Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

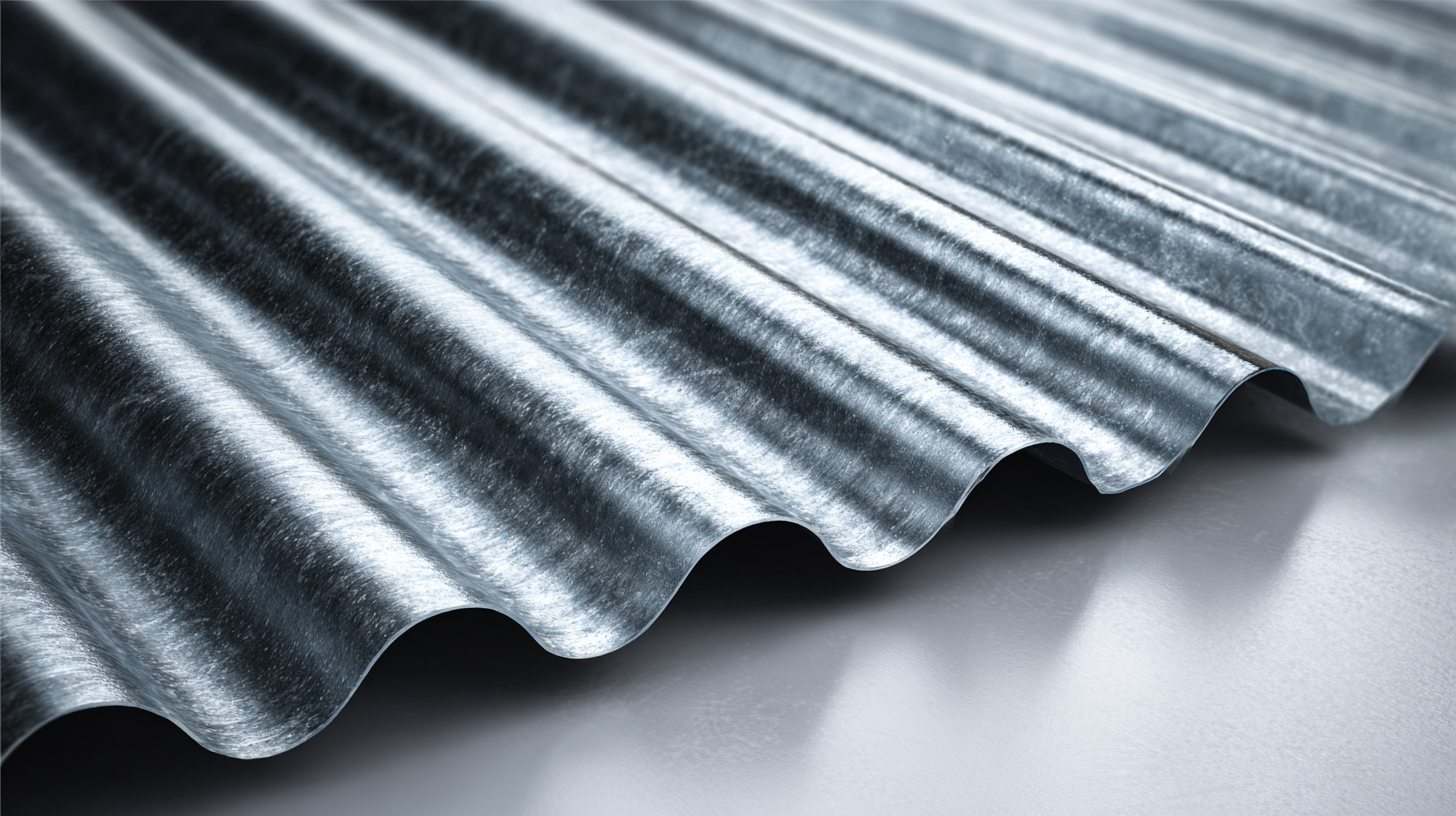

The construction industry has seen significant advancements in material technology, particularly with the rise of Pp Corrugated Steel Sheets. These innovative sheets, known for their exceptional durability and versatility, have become a popular choice in various applications, from roofing to wall cladding. According to a recent report by the Global Steel Innovation Forum, the demand for Pp Corrugated Steel Sheets is projected to grow at a CAGR of 5.6% from 2023 to 2030, driven by their lightweight nature and resistance to environmental stresses. Furthermore, a study by Market Research Future highlights that these materials exhibit high tensile strength while remaining cost-effective, thus making them ideal for sustainable construction practices. As industry trends unveil the potential of Pp Corrugated Steel Sheets, stakeholders are increasingly recognizing their role in enhancing the longevity and resilience of structures in an ever-evolving market.

PP corrugated steel sheets have gained considerable traction in various industries due to their exceptional durability and lightweight properties. These sheets, made with a combination of polypropylene and steel, serve multiple applications, from construction to packaging. According to a recent industry report by Grand View Research, the global market for corrugated steel sheets is expected to reach $77 billion by 2025, highlighting their growing demand. The unique characteristics of PP corrugated steel sheets, such as weather resistance, impact strength, and ease of installation, make them an ideal choice for roofing, wall cladding, and even agricultural uses.

When selecting PP corrugated steel sheets for specific applications, it’s essential to consider factors like thickness, coating types, and exposure conditions. Tips for ensuring long-term performance include proper installation techniques and regular maintenance checks to prevent corrosion. Moreover, choosing sheets with UV protection can significantly extend their lifespan, ensuring they withstand harsh environmental elements.

As industries increasingly focus on sustainability, PP corrugated steel sheets also come with an eco-friendly edge, being fully recyclable. Companies seeking alternatives to traditional materials can benefit from their lightweight nature, reducing transportation costs and energy consumption. Utilizing innovative materials like these can contribute to more sustainable construction practices while enhancing overall project efficiency.

In 2023, the market for PP corrugated steel sheets is witnessing significant transformations driven by innovative trends and heightened demand for sustainable materials. One of the key industry trends is the increasing emphasis on eco-friendly products, with reports indicating that over 60% of manufacturers are seeking sustainable alternatives to traditional materials. This shift is largely attributed to strict environmental regulations and consumers' growing preference for green construction options, positioning PP corrugated steel sheets as a viable solution due to their recyclability and reduced carbon footprint.

Furthermore, advancements in technology are impacting the manufacturing processes of PP corrugated steel sheets. According to a recent market analysis, the adoption of automation and smart manufacturing techniques is projected to improve production efficiency by up to 30% over the next five years. This technological integration not only enhances product durability but also drives down costs, making PP corrugated sheets more competitive in a market that values both performance and price. As industry players continue to innovate, the future of PP corrugated steel sheets looks increasingly promising, influenced by a blend of sustainability initiatives and technological advancements.

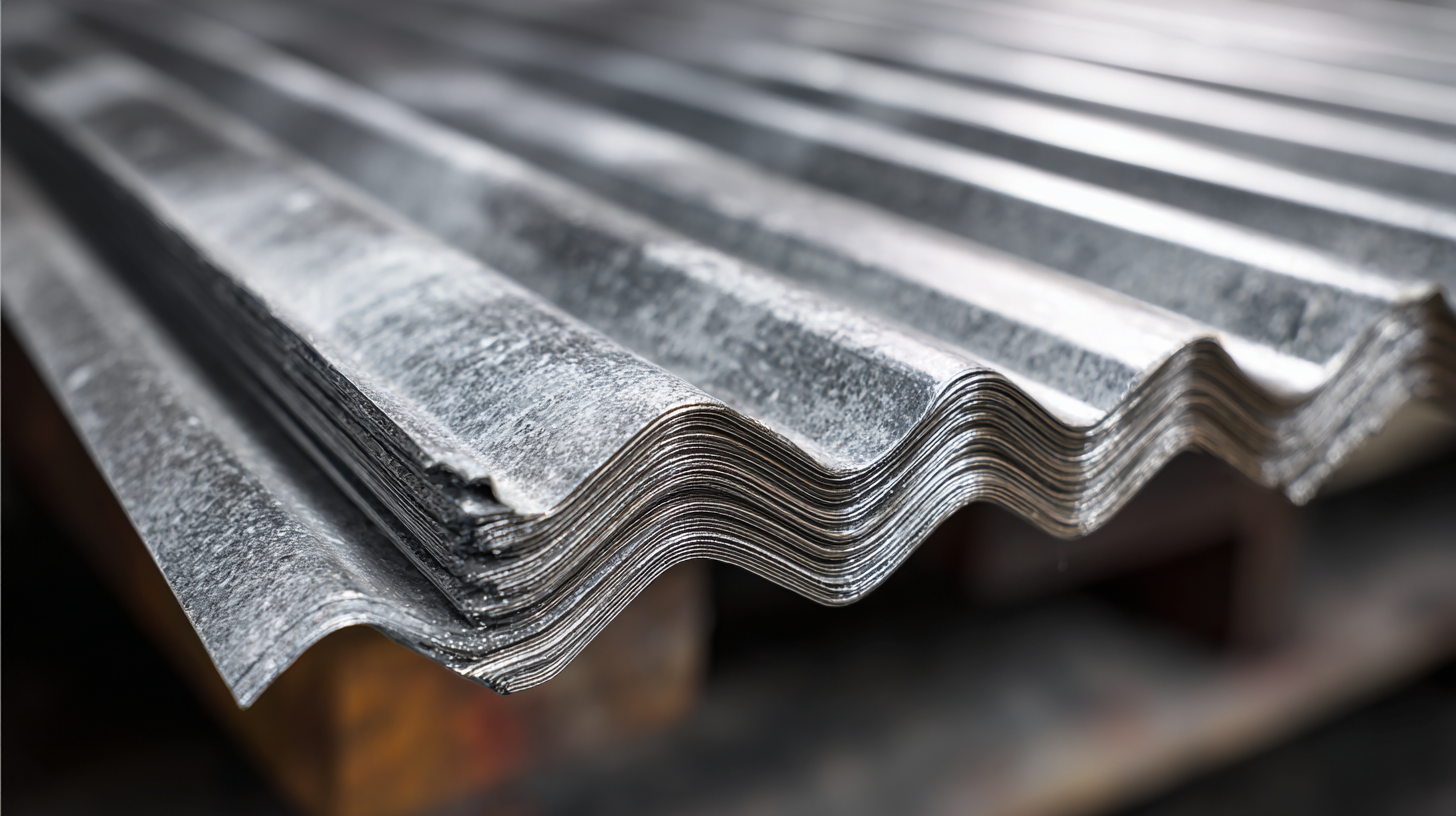

The durability of PP corrugated steel sheets is heavily influenced by a range of factors that industry professionals must consider. One key element is the protective coating applied during the manufacturing process. According to the latest report from Smith & Associates, sheets with a high-quality polymer coating can improve resistance to corrosion and UV radiation by up to 50%, significantly extending their lifespan. This is critical for applications in harsh environments where exposure to the elements can severely impact material integrity.

Another vital factor is the sheet design. The use of advanced engineering techniques allows for optimized rib profiles that enhance structural strength and reduce the risk of deformation under load. Industry studies show that well-designed PP corrugated sheets can withstand impact forces that are 30% higher than those of traditional materials. This is particularly important in sectors such as construction and transportation, where durability and reliability are paramount. As manufacturers continue to innovate, the insights gathered from these trends will guide the future of PP corrugated steel products, ensuring they meet the rigorous demands of modern usage.

The manufacturing landscape in 2023 is witnessing a significant shift towards enhanced durability, particularly in the production of PP corrugated steel sheets. Innovations in manufacturing techniques, such as the integration of specialized metal powders in additive manufacturing, are paving the way for stronger and more resilient materials. According to industry reports, the North American metal powder market is projected to grow significantly as businesses seek efficient manufacturing solutions and advanced materials, thereby accelerating innovation and driving down costs.

To further enhance durability, recent advancements in composite materials are gaining traction. Techniques like the fly ash-silica fume coating and the incorporation of rice husk ash into recycled aggregate concrete are proving to be effective in improving structural integrity and sustainability. Reports indicate an increasing adoption of such methodologies in the building industry, responding to the urgent need for reduced ecological footprints.

Tips: Consider exploring the latest developments in additive manufacturing techniques that utilize nanoparticles and short fibers. Implementing predictive maintenance strategies in manufacturing can also enhance operational efficiency, ensuring your equipment runs optimally and reducing downtime.

The demand for PP corrugated steel sheets has been on the rise in 2023, driven by their unique advantages in various industries, including construction and packaging. These sheets, known for their lightweight yet durable properties, are increasingly favored for their resistance to corrosion and impact. As industries adopt more sustainable practices, the recyclable nature of PP corrugated steel has made it a preferred choice among environmentally conscious consumers.

On the supply side, manufacturers are ramping up production to meet this burgeoning demand. Innovations in production techniques have led to optimized manufacturing processes, reducing costs and increasing output. However, the sector also faces challenges such as fluctuating raw material prices and supply chain disruptions, which can impact availability. Overall, the interplay between growing demand and these supply chain dynamics will shape the market landscape for PP corrugated steel sheets throughout the year.

| Region | Demand (Units) | Supply (Units) | Market Growth Rate (%) | Key Trends |

|---|---|---|---|---|

| North America | 500,000 | 450,000 | 5.2 | Sustainable materials usage |

| Europe | 600,000 | 550,000 | 4.5 | Innovation in coating technologies |

| Asia-Pacific | 800,000 | 850,000 | 6.0 | Increased industrial application |

| Latin America | 300,000 | 250,000 | 3.8 | Focus on cost-effective solutions |

| Middle East & Africa | 200,000 | 180,000 | 2.5 | Emerging market opportunities |