Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

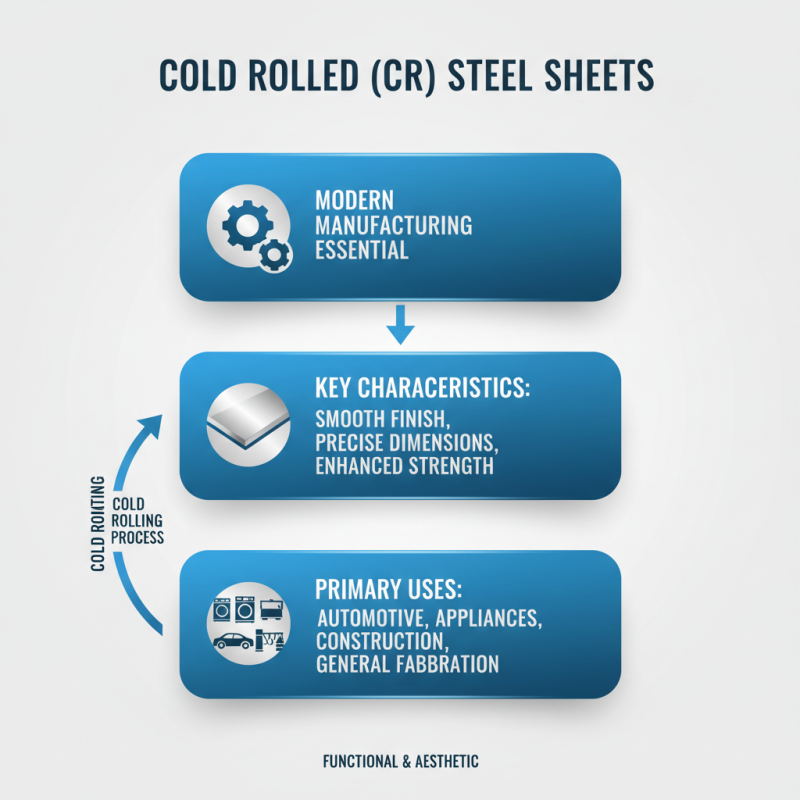

In the evolving landscape of manufacturing, CR steel sheets stand out for their versatility and durability. Renowned expert Dr. Emily Turner remarks, "The right CR steel sheet can make all the difference in production quality." This highlights the importance of selecting the best materials for various applications.

CR steel sheets are crucial in automotive, construction, and appliance industries. Their ability to withstand harsh conditions makes them a preferred choice. Many manufacturers face challenges in choosing the right type and grade of CR steel sheet. Finding a balance between cost and performance can be daunting.

Every application demands specific features from CR steel sheets. Some sheets are designed for strength, while others focus on corrosion resistance. It’s essential to understand these requirements to make informed decisions. As industries evolve, so too must the materials they utilize, reflecting on the choices made today.

Cold rolled (CR) steel sheets are essential in modern manufacturing. Their smooth finish and precise dimensions make them ideal for various applications. The cold rolling process enhances strength and surface quality. Many industries rely on CR steel for both functional and aesthetic purposes.

These sheets are widely used in automotive, construction, and appliance industries. They serve as crucial components in vehicle frames, metal furniture, and cabinets. The uniform thickness of CR steel ensures safety and reliability. However, the production process can lead to quality inconsistencies sometimes overlooked.

Understanding the importance of CR steel sheets helps in making informed choices. Their versatility is impressive, yet buyers must consider factors like corrosion resistance and workability. Balancing these features and potential drawbacks is key for successful applications in diverse fields. Choosing the right type of CR steel is not always straightforward, but careful consideration is necessary.

When choosing the best CR steel sheets in 2026, several key features stand out. High corrosion resistance is essential. This feature ensures longevity in various environments. According to a recent industry report, CR steel sheets with premium coatings can increase their lifespan by up to 30%. Thickness also plays a role; sheets ranging from 0.3 mm to 3 mm are commonly preferred for their versatility.

Surface finish is another critical aspect. A smooth, uniform finish not only improves aesthetics but also enhances functionality. Many industries, from automotive to construction, value sheets that minimize surface imperfections. Studies indicate that sheets with better surface quality can result in lower maintenance costs over time.

**Tips:** Always assess the sheet’s properties against your project's specific requirements. Consult with technical experts for optimal results. Additionally, understanding the environmental conditions is vital. The right type of CR steel can prevent unexpected failures, which could be costly.

When choosing CR steel sheets, it’s important to understand the different types available. There are mainly two categories: cold-rolled and hot-rolled sheets. Cold-rolled sheets are known for their smooth surface. They are ideal for applications requiring precise dimensions. In contrast, hot-rolled sheets are thicker. They tend to be less expensive but may have a rougher finish. Choosing between them depends on the end use.

Thickness is another vital aspect. Common thicknesses range from 0.3 mm to 3 mm. Thinner sheets are preferred for applications like appliances and automotive parts. They allow for easy shaping and bending. On the other hand, thicker sheets provide more strength. This makes them suitable for structural applications. However, thicker sheets can be harder to work with and may require specialized tools.

Understanding the coating options also plays a crucial role. Electrolytic galvanization offers corrosion resistance, while uncoated sheets are more exposed to elements. This choice can significantly affect durability and maintenance. Each type has its advantages and drawbacks. It requires careful consideration based on the project requirements. Evaluating these factors may feel overwhelming, but it's vital for making the right choice.

Cold-rolled (CR) steel sheets find widespread use across various industries due to their excellent surface finish and mechanical properties. The automotive sector relies heavily on CR sheets for body panels, structural components, and chassis. According to industry reports, nearly 40% of automotive steel is now CR steel. This demand is driven by the need for lightweight materials that enhance fuel efficiency while maintaining strength.

In construction, CR steel sheets are crucial for both functional and aesthetic applications. They are utilized in roofing, siding, and interior walls. A report by the World Steel Association indicates that the construction sector accounts for 15% of global CR steel consumption. The durability and formability of these sheets make them ideal for a variety of building designs.

However, challenges exist in the market. The high production cost of CR steel sheets can limit their usage in budget-sensitive projects. Additionally, the environmental impact of steel production raises questions about sustainability. Efforts to reduce emissions and promote recycling within the industry are ongoing. As the market evolves, adaptability and innovation will play key roles in addressing these issues.

| Feature | Type | Common Applications | Industry |

|---|---|---|---|

| High corrosion resistance | Cold Rolled Steel Sheet | Automotive panels | Automotive |

| Excellent surface finish | CR Steel | Home appliances | Manufacturing |

| Formability | Low Carbon Steel | Furniture | Furniture |

| Lightweight | Electro-Galvanized Steel | Building structures | Construction |

| Eco-friendly | Recycled Steel Sheet | Packaging | Packaging |

The future of CR steel sheet manufacturing is poised for exciting innovations. Industry trends indicate a growing focus on sustainability. Reports show that nearly 40% of steel production now aims to reduce carbon emissions. Techniques like electric arc furnace (EAF) production are becoming increasingly prevalent. This transition can decrease carbon footprints significantly. Moreover, efficiency in manufacturing is being prioritized. The push is for automation and AI integration, optimizing quality control and reducing waste.

Another critical area is material research. Emerging alloys and treatments improve strength-to-weight ratios. Data suggests that the market for high-strength low-alloy (HSLA) steel could grow by 5% annually. Yet, challenges remain. Adapting production systems for new materials can be costly. Companies must brace for potential disruptions. The global nature of supply chains can complicate matters.

Lastly, customer demands are shifting. There is an increased need for customization. Manufacturers must find ways to meet these diverse market needs efficiently.