necessary stability and durability for modern engineering projects.

Hot rolled coils play a crucial role in modern construction, primarily due to their strength and versatility. These coils, produced by rolling steel at high temperatures, ensure enhanced ductility and workability, making them an ideal choice for various structural applications. In construction, hot rolled coils are commonly used for building frames, reinforcements, and support structures, providing the necessary stability and durability for modern engineering projects.

Moreover, hot rolled coils are integral to the production of a variety of components used in construction. Their applications extend to the manufacturing of beams, columns, and sheets, as they serve as foundational materials in both residential and commercial buildings. The ease of manipulation and welding characteristics of hot rolled steel facilitate its use in different forms, thereby catering to the evolving needs of the construction industry. As infrastructure projects grow and demand for robust materials rises, hot rolled coils remain at the forefront, significantly impacting the sector's advancement.

When selecting the right type of hot rolled coil for your manufacturing needs, it's crucial to consider several factors that align with your specific requirements. First, assess the coil's thickness and width, as these dimensions significantly impact its suitability for different applications. Thicker coils provide greater strength, which is vital for structural components, while thinner coils are preferable for products requiring flexibility and ease of shaping.

Another essential aspect to consider is the material grade of the hot rolled coil. Different grades offer varying levels of hardness, weldability, and corrosion resistance, affecting overall performance in production.

Additionally, understanding the surface finish can enhance your choice; a rough surface may be beneficial for applications requiring improved adhesion, whereas a smoother finish is often desired for aesthetic elements. By carefully evaluating these characteristics, you can choose the optimal hot rolled coil that meets both functional and budgetary criteria for your manufacturing projects.