Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Pp Corrugated Steel Sheet for your construction needs is a critical decision that can significantly impact the durability, efficiency, and aesthetic appeal of your project. According to a market analysis by Grand View Research, the global steel sheet market is projected to reach $2.6 trillion by 2025, driven by increasing construction and manufacturing activities.

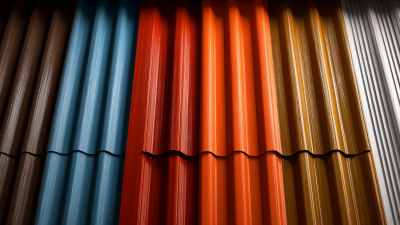

Pp Corrugated Steel Sheets, known for their lightweight and robust properties, have become a preferred choice in various applications including roofing, siding, and packaging. The versatility and resilience of these sheets make them a popular option among builders and designers, especially in regions prone to severe weather conditions.

Understanding the diverse factors such as thickness, coatings, and manufacturers will ensure that you select the ideal Pp Corrugated Steel Sheet that not only meets industry standards but also aligns with your specific project requirements.

When selecting the appropriate PP corrugated steel sheet for construction, understanding the composition and properties is essential for ensuring durability. PP, or polypropylene, is a thermoplastic polymer that contributes to the corrosion resistance of the steel sheet, making it an ideal choice for various environments, including those exposed to moisture and chemicals. This composition not only enhances longevity but also provides flexibility and impact resistance, allowing the sheets to withstand heavy loads without compromising structural integrity.

The properties of PP corrugated steel sheets also play a significant role in their application. Their lightweight nature facilitates easier handling and installation, making them suitable for diverse construction projects. Additionally, the surface finish can be tailored to resist UV degradation, ensuring that color and surface quality remain intact over time. Moreover, these sheets exhibit excellent thermal insulation properties, contributing to energy efficiency in buildings. By understanding these key characteristics, construction professionals can make informed decisions that ensure the longevity and reliability of their projects.

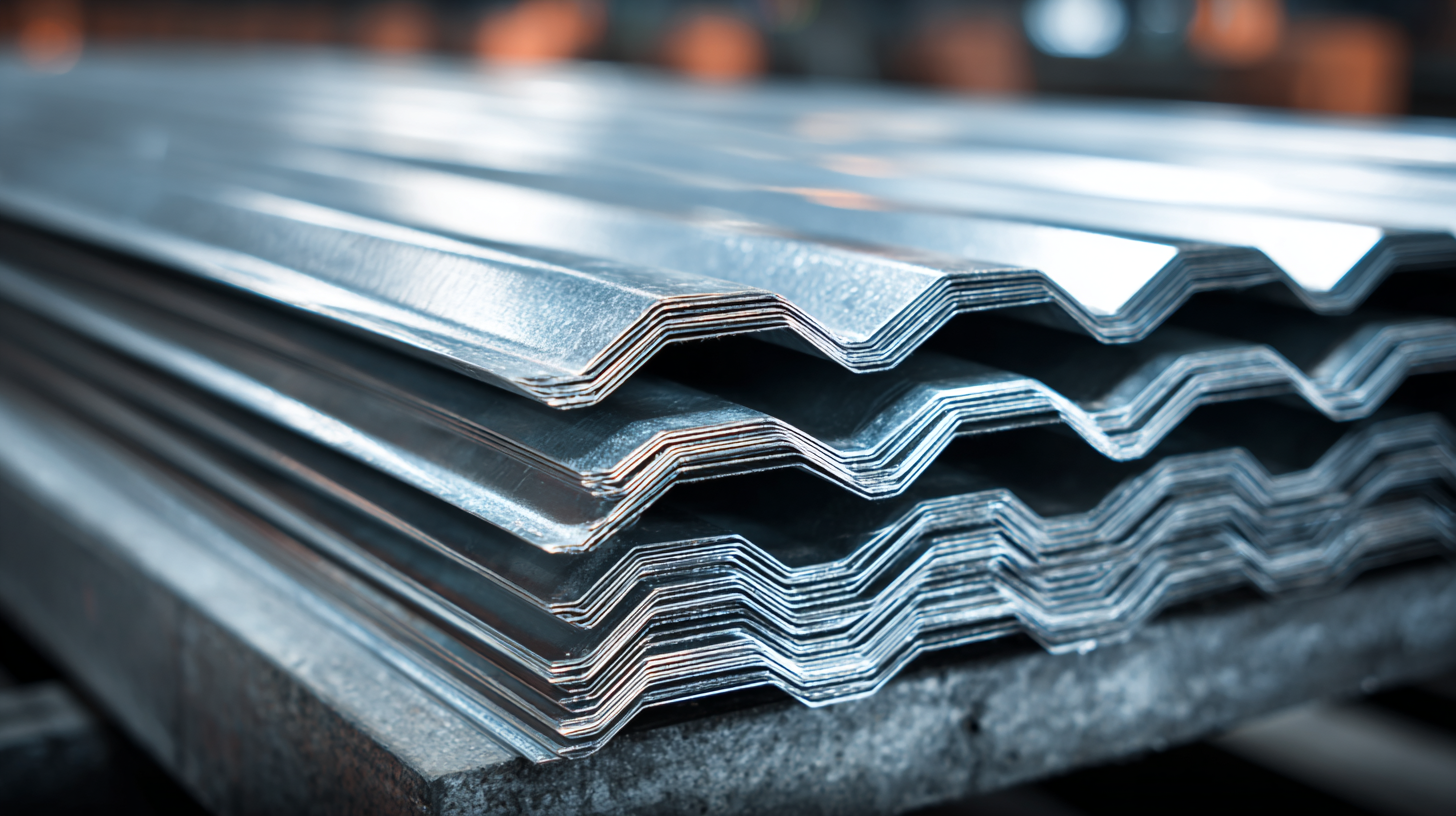

When selecting pp corrugated steel sheets for construction, understanding their load-bearing capacities is crucial. Different types of pp corrugated steel sheets offer varying strengths and durability, which can significantly impact the structural integrity of a building. Factors such as sheet thickness, corrugation height, and material composition contribute to their overall performance under load. For instance, sheets with deeper corrugations typically provide better load distribution and resistance to deformation.

Additionally, evaluating the intended application is essential. For projects requiring high structural support, opting for thicker and more robust sheet options is advisable. In contrast, for lighter applications, such as roofing or temporary structures, thinner sheets may suffice.

Constructing load calculations based on these evaluations ensures that the selected materials meet safety standards and performance expectations. By thoroughly examining the load-bearing capacities of various pp corrugated steel sheet types, builders can make informed choices that align with their specific construction needs.

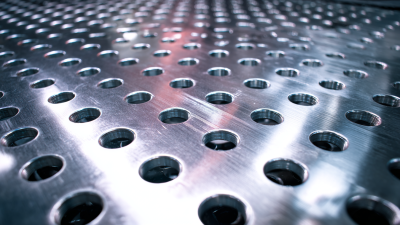

When selecting PP corrugated steel sheets for construction, one of the most critical factors to consider is corrosion resistance. Various materials exhibit different levels of durability against environmental factors. For instance, a recent industry report from the Construction Materials Institute highlighted that galvanized steel sheets demonstrate a zinc coating that significantly enhances corrosion resistance, extending their lifespan by approximately 50% compared to non-coated alternatives. This is particularly pertinent in regions with high humidity or exposure to corrosive elements.

Moreover, polypropylene (PP) coatings offer an additional layer of protection. A study conducted by the International Steel Construction Association revealed that sheets with PP coatings resist harsh chemicals and moisture better than traditional materials, making them ideal for industrial applications. The report found that structures utilizing PP corrugated steel sheets maintained their integrity and appearance over time, reducing the need for costly repairs and replacements. Therefore, understanding the comparative corrosion resistance of these materials is essential for choosing the right PP corrugated steel sheet that meets specific construction needs.

| Material Type | Corrosion Resistance Rating (1-10) | Weight per Square Meter (kg) | Cost per Square Meter ($) | Application Suitability |

|---|---|---|---|---|

| Galvanized Steel | 8 | 7.5 | 5.50 | Residential and Commercial Roofing |

| Aluzinc Steel | 9 | 7.2 | 6.80 | Industrial Applications |

| Pre-Painted Steel | 7 | 6.8 | 7.00 | Architectural Aesthetics |

| Stainless Steel | 10 | 8.0 | 12.00 | High-Durability Applications |

When selecting PP corrugated steel sheets for construction projects, assessing the cost-effectiveness and lifespan becomes paramount, particularly for long-term investments. According to a report by the International Journal of Industrial Research, PP corrugated steel sheets typically last between 20-30 years, outperforming many traditional materials in durability and resistance to various environmental factors. This longevity significantly reduces the need for frequent replacements, driving down maintenance costs substantially.

Moreover, the initial investment in quality PP corrugated steel sheets can lead to significant savings over time. A study from the Construction Materials and Technology Association (CMTA) shows that while the upfront cost may be higher than alternatives like regular steel or plastic sheets, the reduced lifecycle costs—estimated to be up to 30% lower—offer compelling value. The sheets' resistance to corrosion and extreme weather conditions also ensures that they maintain structural integrity, further enhancing their cost-effectiveness in long-term applications. Thus, weighing these factors is essential for making an informed choice that aligns with the project's financial and practical requirements.

When selecting the right thickness and profile for PP corrugated steel sheets, it's essential to consider the specific requirements of your construction project. The thickness of these sheets typically ranges from 0.3 mm to 0.8 mm, with the choice largely dependent on factors such as load-bearing capacity, environmental conditions, and intended use. According to industry reports, sheets with a thickness of 0.5 mm are generally suitable for residential applications, while commercial and industrial uses might require heavier options to withstand greater stress and external forces.

In addition to thickness, the profile of the corrugated steel sheets plays a crucial role in performance. Profiles such as "W" or "U" shapes offer varying levels of strength and flexibility. A study from the Steel Construction Institute highlights that deeper corrugations improve load distribution and are recommended for roofing applications where weather resistance is paramount. By carefully evaluating these aspects based on project needs, you can ensure that the chosen PP corrugated steel sheets will provide durability, effectiveness, and long-term value for your construction endeavors.