Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the fast-evolving construction and manufacturing industries, "Galvanized Coils" play a pivotal role. Industry expert John Smith once stated, “Galvanized Coils are not just about protection; they define durability.” His words underscore the critical importance of these materials.

Galvanized Coils are created through a process that coats steel with zinc. This process enhances resistance to corrosion, making it ideal for various applications. Their usage significantly reduces maintenance costs and increases the lifespan of products. For example, in automotive manufacturing, Galvanized Coils help create rust-resistant car bodies. This leads to safer, longer-lasting vehicles.

However, there are challenges. The production quality of Galvanized Coils can vary widely. Not every manufacturer meets the highest standards. This inconsistency can result in premature failure of the coated surfaces. It's crucial for buyers to carefully evaluate suppliers and product specifications. The benefits of Galvanized Coils are undeniable, but awareness of potential pitfalls is essential.

Galvanized coils are essential materials in various industries. They consist of steel coated with zinc. This coating provides a protective layer, preventing rust and corrosion. The process of galvanization enhances the steel's durability. This makes it suitable for both indoor and outdoor applications.

Understanding the composition of galvanized coils is crucial. The zinc coating typically ranges from 40 to 300 grams per square meter. This variation depends on the intended use. Thicker coatings offer better protection but can be costlier. Conversely, thinner coatings reduce expenses, yet may wear out faster. It's a trade-off that businesses need to consider.

Tips: When selecting galvanized coils, consider the environment they will be exposed to. Harsh climates may require thicker coatings. Regular inspections can catch wear early. Also, think about the manufacturing process. Some methods may yield better adhesion between zinc and steel. This can impact the longevity of the galvanized coil. Remember, the right choice today can save costs tomorrow.

Galvanized coils offer significant advantages, particularly when it comes to corrosion resistance. The zinc coating on these coils creates a protective barrier that prevents rust. This feature is crucial for industries that face harsh environments. For instance, construction materials exposed to moisture or chemicals remain intact for longer periods. The longevity of galvanized coils makes them a cost-effective choice over time.

Another benefit is the adaptability of galvanized coils. They can be used in various applications, from automotive manufacturing to HVAC systems. Their versatility helps industries address specific needs. Despite these benefits, there are limitations to consider. When subjected to extreme temperatures, the zinc layer might degrade. This can reduce the effectiveness of corrosion protection. Users must assess the environment where these coils will be utilized. Regular inspections and maintenance may be necessary to ensure performance. Ultimately, galvanized coils present a compelling option for many applications, though careful consideration of their limitations is essential.

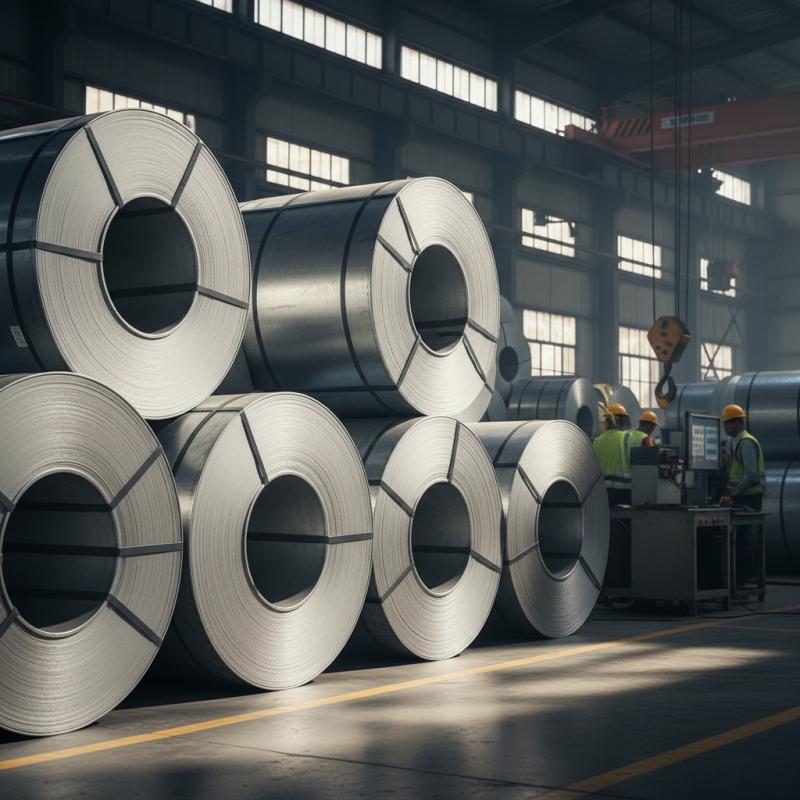

Galvanized coils are widely used in many industries due to their cost-effectiveness. The process of galvanization involves coating steel with zinc, which prevents rust and corrosion. This can substantially extend the lifespan of products, reducing replacement costs over time. In sectors like construction, these coils are integral. They are used in roofing materials, gutters, and structural components.

The versatility of galvanized coils is a game-changer. They are lightweight yet strong, making them suitable for numerous applications. The automotive industry benefits as well. Car manufacturers utilize these coils to enhance durability while keeping production costs manageable. However, it’s crucial to consider the environmental impact of zinc mining. Sustainable practices are necessary to mitigate negative consequences.

While galvanized coils offer great cost benefits, there are limitations. The protective layer may wear off over time, exposing the steel underneath. Regular maintenance is key to preserving their advantages. Industries must balance the benefits with the potential downsides. Choosing the right application and proper care can lead to substantial savings and effective use.

Galvanized coils are crucial in various construction and manufacturing applications. Their durability is a major reason they are widely used. According to a report from the World Steel Association, galvanized steel has a lifespan that can exceed 50 years in many environments. This long-lasting quality makes it an ideal choice for structural components.

In construction, galvanized coils are often employed for roofing, siding, and structural support. They resist rust and corrosion, which is vital when exposed to harsh weather conditions. Data shows that using galvanized steel can reduce maintenance costs by up to 50%. This is significant for long-term projects. However, it is important to ensure proper coating thickness, as insufficient thickness may lead to premature rusting.

In manufacturing, galvanized coils are used in appliances and automotive parts. These products often face exposure to moisture and chemicals. The protective layer of zinc helps to maintain their integrity. Reports indicate that the automotive industry, for instance, relies heavily on galvanized components to enhance vehicle longevity. Yet, manufacturers sometimes overlook the importance of selecting the right grade of galvanized steel for specific applications.

Galvanized coils are increasingly recognized for their sustainability. They are made by coating steel with zinc. This process adds a protective layer, enhancing durability. The longer lifespan means fewer replacements are needed. This reduces waste and conserves resources.

Using galvanized materials can lower environmental impact. The production of galvanized steel emits fewer pollutants compared to many alternatives. Zinc is abundant and can be recycled easily. This means that choosing galvanized coils contributes to a circular economy. However, one must consider energy consumption during the galvanization process. There are energy costs to weigh against benefits.

The longevity of galvanized coils is commendable. They resist corrosion, even in harsh environments. However, one must scrutinize sourcing and processing methods. Local sourcing can reduce transportation emissions. Overall, galvanized coils offer clear advantages for sustainable construction and manufacturing, but challenges remain in ensuring responsible production practices.