Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the construction industry has seen a growing demand for durable and versatile materials, with Gi Corrugated Steel Sheets emerging as a preferred choice among builders and architects. According to a report by MarketsandMarkets, the global steel market is expected to reach a valuation of over $1 trillion by 2025, driven largely by the increased use of high-strength and lightweight materials in construction projects. Gi Corrugated Steel Sheets, known for their excellent resistance to corrosion and weather elements, are leading the charge as a sustainable solution that aligns with the industry's focus on longevity and eco-friendliness.

Choosing the right Gi Corrugated Steel Sheet for your project is essential, not only for aesthetic appeal but also for structural integrity. A comprehensive study by ResearchAndMarkets indicates that the demand for corrugated steel products is projected to experience a compound annual growth rate (CAGR) of around 4.5% through 2027. Understanding factors such as gauge, profile, coating type, and application is crucial to maximizing performance and ensuring that the selected materials meet both regulatory standards and project specifications. As this industry continues to evolve, making informed decisions about Gi Corrugated Steel Sheets can significantly impact the overall success and sustainability of construction ventures.

When selecting the right Gi corrugated steel sheet for your project, it’s essential to understand the various types available on the market. Gi, or Galvanized Iron, sheets are coated with zinc to enhance their resistance to corrosion and rust. This quality makes them a preferred choice for both residential and commercial applications. The thickness of the sheet is one critical factor to consider; thicker sheets provide better durability and support, while thinner sheets might be more suitable for lightweight structures or temporary installations.

Additionally, the profile of the corrugation plays a significant role in determining the sheet's functionality. Standard profiles include sinusoidal, trapezoidal, and rectangular, each offering different strengths and aesthetic qualities. Sinusoidal sheets are often used for roofing due to their sleek appearance and effective water drainage capabilities. In contrast, trapezoidal sheets provide superior strength, making them ideal for wall cladding applications. Understanding these differences enables you to choose the right type of Gi corrugated steel sheet that meets the specific requirements of your project, ensuring both performance and longevity.

| Type of Gi Corrugated Steel Sheet | Thickness (mm) | Width (mm) | Length (mm) | Weight (kg/m²) | Common Applications |

|---|---|---|---|---|---|

| Regular Corrugated | 0.4 | 900 | 2000 | 6.5 | Sheds, roofing |

| High Strength Corrugated | 0.5 | 1000 | 2500 | 8.1 | Industrial buildings |

| Ultra-lightweight Corrugated | 0.3 | 750 | 1800 | 5.2 | Temporary structures |

| Fire-resistant Corrugated | 0.45 | 880 | 2200 | 7.4 | Fire-sensitive areas |

When selecting the right GI (galvanized iron) corrugated steel sheet for your project, assessing material strength and durability is essential. According to a report by the Metal Construction Association, galvanized steel demonstrates a tensile strength ranging typically from 300 MPa to 550 MPa, making it an excellent choice for various construction applications. This strength allows structures to withstand significant stress while also ensuring structural integrity over time.

Durability is another critical factor to consider in GI corrugated steel sheet selection. Industry studies have shown that the lifespan of galvanized steel can exceed 50 years when properly maintained, thanks to its corrosion-resistant properties. The protective zinc coating, which varies in thickness from 45 to 275 grams per square meter, significantly enhances longevity, particularly in harsh environments.

Evaluating these technical specifications against your project’s specific needs ensures not only compliance with industry standards but also long-term performance and reduced maintenance costs.

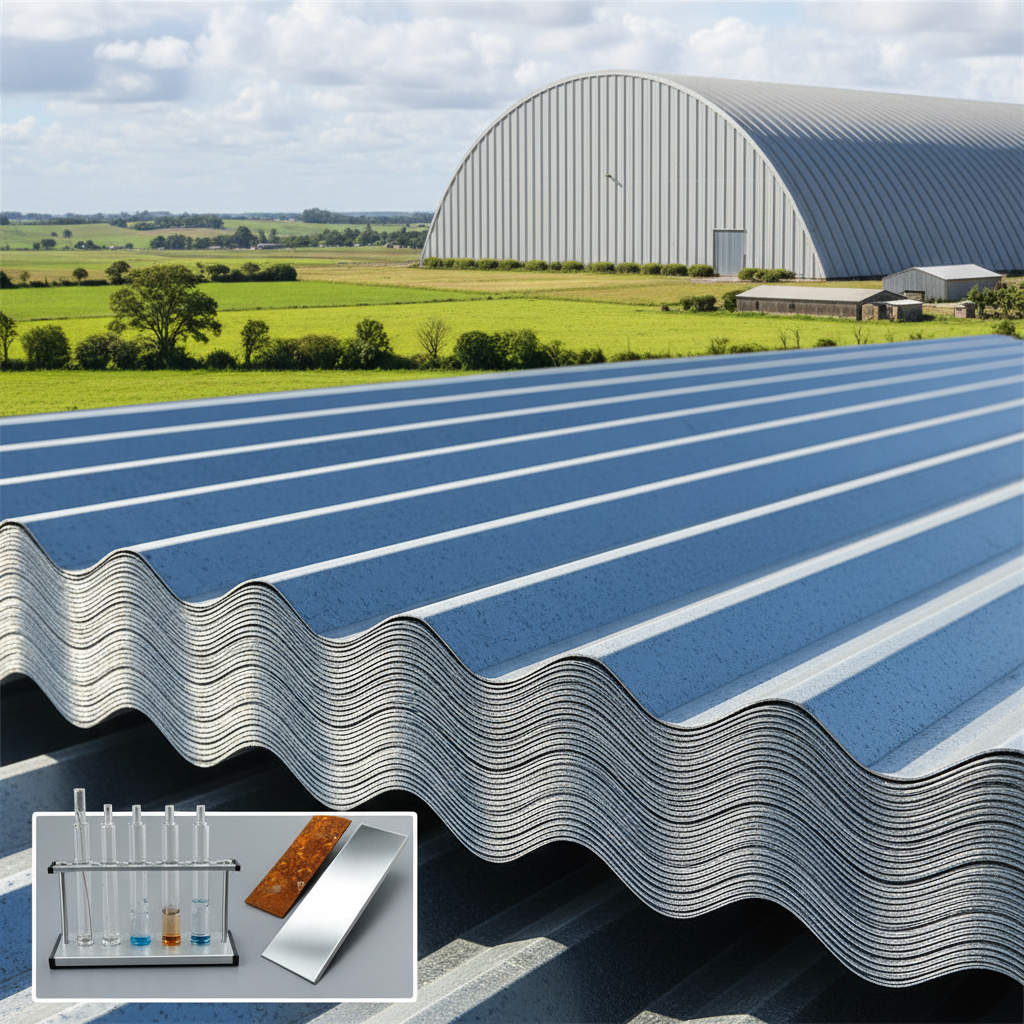

When evaluating the cost-effectiveness of various GI corrugated steel sheets, it's essential to consider both initial investment and long-term value. According to a 2022 Market Research Report, the global demand for GI corrugated steel is projected to grow by 5.6% annually, indicating a strong market confidence in its durability and versatility. One of the primary advantages of GI corrugated steel is its resistance to corrosion and adverse weather conditions, which can significantly reduce maintenance costs over time compared to other roofing materials.

Additionally, a detailed analysis from the International Steel Institute highlights that high-quality GI corrugated sheets are not only less expensive to install but also offer a lifespan exceeding 50 years with minimal upkeep. When calculating the total cost of ownership for your project, it's crucial to include factors such as energy efficiency, with numerous studies suggesting that metal roofs provide significant insulation benefits, potentially lowering heating and cooling expenses by up to 30%. By thoroughly assessing the long-term benefits in relation to upfront costs, project managers can make informed decisions that enhance both budget and sustainability.

When selecting the right GI corrugated steel sheet for your project, it's crucial to consider environmental factors that can impact both the longevity and sustainability of your materials. GI sheets, known for their durability, can contribute significantly to eco-friendly building practices if chosen wisely. One key aspect to consider is recycling capabilities; opt for products that are made from partially recycled materials.

**Tips for Choosing Environmentally Friendly GI Sheets:**

1. Look for certifications that indicate sustainability, such as those that confirm low emissions or energy-efficient manufacturing processes. Such certifications can guide you in selecting products that minimize environmental impact.

2. Evaluate the life cycle of the materials. GI sheets with longer life spans not only reduce waste but also lower the frequency of replacements, promoting a more sustainable approach to construction.

Integrating these considerations into your selection process not only enhances the environmental responsibility of your project but also ensures that the GI sheets you choose meet regulatory standards and contribute positively to the overall ecological footprint.

When selecting the right Gi corrugated steel sheet for your project, it's essential to identify the specific requirements that will guide your decision-making process. First, consider the structural integrity and load-bearing capacity needed for your application. Projects with significant weight or stress demands will require thicker sheets, while lighter applications can utilize thinner options. Additionally, assessing the environmental conditions, such as exposure to moisture or corrosive elements, will determine whether a galvanized coating or enhanced durability is necessary.

Furthermore, the aesthetic appeal and finish of the Gi steel sheet should align with the project's design vision. Different profiles and surface treatments can influence both functionality and appearance. Evaluating the scope of your project, whether it's industrial, commercial, or residential, allows you to tailor the choice of steel sheets effectively. By thoroughly understanding your project's unique specifications, you can make an informed decision that ensures both performance and longevity in your construction endeavors.