Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Galvanized Steel Sheet for your project can be challenging. With various options available, it’s essential to understand their unique properties. Galvanized Steel Sheets are coated with zinc, providing excellent corrosion resistance. This quality makes them suitable for both outdoor and indoor applications.

Consider factors like thickness, finish, and size. The thickness affects durability and weight. A thicker sheet may withstand harsh conditions better. However, it might be harder to manipulate. On the other hand, thinner sheets are easier to work with but less resilient.

Think carefully about your project needs. Aesthetic preferences may influence your finish choice. A smooth finish can enhance appearance, while a rough one can hide imperfections. Remember, selecting the wrong Galvanized Steel Sheet might lead to complications. Reflect on your project's demands before making a decision.

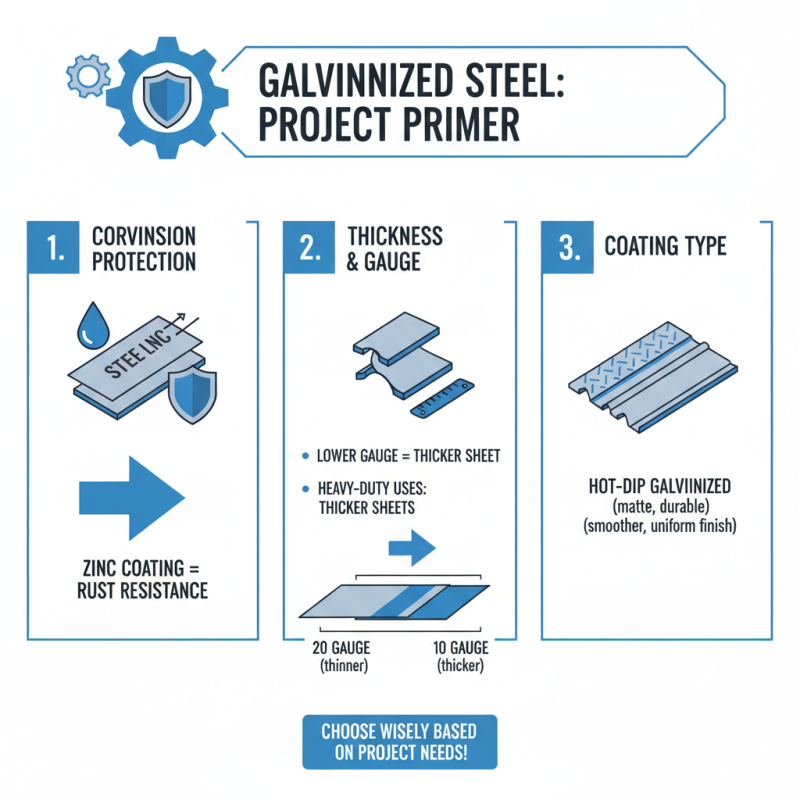

Choosing the right galvanized steel sheet for your project requires a good understanding of its specifications. Galvanized steel sheets are coated with zinc for protection against corrosion. They come in various thicknesses and coatings. The thickness is measured in gauge. A lower gauge number means a thicker sheet. You might need a thicker sheet for heavy-duty applications.

When considering specifications, check the zinc coating weight. This is usually measured in grams per square meter. A higher weight provides better protection but may increase cost. Pay attention to the tensile strength of the sheet as well. This indicates the sheet’s ability to withstand tension without breaking.

**Tips:** Always assess the environment where the steel will be used. If moisture is high, opt for heavier coatings. Consider durability requirements and weight limitations too.

Not every galvanized steel sheet is ideal for every project. Reflect on your specific needs. Is the sheet adequately strong? Will it last in your environment? These questions are crucial in making the right choice.

When selecting galvanized steel sheets, understanding the types available is crucial. Different types serve distinct purposes in construction and manufacturing. Galvanized sheets can be classified into different grades based on their thickness and coating. For instance, some sheets are perfect for roofing due to their durability. Others are tailored for outdoor furniture, providing resistance against weather elements.

Tips: Consider the environment where you'll use the sheet. Exposure to moisture might require a heavier zinc coating.

Moreover, the application also defines the type of galvanized sheet you need. If you're working on a project requiring heavy-duty support, opt for thicker sheets. These sheets can withstand significant weight and pressure. In contrast, lighter sheets are ideal for decorative uses, like signage or fencing.

Tips: Always measure your project space accurately. Incorrect measurements may lead to waste or project delays.

Remember, each project is unique. Sometimes, using a standard grade may not suffice. Reflecting on the project's specific needs can help make a better choice. Consider long-term goals as well. Investing in higher quality sheets might seem costly but could save you money down the line.

When selecting a galvanized steel sheet, several key factors should be considered.

The thickness of the sheet greatly influences its durability and application.

Thicker sheets provide better resistance to damage but may be heavier.

Conversely, thinner sheets are easier to handle but might not withstand heavy loads.

Always assess the specific needs of your project.

The coating weight is another crucial aspect.

A higher coating weight offers better corrosion resistance.

However, achieving the right balance between protection and cost is important.

If the exposure to moisture is limited, a lighter coating might suffice. Evaluate your environment and choose accordingly.

Tips:

Always consult with experts to determine the best fit for your requirements.

Researching similar projects can provide insights into the ideal choices.

Don’t forget to check for potential imperfections in the sheets.

Small flaws can lead to bigger issues down the line.

Prioritize quality over price for lasting results.

Galvanized steel sheets are widely used in various industries due to their durability and resistance to rust. Common applications include construction, automotive, and home appliances. For instance, the construction industry utilizes these sheets for roofing and siding, benefiting from their strength and weather resistance.

In the automotive sector, galvanized steel sheets help reduce weight while enhancing corrosion protection. According to industry reports, nearly 28% of all steel used in cars is galvanized. This ensures safety and longevity, a crucial factor for manufacturers. In home appliances, such as washing machines and refrigerators, galvanized steel sheets are favored for their clean finish and ease of maintenance.

**Tip:** Always check the thickness of the galvanized sheet before purchase. A standard thickness offers both strength and flexibility.

Another application is in agricultural components. Farmers often use galvanized steel for storage bins and equipment due to its ability to withstand harsh environments. However, one must consider potential environmental factors affecting longevity. Corrosion can still occur in extreme conditions, leading to unexpected maintenance costs.

**Tip:** Conduct regular inspections. Detecting rust early can save you time and money.

| Application | Thickness (mm) | Corrosion Resistance | Common Uses |

|---|---|---|---|

| Construction | 0.5 - 3.0 | High | Roofing, Wall panels |

| Automotive | 0.7 - 1.5 | Moderate | Body panels, Frames |

| Agriculture | 0.5 - 2.0 | High | Storage bins, Fencing |

| Furniture | 0.4 - 1.2 | Moderate | Table frames, Chairs |

| Electrical | 0.5 - 1.0 | High | Conduit, Electrical enclosures |

When choosing galvanized steel sheets, it's important to consider their maintenance and durability. Galvanized steel is coated with zinc, which protects it from rust and corrosion. This makes it a popular choice for outdoor projects. However, over time, even galvanized steel can show signs of wear. Regular inspections are necessary to catch any potential issues early.

Proper maintenance can significantly extend the life of galvanized steel. Cleaning the surface to remove dirt and chemicals is crucial. A simple wash with soap and water may suffice. It’s essential to avoid abrasive cleaners that can damage the protective layer. If scratches occur, touch-up coatings can help restore its longevity.

Some projects expose galvanized steel to harsh conditions. High humidity, saltwater, or industrial environments can accelerate corrosion. While galvanized steel boasts durability, awareness of its limitations is key. Regular monitoring and maintenance can prevent failures, ensuring the material serves its purpose effectively.