Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When it comes to construction, selecting the right materials is crucial for ensuring durability and performance. Among various options available, HR steel sheets stand out as a versatile and robust choice for a wide range of applications. HR steel sheets, or hot-rolled steel sheets, are known for their excellent strength-to-weight ratio, making them ideal for structures that require resilience without the added bulk. Their unique properties allow them to be easily manipulated and formed into different shapes, catering to various construction needs.

In this article, we will explore the best types of HR steel sheets tailored for different construction projects, emphasizing their specifications, benefits, and recommended applications. From commercial buildings to residential constructions, understanding the various grades and finishes of HR steel sheets can help builders and architects make informed decisions. By diving into the characteristics and advantages of these sheets, we aim to provide valuable insights that can guide your material selection process and enhance the overall quality of your construction endeavors.

When selecting HR (Hot Rolled) steel sheets for construction projects, it's essential to understand the different types available and their unique properties. Various grades of HR steel sheets are designed for specific applications, offering benefits based on thickness, yield strength, and ductility. For instance, sheets with higher carbon content provide enhanced strength and hardness, making them suitable for heavy-duty structures. Meanwhile, lower carbon grades are more malleable, allowing for intricate designs and applications in areas where flexibility is needed.

Tips: Consider the environment in which the steel will be used. If the construction site is exposed to corrosive elements, opting for a coated or treated HR steel sheet can significantly extend the material's lifespan. Additionally, ensure that you select the appropriate thickness based on load requirements; thicker sheets can bear more weight but may also increase material costs.

Another important factor to consider is the manufacturing process of the steel sheets. Different rolling techniques yield varied surface finishes and tolerance levels. For instance, sheets produced through controlled rolling exhibit improved mechanical properties and dimensional accuracy, making them ideal for precise engineering applications. Understanding how these properties affect your project's specific needs will help you choose the right type of HR steel sheet for optimal performance and durability.

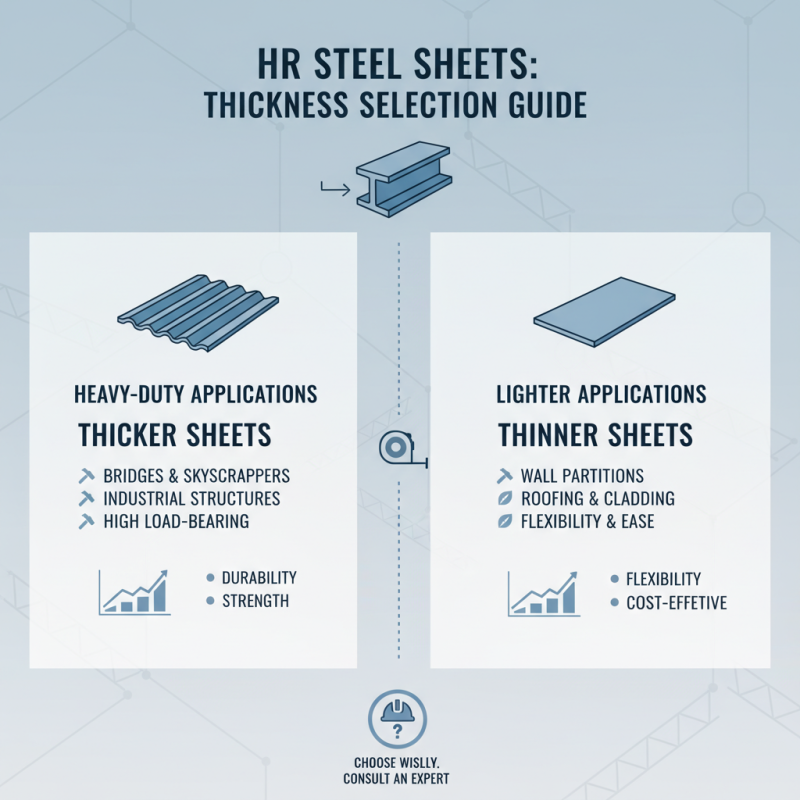

When choosing hot rolled (HR) steel sheets for construction, several factors are essential to ensure that you select the right product for your specific needs. One crucial aspect to consider is the thickness of the steel sheet, as it directly influences durability and load-bearing capacity. For heavy-duty applications, opting for thicker sheets can provide better support and structural integrity. Conversely, for lighter installations or where flexibility is required, thinner sheets may suffice.

Another important factor is the sheet's surface finish. HR steel sheets often come with mill scale, which may be acceptable in some applications, but for others, a clean surface might be necessary, especially if the steel is to be painted or welded. Additionally, it's vital to consider the environmental conditions of the site's location. If the construction project is in a corrosive environment, selecting coated HR steel sheets can enhance longevity and reduce maintenance costs.

Tips:

1. Always check specifications and standards relevant to your project to ensure compliance with safety and structural performance.

2. Consult with a steel supplier for additional insights regarding the best HR steel sheet options tailored to your project's demands.

3. Consider future modifications or extensions that may require modifications to the steel sheets, ensuring flexibility in your choice.

Hot-rolled (HR) steel sheets are vital materials used extensively across various construction projects due to their robust properties and versatile applications. According to a report by the Steel Construction Institute, hot-rolled steel is favored for its high strength-to-weight ratio, making it an ideal option for structural components in buildings, bridges, and other infrastructure. The manufacturing process of HR steel sheets enables them to achieve thicknesses ranging from 1.5mm to 25mm, supporting a wide array of construction needs, including beams, columns, and the frame structures of residential and commercial buildings.

Moreover, HR steel sheets are increasingly utilized in the fabrication of metal cladding, roofing, and siding materials, which enhance both the aesthetic and functional aspects of construction. The research published in the Journal of Construction and Steel Research highlights that the use of hot-rolled steel in roofing can significantly lower maintenance costs and improve durability when compared to traditional materials. As the construction industry continues to embrace sustainable practices, the recyclability of HR steel further solidifies its status as a preferred choice, contributing to reduced environmental impact while maintaining structural integrity in diverse applications.

HR steel sheets, or hot-rolled steel sheets, are increasingly favored in building construction due to their unique advantages. One of the primary benefits is their enhanced ductility, which allows for better shaping and formability. This is crucial in construction, where materials often need to adapt to specific structural designs. Additionally, HR steel sheets exhibit excellent weldability, making them ideal for creating strong joints in steel frameworks without compromising structural integrity.

Tip: When selecting HR steel sheets for your project, consider the sheet thickness relative to your building needs. Thicker sheets offer greater strength, while thinner sheets can provide flexibility in designs.

Another advantage of using HR steel sheets is their cost-effectiveness. They are readily available and tend to be less expensive than other forms of steel, allowing builders to optimize their budgets without sacrificing quality. Furthermore, HR steel's resistance to deformation under load means structures can be constructed to endure various environmental stresses, from wind to seismic activity.

Tip: Always evaluate the environmental factors your construction will face, as this can influence the type and thickness of HR steel sheets you choose. Proper selection ensures the longevity and safety of your building.

In the realm of construction, the choice of materials is crucial for ensuring the longevity and performance of structures. Hot Rolled (HR) steel sheets are increasingly preferred due to their superior maintenance and durability characteristics. Reports from the World Steel Association highlight that HR steel sheets exhibit excellent resistance to corrosion when adequately coated, making them suitable for harsh construction environments. The typical lifespan of HR steel structures can extend up to 30 years or more, significantly reducing the need for frequent replacement and extensive maintenance.

Maintenance practices play a vital role in enhancing the durability of HR steel sheets. Regular inspections and timely maintenance can identify potential issues, such as rust formation or surface degradation, before they evolve into significant problems. According to a recent study published by the American Iron and Steel Institute, implementing a routine maintenance schedule can increase the lifespan of steel materials by up to 50%. Furthermore, using protective coatings and galvanization techniques can bolster the steel's resistance against environmental factors, ensuring that HR steel sheets remain structurally sound and visually appealing throughout their service life. This proactive approach is essential for construction projects aiming to balance aesthetic considerations with functional reliability.

This chart represents the maintenance and durability scores of various HR steel sheet types commonly used in construction environments. The scores are based on factors such as corrosion resistance, load-bearing capacity, and impact strength.