Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

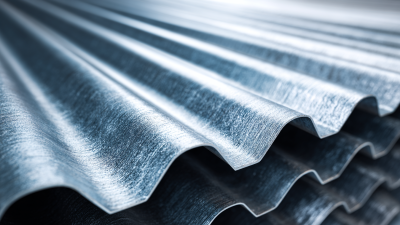

Choosing the right Gi Steel Sheet is crucial for any construction project. According to industry expert, John Hunter, "The right Gi Steel Sheet can make or break your project." Understanding your specific needs is essential.

Gi Steel Sheets are widely used due to their durability and corrosion resistance. However, not all sheets are created equal. There are many grades and coatings available. Factors such as thickness, weight, and application type should guide your choice. Yet, many overlook these details, leading to material mismatch and project delays.

Reflecting on common mistakes can improve decision-making. Often, buyers focus solely on price, neglecting important attributes. This can result in unsatisfactory performance. Investing time in research and consultation is critical. A thoughtful approach to selecting Gi Steel Sheets enhances project success.

Gi steel sheets are essential materials in various industries, including construction and manufacturing. The term "Gi" refers to galvanized iron, which is steel coated with zinc. This coating protects the steel from corrosion, making it durable and long-lasting. According to a recent industry report, the global galvanized steel market is expected to reach over $125 billion by 2027. This highlights the increasing reliance on Gi steel for structural integrity.

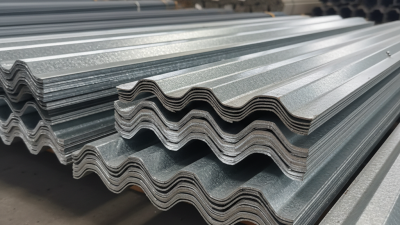

Understanding the composition of Gi steel is crucial for selecting the right sheet for your project. The thickness of the sheet, typically measured in gauge, affects its strength and suitability. A sheet of 20-gauge thickness might be appropriate for roofing, while a 16-gauge sheet can provide additional support for heavier structures. It’s important to consider these specifications. However, improper selection can lead to project delays, increased costs, and safety risks.

Moreover, while Gi sheets offer corrosion resistance, their performance can vary based on environmental factors. Humidity, temperature, and exposure to chemicals can affect durability. A study noted that 30% of galvanized products fail in extreme conditions. Thus, a thorough evaluation of the project environment is necessary. Understanding limitations can save resources, ensuring projects run smoothly.

When selecting gi steel sheets for your projects, it’s crucial to identify your specific requirements. Consider the thickness and size needed for your application. For structural support, a thicker sheet may provide the strength you require. If your project involves intricate designs, thinner sheets could be more manageable.

Assess the environment where the steel will be used. Is it exposed to moisture or extreme temperatures? These factors will influence the durability and performance of the gi steel. Corrosion resistance might become a priority if your project faces such elements. Sometimes, it is okay to admit that your initial choice may not fit perfectly.

Understanding the desired finish is also essential. A smooth surface may be needed for aesthetic projects, while a rough finish could be ideal for functional ones. It's a balancing act that may not yield immediate clarity. Keep in mind that the decision process involves trial and error. Your project’s requirements can evolve, meaning constant reassessment is key.

Each choice shapes the outcome, so reflect on your selections to minimize future regrets.

When evaluating different types of GI steel sheets, consider their thickness, coating, and tensile strength. The market offers various grades. Each grade has unique characteristics. Some are excellent for durability, while others excel in corrosion resistance. For instance, galvanized sheets commonly have a zinc coating that protects against rust. This is essential in construction projects.

Tips: Check the coating thickness. A thicker coating usually means better corrosion protection.

Different applications require different GI steel sheets. For heavy-duty industries, a sheet with higher tensile strength is critical. Reports indicate that sheets exceeding 400 MPa in strength are preferred in industrial applications. On the other hand, lighter sheets can suit household applications. Evaluating the intended use helps in making the right choice.

Tips: Assess the project requirements carefully. Misjudging the specifications could lead to costly mistakes.

Quality control is vital in this selection process. A poorly coated sheet may lead to premature failure. It’s not just about the appearance. The longevity of the product is at stake. Always source materials from reputable suppliers to reduce risks associated with low-quality products.

Choosing the right GI steel sheet involves careful consideration of thickness, weight, and durability. Thickness affects not just strength but flexibility as well. A thicker sheet can handle heavy loads but may also increase weight, making installation trickier. It’s crucial to balance strength with practicality, especially if the project has tight space constraints.

Weight is another important factor. A lightweight sheet is easier to handle and transport, yet it may compromise on durability. Projects requiring longevity should lean toward heavier options. However, think about how weight affects the overall design and application. Sometimes, opting for a heavier sheet leads to unexpected challenges.

Durability often hinges on the environment. If your project is exposed to corrosive substances, you might require a specific gauge. Think about the long-term implications. A less durable sheet could lead to early deterioration and increased costs. However, if immediate performance is essential, a thinner sheet may suffice for short-term projects. Reflecting on these details will help you make more informed choices.

When assessing Gi steel sheets for your projects, cost and supplier reliability are critical factors. The global market for coated steel sheets, including Gi, was valued at over $70 billion in 2022 and is expected to grow steadily. Understanding the pricing trends can help companies optimize their budgets. Prices can vary based on thickness, finish, and volume. It's essential to get multiple quotes to ensure you are getting the best deal.

Supplier reliability is another crucial aspect. A recent report indicated that 30% of construction delays are due to material supply issues. Thus, choosing a trusted supplier is vital. Look for suppliers with a solid reputation and positive customer reviews. Certifications and quality assurances can serve as indicators of supplier reliability.

**Tips:** Always check previous project references. Establish clear communication with potential suppliers. This can reduce misunderstandings. Consider the supplier’s location; proximity can affect both cost and lead times. Remember, cutting corners can lead to bigger issues down the line.

| Supplier | Cost per Ton (USD) | Thickness (mm) | Width (mm) | Length (mm) | Delivery Time (Weeks) | Supplier Rating (out of 5) |

|---|---|---|---|---|---|---|

| Supplier A | 750 | 2.0 | 1000 | 2000 | 4 | 4.5 |

| Supplier B | 700 | 1.5 | 1200 | 3000 | 3 | 4.0 |

| Supplier C | 720 | 3.0 | 1500 | 2500 | 5 | 4.2 |

| Supplier D | 800 | 2.5 | 1400 | 2800 | 6 | 3.8 |

| Supplier E | 690 | 2.2 | 1300 | 2200 | 2 | 4.7 |