Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

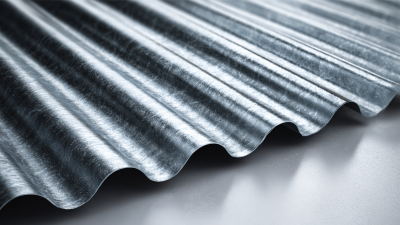

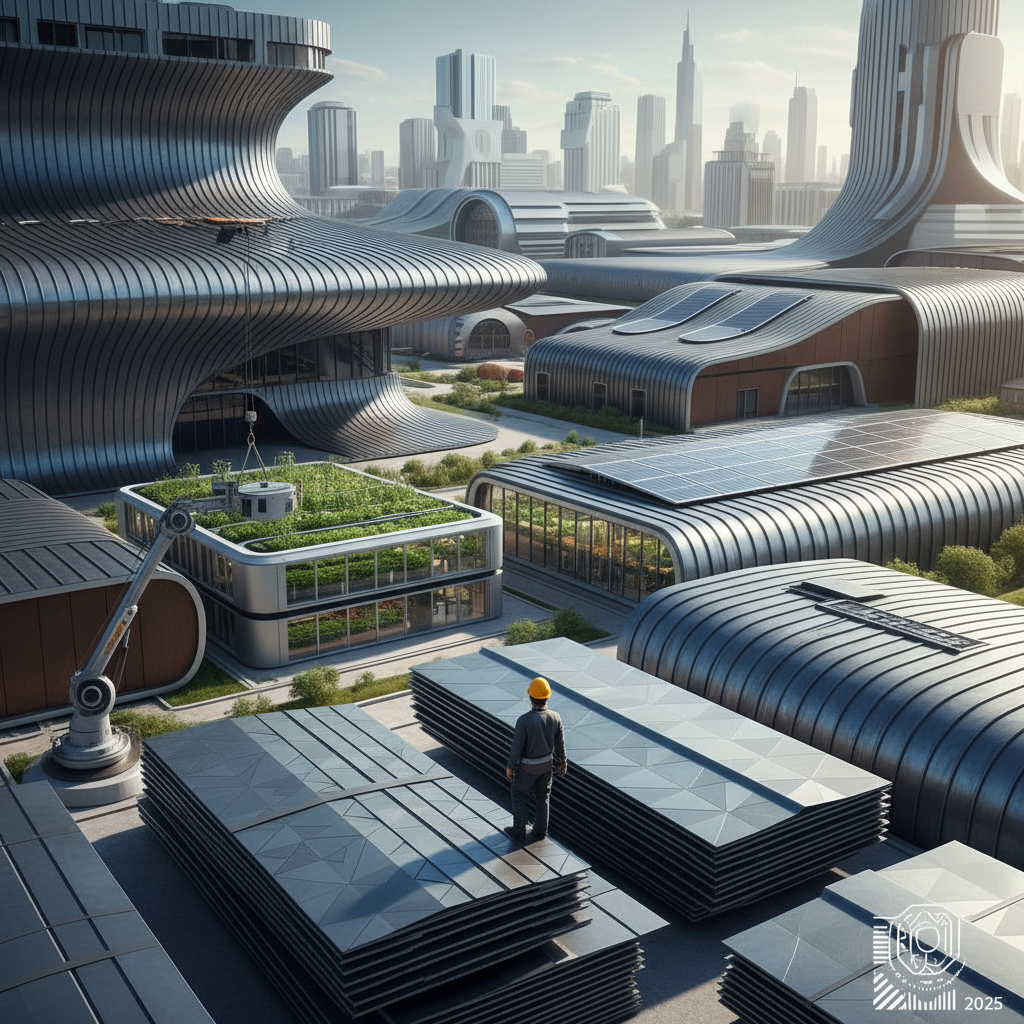

As we move into 2025, the landscape of the construction and manufacturing industries is being reshaped by the innovative application of Gi Corrugated Steel Sheets. These materials are not only pivotal in enhancing structural integrity and durability but are also becoming increasingly popular due to their eco-friendliness and cost-effectiveness. According to a recent report by MarketsandMarkets, the global market for G.I. sheets is expected to grow at a CAGR of 5.7% from 2023 to 2028, driven by rising infrastructure projects and the need for sustainable building materials.

Industry expert Dr. Emily Kang, a noted authority in steel technology, emphasizes the significance of these advancements, stating, “The evolution of Gi Corrugated Steel Sheet technology is revolutionizing how we approach construction, making buildings safer and more efficient.” In 2025, the trends will showcase innovations that leverage smart manufacturing processes and enhanced coating techniques, ensuring longevity and reducing maintenance costs for end-users. The applications of Gi Corrugated Steel Sheets are vast and will continue to expand across various sectors, including residential, commercial, and agricultural developments, shaping the future of infrastructure on a global scale.

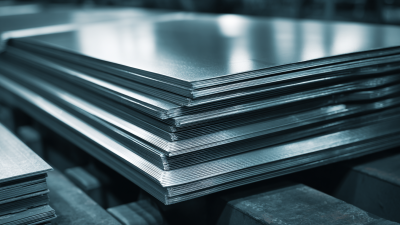

The manufacturing sector of GI corrugated steel sheets is poised for transformative changes in 2025, driven by emerging technologies that enhance efficiency and sustainability. Innovations such as automated production lines, advanced coating techniques, and AI-driven quality control systems are expected to significantly reduce production costs while improving product durability. According to a recent industry report by MarketsandMarkets, the global demand for corrugated steel sheets is projected to grow at a CAGR of 6.4% from 2023 to 2028, highlighting the increasing need for advanced manufacturing technologies.

**Tips:** As manufacturers consider integrating these technologies, they should focus on adopting smart manufacturing practices. Implementing IoT devices can streamline operations and provide real-time data analytics, which can help in predictive maintenance and reduce downtime.

Additionally, advancements in eco-friendly coating technologies are leading to the development of GI corrugated steel sheets with enhanced corrosion resistance and lower environmental impact. Innovations such as organic coatings and nanomaterials not only improve the longevity of these products but also align with the growing demand for sustainable construction materials. As stated by the World Steel Association, the steel industry can potentially reduce its carbon footprint by up to 20% with these modern manufacturing techniques, making sustainability a core aspect of future production practices.

**Tips:** Companies should collaborate with technology providers to identify suitable innovations that can be tailored to their manufacturing needs, ensuring they remain competitive in a rapidly evolving market.

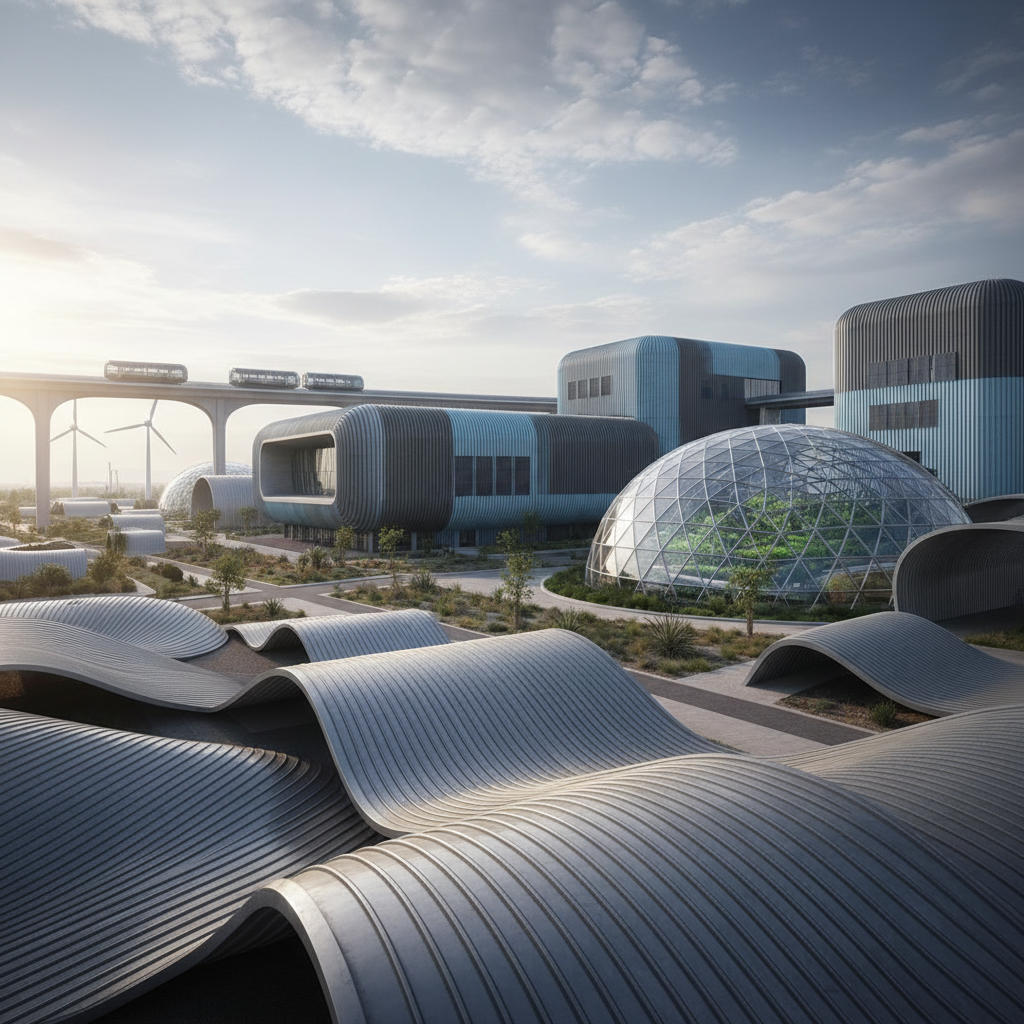

The trend towards sustainable practices in the steel industry is rapidly gaining momentum, driven by a growing demand for eco-friendly innovations in steel sheet production. With the global steel market projected to reach approximately $221.41 billion by 2031, companies are re-evaluating their production methods to minimize carbon emissions and embrace circular economy principles. This evolution not only meets regulatory standards but also positions firms as leaders in sustainability.

Tips for implementing sustainable practices in steel sheet production include investing in energy-efficient technologies and adopting rigorous carbon emission audits. Companies should also explore the use of alternative materials and processes that reduce environmental impact, such as recycled steel and greener production techniques. Furthermore, staying informed about future policies and industry guidelines is essential for adapting strategies to continually enhance sustainability efforts.

As the market evolves, steel manufacturers are expected to focus increasingly on innovation, aiming to create products that align with eco-friendly frameworks. This shift not only enhances brand reputation but also appeals to a consumer base that values sustainability, ultimately contributing to a more resilient and environmentally-conscious steel industry.

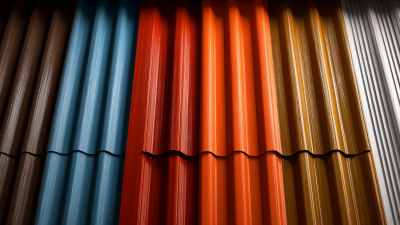

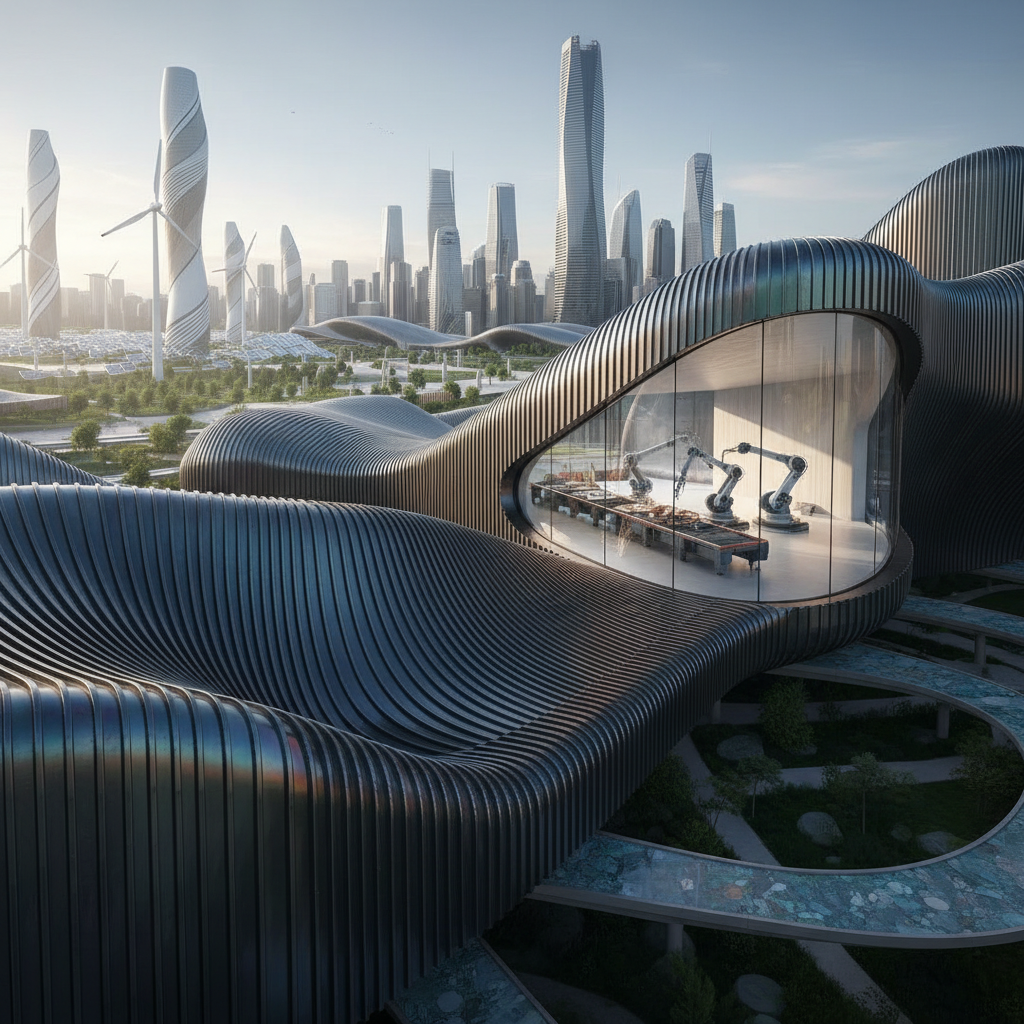

In modern architecture and construction, Gi corrugated steel sheets have emerged as vital components, showcasing their versatility and innovative applications. According to a report by Research and Markets, the global market for corrugated steel sheets is expected to grow at a CAGR of 7.2% from 2023 to 2028, fueled by urbanization and the need for sustainable building materials. These sheets are increasingly favored for their lightweight yet robust structure, making them ideal for roofing, wall cladding, and even interior design elements.

One of the key advantages of Gi corrugated steel sheets is their energy efficiency. With excellent thermal properties, they help regulate building temperatures, reducing energy costs. Additionally, they are highly resistant to environmental factors such as corrosion and impact, ensuring longevity. Architects are leveraging these attributes to create aesthetically pleasing yet functional designs, integrating Gi sheets into modern facades and commercial buildings.

Tips: When considering the use of Gi corrugated steel sheets, prioritize suppliers who offer galvanized options, as this can significantly enhance corrosion resistance. Furthermore, always check local building codes to ensure compliance with safety and sustainability standards. Lastly, incorporating insulation with these sheets can further improve energy efficiency, making your structure not only stylish but also eco-friendly.

The market for GI corrugated steel products is demonstrating a notable shift in consumer preferences, influenced by various factors such as sustainability, cost-effectiveness, and durability. As industries increasingly prioritize environmentally friendly materials, GI corrugated steel has emerged as a popular choice due to its recyclable nature and longevity. This trend is evident in both construction and packaging sectors, where the demand for lightweight yet robust materials tools into the design of innovative GI steel solutions that meet modern aesthetic and functional requirements.

In addition to sustainability, the growth in demand is being driven by rising construction activities across emerging economies. The attractive features of GI corrugated steel, including resistance to corrosion and weather, align well with the needs of developers looking for reliable materials to build enduring structures. Market analysts predict that as urbanization continues to expand, the incorporation of GI corrugated steel products will grow, further enhancing their market share and establishing them as a staple in future building and construction trends.

The Gi corrugated steel industry is poised for significant transformation in the coming years, driven by both challenges and opportunities. One of the primary challenges is the increasing demand for sustainable practices. As environmental concerns grow, manufacturers must adapt their production processes to minimize waste and reduce their carbon footprint. Embracing recycling and utilizing eco-friendly materials can not only address these challenges but also enhance the brand image of companies committed to sustainability.

On the opportunity front, the advancement of technology presents a promising avenue for growth. Innovations in coatings and treatments can improve the durability and aesthetic appeal of Gi corrugated steel sheets, expanding their applications beyond traditional uses in construction. Additionally, the rise of smart manufacturing, driven by automation and data analytics, can optimize production efficiency and open new markets for customized products. By leveraging these technological advancements, the industry can respond more effectively to changing consumer preferences and broaden its reach in diverse sectors.

In summary, the Gi corrugated steel industry stands at a crossroads of challenges and opportunities. By focusing on sustainability and embracing technological advancements, companies can not only navigate these challenges but also thrive in an evolving market.