Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

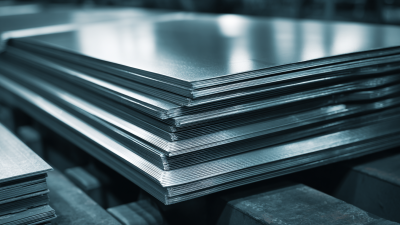

In the construction industry, the utilization of materials that provide durability and resistance to corrosion is paramount. Galvanized coils have emerged as a vital component in various construction projects, primarily due to their enhanced longevity and structural integrity. According to a report by the Global Metal Coating Industry, the market for galvanized products is expected to grow significantly, driven by increasing demand for resilient building materials. These coils, coated with zinc to prevent rust and deterioration, are indispensable in structural applications, roofing, and siding. Their ability to withstand harsh environmental conditions without compromising strength is a key reason for their rising popularity. This guide aims to explore effective strategies for utilizing galvanized coils in construction projects, ensuring optimal performance and sustainability.

Galvanized coils have become a staple in construction projects due to their remarkable properties and benefits. These coils, made of steel that has been coated with zinc, offer excellent corrosion resistance, making them ideal for applications in various environments, especially those exposed to moisture and harsh weather conditions. The zinc coating protects the steel beneath, extending its lifespan and maintaining structural integrity.

This durability translates to lower maintenance costs and a longer duration before replacements are necessary.

Galvanized coils have become a staple in construction projects due to their remarkable properties and benefits. These coils, made of steel that has been coated with zinc, offer excellent corrosion resistance, making them ideal for applications in various environments, especially those exposed to moisture and harsh weather conditions. The zinc coating protects the steel beneath, extending its lifespan and maintaining structural integrity.

This durability translates to lower maintenance costs and a longer duration before replacements are necessary.

When using galvanized coils in construction, consider the following tips: First, ensure the coils are sourced from reputable suppliers to guarantee the quality of the zinc coating. Second, pay attention to the thickness of the coils; a thicker layer of zinc provides better protection against corrosion. Lastly, during the installation process, avoid cutting or damaging the galvanized surface, as this can expose the steel below and negate the benefits of galvanization.

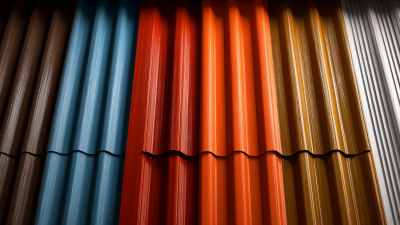

Additionally, galvanized coils are versatile and can be easily shaped and formed for a variety of applications, such as roofing, fencing, and structural supports. Their lightweight nature, combined with strength, simplifies transportation and handling on-site. Being an eco-friendly choice, as they are recyclable, galvanized coils contribute positively to sustainable construction practices.

Galvanized coils are essential materials in construction projects due to their durability and resistance to corrosion. One of the primary applications of galvanized coils is in roofing and siding systems. Their ability to withstand harsh weather conditions while maintaining structural integrity makes them a popular choice for both residential and commercial buildings. The zinc coating applied during the galvanization process protects the steel from moisture, ensuring a longer lifespan and reducing maintenance costs.

Another significant application of galvanized coils is in the manufacturing of metal framing and supports. In addition to enhancing the stability of structures, galvanized steel framing is often employed in high-rise buildings and other large projects where strength and reliability are paramount. Moreover, galvanized coils are extensively used in the automotive and transportation sectors, providing essential components that require sturdiness and protection against rust. The versatility and flexibility of galvanized coils make them an indispensable resource across various construction applications, ensuring that projects meet safety and longevity standards.

| Application Area | Purpose | Common Thickness (mm) | Benefits |

|---|---|---|---|

| Residential Roofing | Weather protection | 0.4 - 0.7 | Rust resistance, longevity |

| Fencing | Boundary protection | 1.0 - 1.5 | Durability, low maintenance |

| Structural Supports | Load-bearing | 2.0 - 3.0 | Strength, corrosion resistance |

| HVAC Ductwork | Air distribution | 0.5 - 1.0 | Thermal efficiency, minimal leakage |

| Railings | Safety and aesthetics | 1.5 - 2.0 | Visual appeal, strength |

When working with galvanized coils in construction projects, proper handling and storage on site is crucial to maintain their integrity and longevity. Galvanized coils, coated with a layer of zinc to prevent rusting, require careful treatment to avoid damage during transportation and installation. To ensure these materials remain in optimal condition, it is important to implement best practices right from the moment they arrive on-site.

Tip: Always store galvanized coils on a flat, elevated surface to prevent moisture accumulation. Using wooden blocks or pallets can keep the coils dry and reduce the risk of corrosion. Additionally, cover the coils with a tarpaulin or waterproof sheet if they must be left exposed to the elements. This protective measure minimizes direct exposure to rain and UV rays, which can slowly deteriorate the protective zinc layer.

Tip: When handling the coils, use gloves and avoid dragging them along rough surfaces. This facilitates a safer working environment while preventing scratches and abrasions that could compromise the galvanization. If coils must be moved, use appropriate lifting equipment to avoid any accidental damage. Following these handling and storage practices will significantly enhance the life expectancy and performance of galvanized coils in construction applications.

When it comes to the proper installation of galvanized coils in construction, attention to detail can significantly improve the longevity and performance of the structure. One key technique is ensuring that the surface preparation is thorough, which can increase corrosion resistance by up to 50%, according to a report by the American Galvanizers Association. Cleaning the substrate effectively removes contaminants that could compromise adhesion and lead to premature failure.

To maximize the longevity of galvanized coil structures in construction projects, proper maintenance practices are essential. Regular inspections should be conducted to identify any signs of corrosion or damage. It is important to remove debris and contaminants from the surface, as these can accelerate the deterioration process. Additionally, ensuring proper drainage and ventilation around galvanized structures can help prevent moisture accumulation, which is a leading cause of corrosion.

Innovative tools like the Zinc Coating Life Predictor can assist in predicting the service life of galvanized steel in various environments. By assessing the expected corrosion rates based on environmental conditions, project managers can make informed decisions about maintenance intervals and protective coatings. This proactive approach not only extends the life of the galvanized coils but also enhances the overall durability of the construction project, ensuring that investments are protected over time. Regular maintenance, informed by predictive modeling, can lead to more sustainable and cost-effective use of galvanized coils in the construction industry.