Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Galvanized Square Pipe has become an essential material in various construction and manufacturing projects due to its exceptional durability and versatility. According to a report by Grand View Research, the demand for galvanized steel in the construction sector is expected to reach an impressive market size of $215.55 billion by 2025, highlighting the growing preference for galvanized products. This is attributed to their corrosion resistance, which significantly extends the lifespan of structures, making Galvanized Square Pipe a cost-effective choice for long-term investments.

Moreover, the use of Galvanized Square Pipe not only enhances structural integrity but also contributes to sustainable building practices. A study by the American Galvanizers Association indicates that galvanized steel can maintain its integrity even in harsh environmental conditions, reducing the need for frequent replacements and repairs. As industries shift towards eco-friendly solutions, the adoption of galvanized materials is on the rise, aligning with the global push for sustainability and efficiency in construction methodologies. This article explores the top 10 benefits of using Galvanized Square Pipe for your next project, showcasing why it stands out as a preferred solution in modern construction.

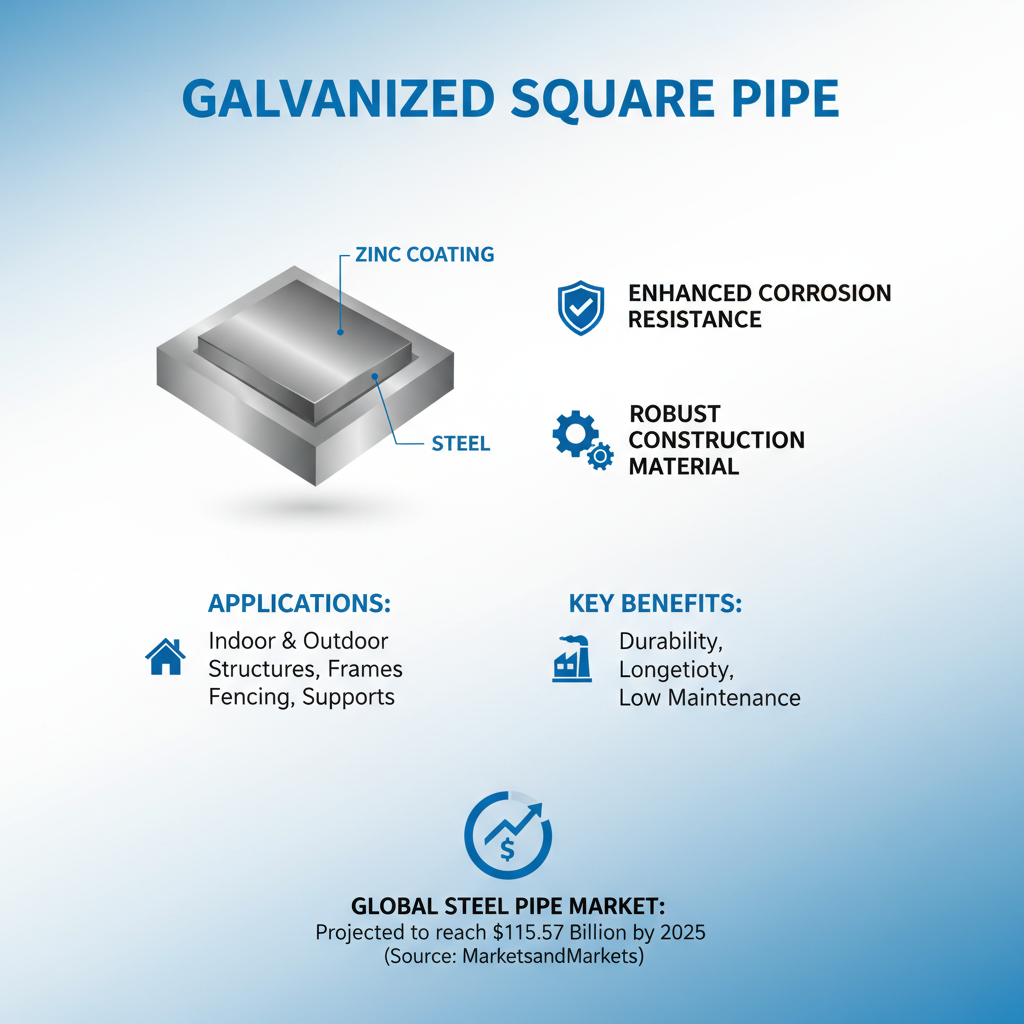

Galvanized square pipe, crafted from steel and coated with a layer of zinc, serves as a robust solution in various construction and manufacturing applications. Its primary function is to enhance the metal's resistance to corrosion, making it ideal for both indoor and outdoor environments. According to a report by MarketsandMarkets, the global steel pipe market is projected to reach $115.57 billion by 2025, driven in part by the increasing demand for galvanized products in construction due to their durability and longevity.

One of the notable advantages of using galvanized square pipe is its structural strength. Data from the American Institute of Steel Construction demonstrates that galvanized piping not only meets but often exceeds the strength standards required for commercial and industrial applications. Additionally, the zinc coating significantly reduces maintenance costs over the lifespan of the product, which can lower overall project expenses. This cost-effectiveness, coupled with the pipe’s ability to withstand adverse environmental conditions, highlights its role as an essential component in contemporary construction projects.

Galvanized square pipe offers remarkable durability and corrosion resistance, making it an exceptional choice for various construction and industrial applications. The hot-dip galvanization process significantly enhances the longevity of steel, with a protective zinc layer that shields it from harsh environmental factors. According to recent reports, the global galvanized steel market was valued at approximately USD 241.87 billion in 2024 and is projected to reach about USD 353.51 billion by 2030, showcasing a substantial growth trend driven largely by the increasing demand for durable construction materials.

Furthermore, the importance of corrosion resistance in infrastructure cannot be understated, especially in challenging environments like wastewater treatment facilities. A review of corrosion assessment and mitigation techniques highlights that robust monitoring and inhibition strategies are essential to prevent structural degradation. As a result, projects utilizing galvanized square pipe benefit not only from enhanced safety and longevity but also from reduced maintenance costs, which are critical factors in industry planning. With significant growth predicted in the galvanized rigid conduit market, expected to rise from USD 798.2 million in 2024 to around USD 1.4 billion by 2034, the choice of galvanized square pipe aligns perfectly with current and future industry needs.

This chart illustrates the key benefits of using galvanized square pipe for various projects, emphasizing its durability and corrosion resistance compared to other materials.

When considering materials for your next construction project,

cost-effectiveness is often at the forefront of decision-making.

Galvanized square pipes are a wise choice, primarily due to their

economical benefits. According to a report by the American Iron and Steel Institute, galvanized steel can

provide significant savings over the lifetime of a project compared to non-galvanized alternatives.

The durability provided by the zinc coating ensures that these pipes resist rust and corrosion,

leading to lower maintenance and replacement costs. It has been shown that facilities using galvanized piping

experience up to a 33% reduction in maintenance expenses, enhancing overall

budget efficiency.

Furthermore, the initial cost of galvanized square pipes is competitive. A study conducted by the Steel Market Development Institute found that the price of galvanized steel

often remains lower than that of stainless steel and other alternatives, ranging from

10-30% less in some cases. These savings, combined with their longevity, make

galvanized square pipes not just a cost-effective option, but also a fiscally responsible investment in any project.

Opting for galvanized piping not only benefits your budget but also supports sustainable practices by

reducing waste from more frequent replacements.

Galvanized square pipes offer remarkable versatility, making them suitable for a wide range of applications. These pipes are commonly employed in structural frameworks, fences, and agricultural equipment due to their strength and resistance to corrosion. Their elegant aesthetic also makes them a popular choice for decorative projects, such as railings and modern furniture. In industries like construction and manufacturing, galvanized square pipes serve as key components in scaffolding and support systems, proving their functional and aesthetic adaptability in various settings.

**Tip:** When selecting galvanized square pipes for your project, consider the specific environmental conditions they will face. For instance, outdoor applications may require heavier galvanization to enhance durability against the elements.

In addition to structural uses, galvanized square pipes are excellent for pipe supports and hangers in plumbing systems. Their uniform shape allows for easy installation and adjustment, making them advantageous for both residential and commercial plumbing needs. Emphasizing their lightweight nature, these pipes simplify transportation and handling on job sites.

**Tip:** Always double-check the weight capacity of galvanized square pipes for structural use to ensure they meet the requirements of your project.

| Benefit | Description | Applications |

|---|---|---|

| Corrosion Resistance | Galvanization provides a protective layer against rust and corrosion. | Outdoor structures, fences, and utility poles. |

| Strength | High tensile strength makes it ideal for structural support. | Building frames, scaffolding, and heavy-duty construction. |

| Versatility | Can be used in various applications across multiple industries. | Automotive, furniture, and agricultural equipment. |

| Ease of Welding | Weldable properties allow for easy assembly and modification. | Custom fabrication for structures and decorative pieces. |

| Cost-Effectiveness | Lower maintenance and longer lifespan reduces overall costs. | Commercial buildings, industrial applications, and housing. |

| Lightweight | Easier to handle and transport than heavier materials. | Shipping structures and portable applications. |

| Aesthetic Appeal | Smooth finish provides a clean and modern look. | Architectural designs and decorative railings. |

| Recyclability | 100% recyclable, supporting sustainable practices. | Green building projects and environment-friendly constructions. |

| Thermal Conductivity | Good conductor of heat; useful in various applications. | Heat exchangers and HVAC systems. |

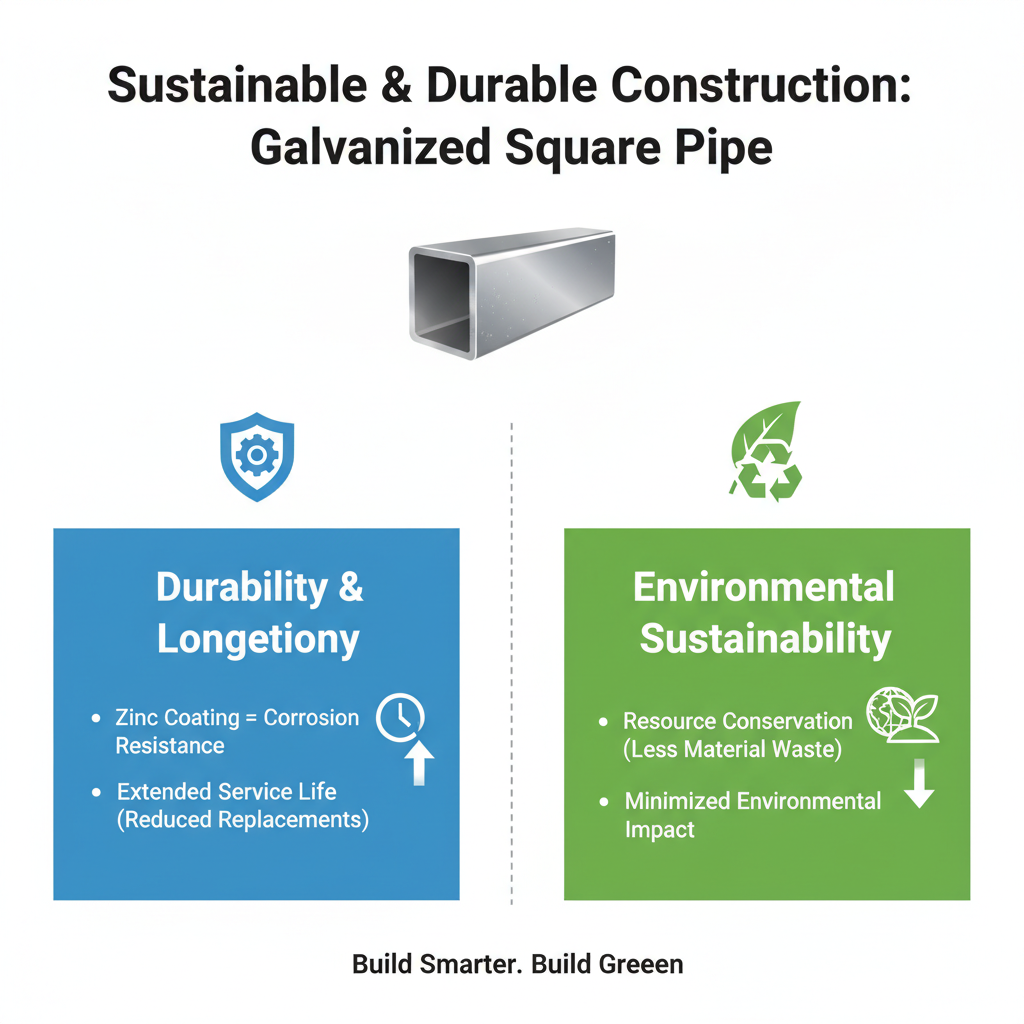

When considering materials for construction projects, galvanized square pipe stands out not only for its durability but also for its environmental sustainability. Galvanization, the process of coating steel pipes with a protective layer of zinc, enhances the longevity of the material, thereby reducing the need for frequent replacements. This not only conserves natural resources but also minimizes waste, contributing positively to environmental conservation efforts.

Tips for reducing your project's ecological footprint include choosing galvanized materials that are made from recycled steel, which further lowers energy consumption and reduces greenhouse emissions during production. Additionally, ensure proper disposal or recycling of leftover galvanized pipes at the end of their life cycle, as they can be repurposed, contributing to a circular economy.

Moreover, utilizing galvanized square pipe can lead to energy savings in the long run. Its resistance to corrosion means that structures remain intact and efficient over time, leading to less frequent maintenance. This contributes to the overall sustainability of your project, as it conserves both financial and environmental resources while maintaining structural integrity.