Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of construction, the use of high-quality materials is paramount to ensure structural integrity and longevity. Among these materials, steel bars, also known as reinforcing bars or rebar, play a crucial role in enhancing the strength of concrete structures. According to a report by the World Steel Association, the global demand for steel bars has been increasing steadily, projected to reach 1.7 billion metric tons by 2025. This growth is indicative of their essential role in construction, particularly in high-demand markets such as infrastructure development and urbanization.

Expert opinions emphasize the importance of selecting the right type of steel bar for specific construction needs. As Dr. Emily R. Johnson, a leading materials engineer, notes, "The performance of a structure heavily relies on the quality and specifications of the steel bars used." This statement underlines the necessity for construction professionals to familiarize themselves with the top steel bar options available in the market. Understanding the characteristics of different steel bars can dramatically influence project outcomes, ensuring not only compliance with industry standards but also the safety and durability of built structures.

In light of these insights, we present a comprehensive review of the top 10 steel bars that are essential for modern construction projects. By exploring these options, professionals can make informed choices that will enhance their projects' overall performance and resilience against the test of time.

When it comes to construction projects, the selection of steel grades plays a pivotal role in ensuring the durability and longevity of structures. Different steel grades possess varying properties, such as tensile strength, corrosion resistance, and weldability. Understanding these differences is essential for engineers and architects to choose materials that can withstand environmental stresses and loading conditions specific to their projects. For example, high-strength steel grades are often preferred for high-rise buildings where load-bearing capacity is crucial, while more corrosion-resistant alloys may be necessary for marine constructions.

Moreover, the right steel grade can significantly influence the overall cost-effectiveness of a project. Using subpar materials may lead to premature failures, necessitating costly repairs or rebuilds that could have been avoided with the appropriate initial selection. Choosing high-quality steel tailored to the specific demands of the construction environment not only enhances safety but also ensures compliance with industry standards and regulations, ultimately resulting in a more reliable and enduring structure. This attention to detail in material selection is what sets successful construction projects apart.

When selecting steel bars for construction projects, understanding the fundamental differences in yield strength and tensile strength is crucial. Yield strength indicates the maximum stress a material can withstand without permanent deformation, while tensile strength reflects the maximum stress it can endure before breaking. Different types of steel bars, such as rebar and high-strength steel, exhibit varying properties that can significantly impact the durability and performance of a structure.

Recent studies, including field tests and numerical simulations, have shed light on the bonding performance of high-strength steel anti-floating anchor rods used in processes like rotary jet grouting. These investigations reveal essential data on load resistance and anchorage strength, emphasizing the importance of choosing the right steel bar type for specific construction applications. The findings underscore how advancements in steel technology contribute to improved stability and safety in construction, making it imperative for engineers and project managers to stay informed about the best steel bar options available.

When selecting steel bars for construction projects, understanding the cost-benefit ratio of different grades is crucial. High-quality steel bars, such as those classified as Grade 60 or higher, while often more expensive upfront, offer superior tensile strength and durability. According to a report by the American Institute of Steel Construction, investing in higher-grade steel can lead to a 30% reduction in long-term maintenance costs due to their increased resilience against environmental factors. Thus, while the initial investment may be higher, the long-term savings can make them a more economical choice.

Tip: When estimating project costs, always consider the life cycle of the material. Sometimes, opting for a slightly pricier option can provide significant savings over time due to lower maintenance and replacement costs.

Additionally, the steel bar's yield strength and ductility must be taken into account. For instance, Grade 40 steel may suffice for lighter structures; however, for heavy-load applications, Grade 60 or higher is recommended. The difference in performance can not only affect safety but also overall project efficiency. The World Steel Association noted that utilizing steel bars with higher grades can improve structural integrity, thereby enhancing safety measures on-site.

Tip: Research and choose suppliers who can provide detailed specifications and certifications for their steel products to ensure they meet project requirements effectively.

When it comes to construction projects, the selection of steel bars can significantly influence the long-term structural integrity of the building.

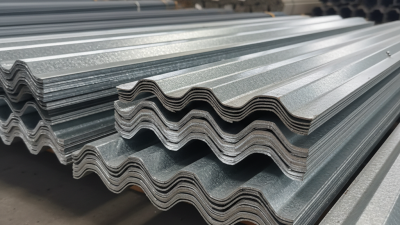

Corrosion resistance is a critical factor to consider, as it determines how well the steel will withstand environmental challenges over time. High-quality steel bars that are galvanized or made from stainless steel are often preferred for projects exposed to moisture or harsh chemicals, as they offer superior protection against rust and degradation.

Tips: Always opt for steel bars that come with a corrosion-resistance certification. It's advisable to conduct regular inspections to monitor the condition of the steel, especially in coastal areas where salt exposure can accelerate corrosion.

Furthermore, the thickness and coating of the steel bars play a crucial role in their durability. Choosing thicker bars can provide better mechanical strength, while a protective coating can enhance their longevity. Proper installation techniques, including adequate spacing and using appropriate concrete mixtures, further contribute to the overall resilience of the structure.

Tips: Consult with engineering professionals to determine the best type of steel bars for your specific project needs. Implementing preventive maintenance strategies can also extend the lifespan of structural steel elements.

Recycled steel bars are increasingly recognized for their pivotal role in promoting sustainability within construction projects. According to the World Steel Association, recycling steel reduces energy consumption by up to 74% and greenhouse gas emissions by 86% compared to producing new steel from raw materials. Utilizing recycled steel bars not only contributes to environmental conservation but also supports compliance with green building certifications like LEED. This practice resonates well with developers who are striving to meet sustainable building standards while ensuring cost-effectiveness.

When selecting steel bars for construction, prioritize materials sourced from reputable suppliers that emphasize the use of recycled steel. Tips for enhancing sustainability can include integrating local recycled steel in your projects and choosing suppliers committed to environmentally friendly practices. Additionally, monitoring the lifecycle analysis of materials can provide insights into their overall environmental impact, enabling more informed decisions on material sourcing.

Incorporating recycled steel bars helps reduce the strain on natural resources while fostering a circular economy. The American Institute of Steel Construction reports that using recycled content not only minimizes waste but also supports the economy by creating jobs in the recycling and manufacturing sectors. Thus, embracing recycled steel bars in construction is a practical approach to building a sustainable future.