Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

As industries continue to evolve, the demand for high-performance materials like Cr Steel Sheet is on the rise, reflecting changes in manufacturing and construction sectors. According to a recent market analysis by Grand View Research, the global demand for high-strength steel is projected to reach over 200 million tons by 2025, driven by its widespread applications in automotive and construction industries.

Cr Steel Sheet, characterized by its excellent corrosion resistance and mechanical properties, plays a crucial role in various alternatives to traditional materials. With this growing interest, understanding the key features and benefits of Cr Steel Sheet becomes vital for engineers and decision-makers alike.

In this blog, we outline ten essential facts about Cr Steel Sheet that will equip you with the knowledge needed to leverage this material effectively in your projects.

Cr Steel Sheet, characterized by its excellent corrosion resistance and mechanical properties, plays a crucial role in various alternatives to traditional materials. With this growing interest, understanding the key features and benefits of Cr Steel Sheet becomes vital for engineers and decision-makers alike.

In this blog, we outline ten essential facts about Cr Steel Sheet that will equip you with the knowledge needed to leverage this material effectively in your projects.

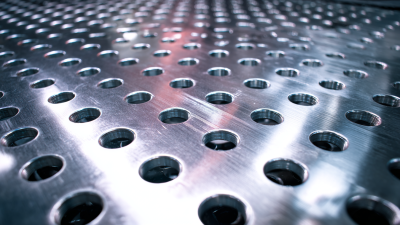

When it comes to industrial materials, Cr steel sheet stands out for its unique composition, which blends chromium with carbon steel. This combination not only enhances the steel's strength but also improves its resistance to corrosion, making it a preferred choice in a variety of applications. The chromium content in the steel forms a protective oxide layer, which bolsters the sheet's durability and extends its lifespan, particularly in harsh environments where exposure to moisture and chemicals is common.

Cr steel sheets, known for their impressive strength and corrosion resistance, play a crucial role across various industries. In the automotive sector, these sheets are widely used in manufacturing chassis and body components, where durability and lightweight characteristics are essential for enhancing fuel efficiency and safety. Their ability to withstand harsh conditions makes them ideal for parts exposed to weathering, ensuring longevity and performance in modern vehicles.

In the construction industry, Cr steel sheets are favored for structural applications due to their resilience and versatility. They can be found in various structures, including buildings, bridges, and towers, providing the necessary support while reducing overall weight. Additionally, the energy sector has recognized the benefits of Cr steel sheets in producing energy-efficient solutions, such as wind turbine components and solar panel frameworks. These applications not only highlight the material's adaptability but also underscore its importance in advancing technology and sustainability initiatives.

| Fact | Description | Key Applications |

|---|---|---|

| Corrosion Resistance | Cr steel sheets offer excellent resistance to rust and corrosion, making them suitable for harsh environments. | Construction, Automotive |

| Strength-To-Weight Ratio | They provide a favorable strength-to-weight ratio, enhancing structural efficiency. | Aerospace, Shipbuilding |

| Formability | Cr steel sheets can be easily formed into various shapes, making them versatile for different applications. | Manufacturing, Home Appliances |

| Weldability | These sheets can be welded efficiently without compromising their properties. | Construction, Fabrication |

| Heat Resistance | Cr steel exhibits high resistance to heat, making it ideal for high-temperature applications. | Power Generation, Petrochemical |

| Surface Finish | They can be treated to achieve a variety of finishes, enhancing aesthetics and functionality. | Consumer Goods, Furniture |

| Sustainability | Cr steel is recyclable, contributing to sustainable manufacturing practices. | Construction, Infrastructure |

| Cost-Effectiveness | These sheets are often more economical compared to other high-strength materials. | General Manufacturing, Agriculture |

| Availability | Cr steel sheets are widely available in various sizes and thicknesses for different requirements. | Wholesale, Retail |

| Innovations | New formulations and treatments continue to enhance the properties of Cr steel sheets. | Automotive, Aerospace |

The manufacturing process of Cr steel sheets involves several critical steps to ensure high-quality and durable steel products. Initially, chromium is added to steel to enhance its corrosion resistance and improve overall mechanical properties. This chromium content typically ranges from 4% to 12%, depending on the desired characteristics of the final product. Once the alloy is prepared, the process begins with melting the raw materials in an electric arc furnace. This method provides superior control over the composition and temperature.

Following the melting process, the molten steel is refined and then cast into slabs or blooms. These initial shapes are subjected to hot rolling, where they are heated and passed through rollers to achieve the desired thickness. Hot rolling is vital as it improves the steel’s microstructure, enhancing both its strength and ductility. After hot rolling, the steel is cooled and can undergo cold rolling processes to achieve even tighter tolerances and a smoother surface finish. Finally, the Cr steel sheets are subjected to various treatments, including annealing and surface coating, to further enhance their properties and prepare them for various applications across industries.

When comparing Cr steel sheets with other steel variants, it's important to explore their distinct properties and applications. Cr steel sheets typically exhibit enhanced corrosion resistance, making them ideal for environments where moisture and chemicals are prevalent. For instance, recent studies on 2205 duplex stainless steel variants show that while one variant has a higher pitting resistance, Cr steels are known for their reliability in similar conditions. This makes them a preferred choice in industries where failure is not an option, such as aerospace and automotive sectors.

Furthermore, advancements in production techniques, like modified binder jet printing, have made it possible to achieve fully dense stainless steel parts, including those with significant chromium content. The mechanical properties of these parts can differ markedly from those of standard steel sheets, showcasing how the addition of chromium alters performance. As manufacturers continuously seek to enhance the durability and functionality of steel products, the comparison between Cr steel sheets and other steel variants is critical for making informed decisions regarding material selection for specific applications.

When it comes to maintaining the longevity and performance of Cr steel sheets, regular inspections are essential. Periodically check for signs of corrosion or wear, as early detection can prevent more significant issues down the road. Keeping the surface clean is equally important; any dirt or debris can trap moisture, leading to corrosion. A simple wash with mild soap and water, followed by thorough drying, can help keep your sheets in optimal condition.

Another vital tip is to apply anti-corrosion coatings. These coatings create a protective layer that helps shield the steel from harsh environmental conditions. Consider using a primer specifically designed for metal surfaces, followed by a suitable topcoat to enhance durability. Additionally, if the sheets are exposed to extreme temperatures or chemicals, selecting appropriate protective finishes can significantly improve performance.

Finally, ensure proper storage of Cr steel sheets by keeping them in a dry, ventilated area. Avoid stacking them directly on the ground to prevent moisture absorption. Instead, use pallets to elevate the sheets and protect them from ground-level dampness. Employing these maintenance tips will not only extend the lifespan of your Cr steel sheets but also enhance their overall performance in various applications.