Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right materials for your construction or DIY project is critical to ensure longevity and performance. Among the various options available in the market, the Galvanized Rectangular Pipe stands out as a versatile choice due to its unique properties. Known for its exceptional strength, durability, and corrosion resistance, this type of pipe is widely used across different industries, including construction, manufacturing, and plumbing.

As we delve into the 2025 Guide on selecting the best Galvanized Rectangular Pipe for your specific needs, we will explore key factors that influence this decision. From understanding the different sizes and thicknesses available to assessing the purpose of your project and the environmental conditions it will face, making an informed choice is essential. By the end of this guide, you will gain valuable insights that will not only enhance the quality of your project but also ensure compliance with safety standards and longevity of the installed materials.

Galvanized rectangular pipes are versatile construction materials widely used in various applications, from structural frameworks to plumbing systems. When selecting the right pipe for your project, it’s essential to understand the materials and specifications involved. Generally, galvanized pipes are made from steel coated with a layer of zinc, which enhances corrosion resistance. According to the American Iron and Steel Institute (AISI), the use of galvanized steel can increase the longevity of piping systems by up to 50% compared to non-galvanized alternatives, making it a preferred choice for both residential and industrial purposes.

Understanding the specifications of galvanized rectangular pipes is crucial in ensuring they meet your project requirements. Key specifications include wall thickness, length, and outer dimensions, which play significant roles in determining the pipe’s strength and suitability. Industry reports indicate that varying gauges are available, typically ranging from 14 to 4 gauge, correlating directly to the pipe's load-bearing capacity. Moreover, the zinc coating can differ in thickness, generally ranging from 1.0 to 3.9 ounces per square foot, which influences both durability and resistance to environmental factors. Making informed decisions based on these specifications will ensure optimal performance and longevity of your piping installations.

| Material Type | Dimension (mm) | Wall Thickness (mm) | Weight (kg/m) | Standard Specification |

|---|---|---|---|---|

| Mild Steel | 50 x 100 | 3.0 | 5.7 | ASTM A500 |

| Galvanized Steel | 75 x 150 | 4.0 | 7.2 | EN 10025 |

| High Strength Steel | 100 x 200 | 5.0 | 10.4 | ASTM A992 |

| Stainless Steel | 50 x 100 | 2.5 | 4.3 | ASTM A554 |

When selecting the right galvanized rectangular pipe for your project, several key features play a pivotal role in ensuring the pipe's suitability and durability. Firstly, assess the thickness of the pipe walls, as this directly affects the pipe's strength and resistance to corrosion. According to a report by the Galvanizers Association, thicker walls tend to have a more extended life span, particularly in environments subjected to harsh weather conditions or industrial exposures. Standard wall thickness ranges typically from 1.2mm to 3.2mm, depending on the application requirements.

Moreover, pay attention to the dimensions of the pipe. The width and height of the rectangular pipe must align with your project's design specifications. A comprehensive study by the American Institute of Steel Construction recommends matching these dimensions to your structural load requirements to ensure stability and prevent structural failures. Ensuring compatibility with existing infrastructure is also essential for seamless integration.

Tips: Always consult technical specifications and local building codes before making a final decision on pipe size and wall thickness. Additionally, consider the context of the installation; for example, underground applications may necessitate thicker walls to withstand soil pressure. Lastly, opt for galvanized options that meet ASTM A53 or A500 standards for assurance of quality and longevity in your projects.

This bar chart displays key characteristics to consider when selecting galvanized rectangular pipes for your project. Each dimension represents an important factor impacting the performance and suitability of the pipes, helping you make informed decisions.

Galvanized rectangular pipes have become indispensable in various industries due to their strength, durability, and resistance to corrosion. These pipes are widely used in construction, manufacturing, and agricultural applications. In construction, they serve as structural support in buildings and frameworks, providing stability and longevity. The manufacturing industry uses galvanized rectangular pipes for creating machinery and equipment, while the agricultural sector employs them for irrigation systems and fencing.

When selecting galvanized rectangular pipes for your project, consider the specific application and load requirements to ensure the right choice. For structural uses, it’s essential to choose pipes that can withstand the forces they're subjected to, such as weight loads and environmental factors. In manufacturing, the thickness and dimensions of the pipe can affect not just performance but also compatibility with other components.

**Tips**: Always verify the pipe’s coating thickness and ensure it meets industry standards to prevent premature rusting. Additionally, when ordering, confirm the specifications of the pipes, as precise measurements will play a crucial role in the success of your projects. Remember to take into account local environmental conditions, as these can greatly influence the performance of galvanized pipes over time.

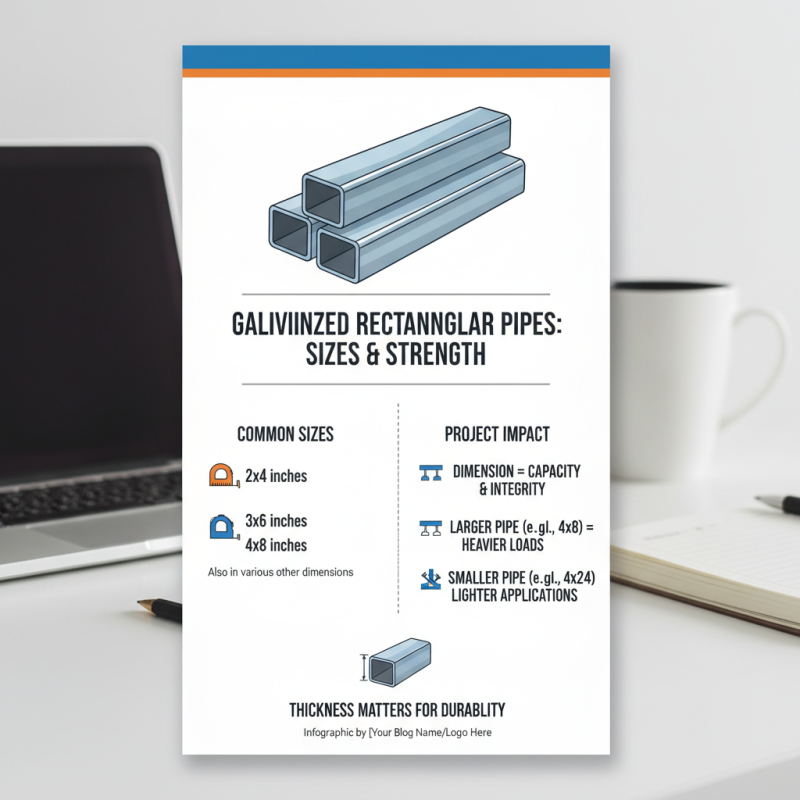

When selecting galvanized rectangular pipes for your project, understanding the standard sizes and thicknesses is essential. Galvanized pipes typically come in various dimensions, including common sizes like 2x4 inches, 3x6 inches, and 4x8 inches. These dimensions not only determine the volume of materials they can carry but also influence the structural integrity of the project. For example, a larger pipe may be necessary for heavier loads, while smaller pipes might suffice for lighter applications.

Tips: Always consider the specific requirements of your project when choosing pipe sizes. Analyze the load-bearing capacity and structural demands to ensure you select an appropriate size and thickness that adheres to safety standards.

Furthermore, the thickness of galvanized rectangular pipes is measured in gauge or millimeters. Thicker pipes provide more strength and durability, making them ideal for heavy-duty applications. Common thicknesses range from 1.5mm to 4mm, with each level providing different levels of stress resistance. It's advisable to consult with a structural engineer if you're uncertain about the thickness needed for your project.

Tips: Perform a thorough assessment of environmental factors such as moisture or chemicals that may affect the pipe's longevity and performance, as this will guide you in choosing the right thickness.

When selecting galvanized rectangular pipes for your project, installation and maintenance considerations are crucial to ensure longevity and performance. Galvanized pipes, known for their corrosion-resistant properties due to a protective zinc coating, require careful handling during installation. According to industry reports, improper installation can reduce a pipe's lifespan significantly, leading to increased costs and project delays.

Tips for installation include ensuring that the pipes are cut accurately to minimize unnecessary joints and fittings, as each joint can potentially become a weak point. Furthermore, proper alignment and support are vital; pipes should be supported to prevent sagging, which can lead to material fatigue and eventual failure. The American Society for Testing and Materials (ASTM) suggests secure mounting every 10 feet to maintain structural integrity.

For maintenance, it is essential to regularly inspect the pipes for any signs of rust or corrosion, especially at joints where water may accumulate, leading to accelerated degradation. A periodical cleaning routine can prevent the build-up of materials that may trap moisture.

As indicated by the National Association of Pipe Fabricators, proactive maintenance extending beyond initial installation can enhance the lifespan of galvanized pipes by up to 30%. This approach not only preserves the integrity of the piping system but also contributes to overall project efficiency.