Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

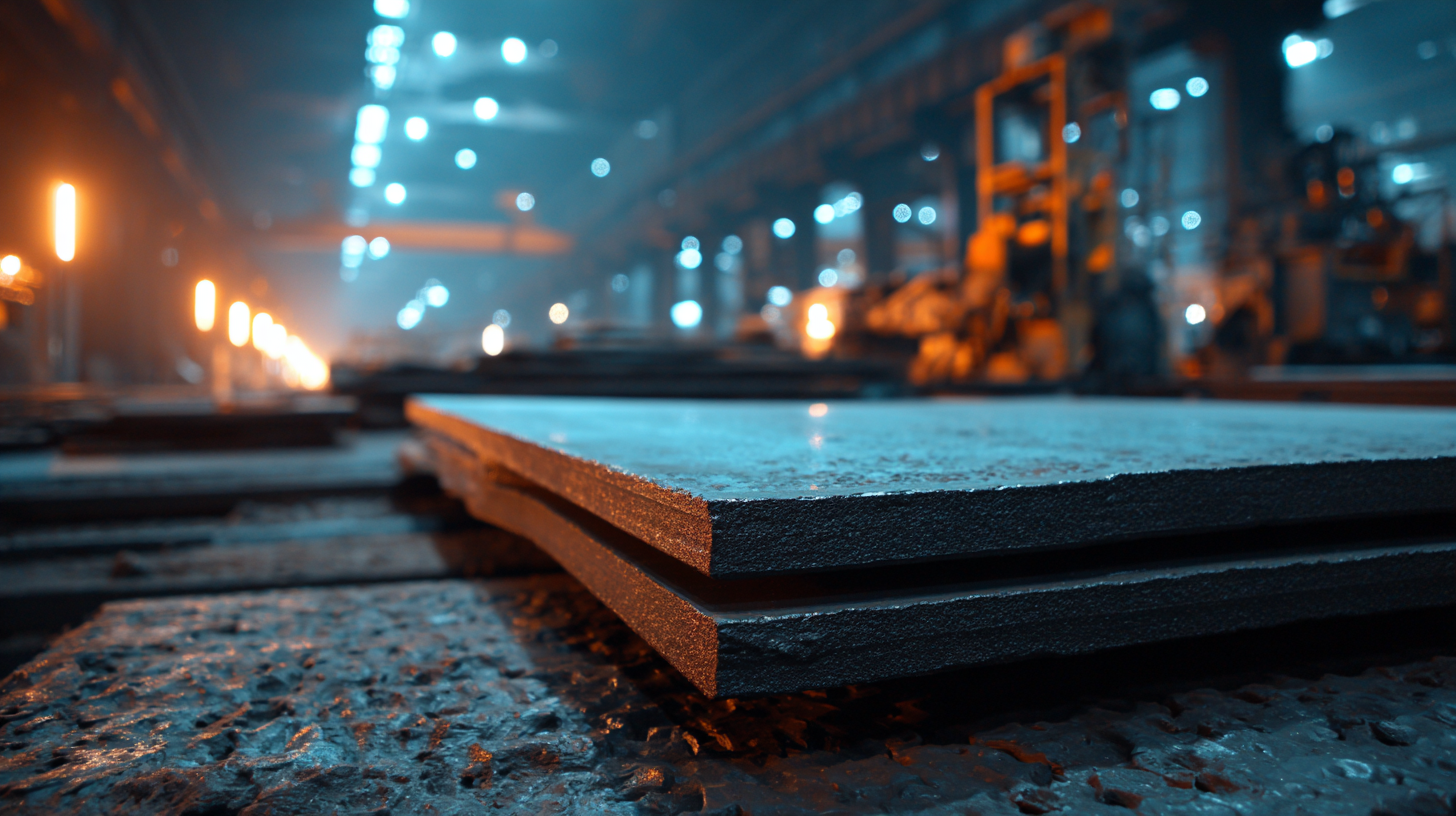

Choosing the right steel sheet for your manufacturing needs is a critical step that can significantly impact the quality, durability, and functionality of your final products. With various types, grades, and sizes available in the market, understanding the nuances of steel sheets becomes essential for manufacturers aiming to optimize their production processes. Additionally, navigating the complex landscape of industry-specific import and export certifications adds another layer of consideration that must not be overlooked. In this blog, we will explore key factors to consider when selecting the best steel sheet for your applications, ensuring that you not only meet regulatory requirements but also make informed choices that enhance your manufacturing efficiency and product performance. Whether you are involved in construction, automotive, or any other sector relying on steel sheets, this guide will equip you with the knowledge needed to make the best decisions for your business.

When it comes to selecting the best steel sheet for your manufacturing needs, understanding the different types available and their unique properties is crucial. Stainless steel sheets, for instance, are commonly categorized into various types such as 304, 316, and 310 grades. The 304 stainless steel sheet is highly versatile and resistant to corrosion, making it suitable for a wide range of applications. In contrast, the 316 grade offers enhanced resistance to pitting and is ideal for more demanding environments, such as marine applications.

When choosing the right type of steel sheet, consider the specific mechanical properties required for your project. For instance, if you need a material that can withstand higher temperatures, the 310 stainless steel sheet is known for its excellent oxidation resistance. Additionally, always assess the formability and weldability of the steel sheets to ensure compatibility with your manufacturing processes.

**Tips:** Always review the specifications of the steel sheet you're considering to ensure it meets the durability requirements for your intended application. Additionally, it's beneficial to consult with suppliers about the latest industry trends and innovations to make a more informed decision. This proactive approach can streamline your selection process and enhance the overall efficiency of your manufacturing operations.

This chart illustrates the tensile strength of different types of steel sheets commonly used in manufacturing. Understanding these properties can help you choose the best steel sheet for your specific needs.

When selecting the appropriate steel sheet for your manufacturing applications, understanding thickness and gauge is essential. The gauge of steel refers to its thickness, which can significantly affect the material's strength, durability, and flexibility. For instance, thinner sheets (higher gauge numbers) are often used for applications requiring intricate shapes, while thicker sheets (lower gauge numbers) provide more robustness for structural components.

Tips: Always refer to a gauge chart to convert measurements accurately, as the relationship between gauge number and actual thickness can vary by material type. Additionally, consider the specific requirements of your manufacturing process; for instance, laser cutting may necessitate different gauges compared to stamping.

When evaluating the right gauge for your application, think about the intended use. If your product must withstand high stress or weight, opting for a lower gauge may be best to ensure longevity and performance. Conversely, if appearance or lightweight is more important, a higher gauge can offer the necessary finesse and formability without compromising strength entirely.

| Thickness (inches) | Gauge | Standard Applications | Typical Uses |

|---|---|---|---|

| 0.012 | 30 | Lightweight applications | Automotive parts, signage |

| 0.025 | 24 | Heavy-duty applications | Equipment housings, brackets |

| 0.040 | 20 | Structural applications | Frames, panels |

| 0.058 | 16 | Heavy structural applications | Girders, embedded parts |

| 0.095 | 12 | Very heavy applications | Heavy machinery, construction components |

When selecting steel sheets for manufacturing, identifying the right grades is crucial to ensure both strength and durability. The most commonly used grades include A36, which is renowned for its structural integrity and ability to withstand various loads, making it ideal for general construction projects. On the other hand, if your application demands superior strength, consider utilizing higher-grade steel sheets such as A572 or A992, which are specifically designed for structural applications and offer enhanced resistance to bending and deformation.

Moreover, understanding the specific environmental conditions the steel sheet will be exposed to can significantly influence your choice. For instance, galvanized or stainless steel grades provide excellent corrosion resistance, which is essential in applications where moisture or chemicals are prevalent. Additionally, it's important to consider the mechanical properties of the steel grade, including yield strength and tensile strength, to ensure it meets the operational demands of your manufacturing process. By carefully assessing these factors, you can select a steel sheet that not only meets your project specifications but also guarantees longevity and performance.

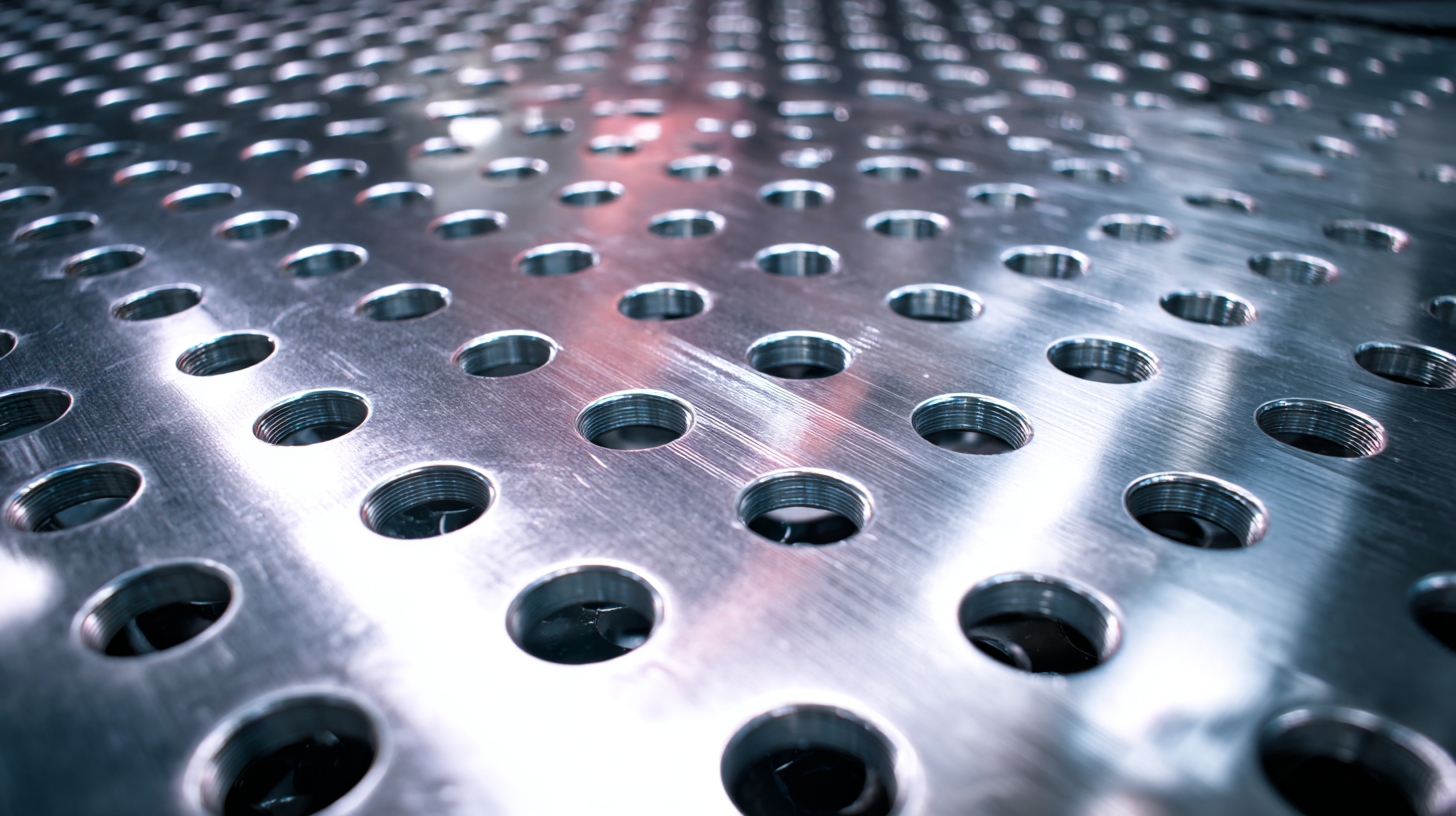

When selecting the best steel sheet for your manufacturing needs, considering

surface treatments and finishes is crucial for optimal performance. Surface modifications can

significantly impact properties such as corrosion resistance, adhesion, and overall

durability. For example, electrolytic plasma polishing (EPP)

has shown promising results in enhancing the surface quality of materials like aluminum alloys. This technique

not only improves the aesthetic appeal but also contributes to better functional performance, making it an excellent

option for applications requiring robust materials.

Tips for choosing the right surface treatment include assessing the specific requirements of your project. For

applications demanding high sensitivity and stability,

optimizing the design of microelectrodes and their surface finishes can lead to improved performance in devices

like enzymatic biosensors. It’s also essential to consider the environment in which the material

will be used, ensuring that the chosen treatment provides adequate protection against potential wear and exposure

to corrosive substances.

Another important factor is the compatibility of the surface finish with the material's intended use. Certain

finishes may be ideal for aesthetic purposes but could compromise the material's structural

integrity. Therefore, thorough testing and analysis of different treatment methods are necessary to determine

which approach will provide the best overall enhancement for your specific manufacturing needs.

When selecting steel sheets for manufacturing, finding the right balance between cost and quality is essential. A study by the American Institute of Steel Construction (AISC) indicates that high-quality steel can contribute to long-term savings by reducing maintenance costs and enhancing structural integrity. For instance, investing in higher-grade steel may lead to a decrease in the frequency of repairs and replacements, which commonly amount to 20-30% of a project’s total lifecycle cost.

However, it’s also crucial to consider the competitive advantage gained from cost-effective choices. According to a report from MarketsandMarkets, the global steel sheet market is expected to grow at a CAGR of 4.1% from 2021 to 2026, emphasizing the importance of cost management in a dynamic market. By evaluating suppliers and exploring alternatives such as recycled or locally sourced steel, manufacturers can mitigate expenses without significantly compromising quality. Thus, thorough market analysis and understanding of material specifications can empower businesses to make informed decisions, achieving the ideal balance between affordability and performance in their manufacturing processes.